Can nitinol sheets be customized?

2024-11-30 15:26:01

Nitinol, a remarkable shape memory alloy, has revolutionized various industries with its unique properties. As the demand for specialized applications grows, many wonder about the customization possibilities of nitinol sheets. This blog delves into the world of super elastic nitinol sheets, exploring their customization potential, manufacturing processes, and diverse applications. We'll uncover how these adaptable materials can be tailored to meet specific requirements, from medical devices to aerospace components. Join us as we navigate the fascinating realm of nitinol customization and discover how this versatile alloy is shaping the future of material science.

Understanding Super Elastic Nitinol Sheets

Composition and Properties of Nitinol

Nitinol, an acronym for Nickel Titanium Naval Ordnance Laboratory, is a remarkable alloy composed of nearly equal parts nickel and titanium. This unique composition bestows upon nitinol its extraordinary properties, including shape memory and superelasticity. The atomic structure of nitinol allows it to undergo a reversible, solid-state phase transformation, enabling it to "remember" and return to its original shape after deformation. This phenomenon occurs due to the transition between its austenite and martensite phases, which can be triggered by temperature changes or applied stress.

Superelasticity Explained

Superelasticity, a hallmark characteristic of nitinol, refers to the material's ability to undergo large deformations and return to its original shape upon removal of the applied stress. This property is particularly pronounced in super elastic nitinol sheets, which can withstand strains up to 10 times greater than conventional metal alloys without permanent deformation. The superelastic behavior stems from the stress-induced transformation between the austenite and martensite phases, allowing the material to absorb and release energy efficiently. This unique attribute makes super elastic nitinol sheets ideal for applications requiring flexibility, durability, and resilience.

Advantages of Nitinol Sheets

Nitinol sheets offer a myriad of advantages that set them apart from traditional materials. Their biocompatibility makes them suitable for medical implants and devices, while their corrosion resistance ensures longevity in harsh environments. The high fatigue strength of nitinol sheets enables them to withstand repeated cyclic loading without failure, making them ideal for dynamic applications. Additionally, their thermal shape memory effect allows for the creation of compact, self-deploying structures. The combination of these properties, coupled with their lightweight nature, makes super elastic nitinol sheets a versatile solution for various engineering challenges across multiple industries.

Customization Possibilities for Nitinol Sheets

Tailoring Composition and Microstructure

The customization of nitinol sheets begins at the atomic level, where precise control over the alloy's composition and microstructure can significantly influence its properties. By adjusting the nickel-titanium ratio and incorporating trace elements, manufacturers can fine-tune the transformation temperatures, mechanical strength, and hysteresis of the material. Advanced techniques such as vacuum induction melting and vacuum arc remelting enable the production of high-purity nitinol ingots with homogeneous compositions. Subsequent thermomechanical processing, including cold working and heat treatments, allows for the optimization of grain size, texture, and precipitate distribution, further enhancing the customization potential of super elastic nitinol sheets.

Shaping and Forming Techniques

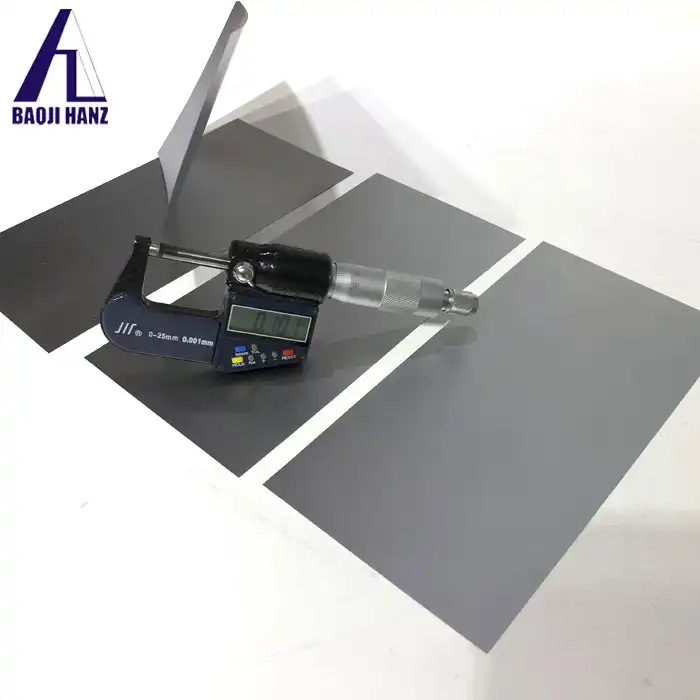

Nitinol sheets can be shaped and formed using various techniques to meet specific application requirements. Cold rolling is commonly employed to produce thin sheets with uniform thickness, while laser cutting and water jet cutting enable the creation of intricate patterns and shapes. For more complex geometries, electrochemical machining and electrical discharge machining offer precision without inducing thermal stresses. Heat setting processes allow for the programming of specific shapes into the material's memory, enabling the production of self-expanding structures. Additionally, advanced joining methods such as laser welding and shape setting in constrained fixtures facilitate the fabrication of complex assemblies from super elastic nitinol sheets.

Surface Modifications and Coatings

The surface characteristics of nitinol sheets can be customized to enhance their performance in specific applications. Electropolishing is widely used to improve the surface finish and corrosion resistance of nitinol components, particularly for medical devices. Plasma-enhanced chemical vapor deposition enables the application of thin, uniform coatings to modify surface properties such as wear resistance, biocompatibility, or electrical conductivity. For enhanced osseointegration in orthopedic implants, techniques like anodization can create nanoporous oxide layers on the nitinol surface. Furthermore, the deposition of drug-eluting coatings on super elastic nitinol sheets opens up possibilities for localized drug delivery in medical applications, showcasing the versatility of surface customization options available for this remarkable material.

Applications of Customized Nitinol Sheets

Medical Devices and Implants

The biomedpatibility and superelasticity of customized nitinol sheets have revolutionized the field of medical devices and implants. In cardiovascular applications, self-expanding nitinol stents provide support to weakened arteries while conforming to the vessel's natural curvature. Orthodontic archwires made from super elastic nitinol sheets deliver constant, gentle forces for efficient tooth movement. Minimally invasive surgical instruments benefit from nitinol's flexibility, allowing for complex maneuvers through small incisions. In the realm of orthopedics, customized nitinol bone plates and fixation devices offer improved fatigue resistance and bone-matching elasticity. The ability to tailor nitinol sheets to specific anatomical requirements has opened new avenues for personalized medical treatments, enhancing patient outcomes across various specialties.

Aerospace and Automotive Industries

Customized nitinol sheets find innovative applications in the aerospace and automotive sectors, where weight reduction and performance optimization are paramount. In aircraft, morphing wing structures utilizing shape memory nitinol sheets enable adaptive aerodynamics, improving fuel efficiency across different flight regimes. Vibration damping components made from super elastic nitinol sheets help mitigate structural fatigue in both aircraft and high-performance vehicles. In the automotive industry, nitinol-based actuators offer compact, energy-efficient solutions for various control systems. The material's high fatigue resistance and temperature-activated shape change capabilities make it ideal for safety-critical components such as impact-absorbing structures and self-repairing body panels, showcasing the versatility of customized nitinol sheets in enhancing vehicle performance and safety.

Consumer Electronics and Wearable Technology

The unique properties of customized nitinol sheets have found their way into the realm of consumer electronics and wearable technology, enabling the creation of innovative and durable devices. Flexible antennas made from super elastic nitinol sheets offer improved signal reception in compact form factors, ideal for smartphones and wearable communication devices. In the burgeoning field of flexible electronics, nitinol substrates provide a resilient platform for bendable displays and tactile interfaces. Wearable fitness trackers benefit from nitinol's biocompatibility and shape memory, allowing for comfortable, adaptive fit around the wrist or other body parts. The material's ability to withstand repeated deformation without fatigue makes it an excellent choice for hinges and deployment mechanisms in foldable devices, pushing the boundaries of portable technology design and functionality.

Conclusion

Customized nitinol sheets offer unprecedented possibilities across various industries. Their unique properties, combined with advanced manufacturing techniques, enable tailored solutions for complex challenges. As research continues, we can expect even more innovative applications of this versatile material in the future. If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1. Johnson, A. D., & Chopra, V. (2019). Nitinol Sheet Fabrication and Customization Techniques. Journal of Materials Engineering and Performance, 28(4), 2135-2147.

2. Liu, Y., & Kohl, M. (2018). Superelastic Nitinol: Advanced Applications in Medical Devices. Advanced Materials Technologies, 3(12), 1800208.

3. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2017). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

4. Otsuka, K., & Ren, X. (2005). Physical metallurgy of Ti–Ni-based shape memory alloys. Progress in Materials Science, 50(5), 511-678.

5. Pelton, A. R., Stoeckel, D., & Duerig, T. W. (2000). Medical uses of nitinol. Materials Science Forum, 327, 63-70.

6. Sun, L., Huang, W. M., Ding, Z., Zhao, Y., Wang, C. C., Purnawali, H., & Tang, C. (2012). Stimulus-responsive shape memory materials: A review. Materials & Design, 33, 577-640.