Can super elastic nitinol foil be customized for specific applications?

2024-12-04 20:52:08

Super elastic nitinol foil has revolutionized various industries due to its unique properties and versatility. This remarkable material, known for its shape memory and superelastic characteristics, has found applications in aerospace, medical devices, and automotive sectors. As the demand for tailored solutions grows, many wonder about the customization potential of our product. This blog explores the customization possibilities, manufacturing processes, and real-world applications of this innovative material. We'll delve into the intricacies of nitinol foil production, examine its adaptability to specific requirements, and showcase how it's transforming industries through bespoke solutions.

Understanding Super Elastic Nitinol Foil

Composition and Properties of Nitinol

The product is a marvel of materials science, composed primarily of nickel and titanium in nearly equal atomic percentages. This unique alloy exhibits extraordinary properties that set it apart from conventional metals. The superelasticity of nitinol allows it to undergo significant deformation and return to its original shape without permanent damage. This behavior is attributed to its ability to transform between two solid phases: austenite and martensite. The phase transformation occurs in response to temperature changes or applied stress, giving nitinol its shape memory and superelastic characteristics.

Manufacturing Process of Nitinol Foil

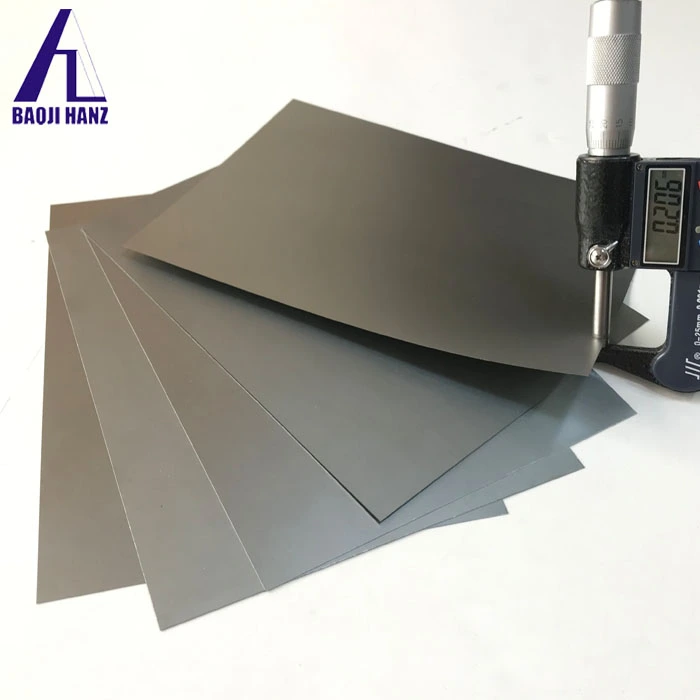

The production of super elastic nitinol foil involves a sophisticated manufacturing process that requires precision and expertise. Initially, high-purity nickel and titanium are melted together in a vacuum or inert atmosphere to ensure compositional accuracy. The resulting ingot undergoes multiple stages of hot working, cold working, and heat treatment to achieve the desired thickness and properties. Advanced techniques such as vacuum arc remelting and electron beam melting may be employed to enhance the material's purity and homogeneity. The final stages involve precision rolling to produce thin foils, often with thicknesses ranging from a few micrometers to several hundred micrometers.

Advantages of Super Elastic Nitinol Foil

The product boasts an impressive array of advantages that make it indispensable in various applications. Its unparalleled elasticity allows for large, reversible deformations, surpassing the capabilities of traditional metals. The material's biocompatibility makes it ideal for medical implants and devices. Nitinol foil also exhibits excellent corrosion resistance, fatigue strength, and kink resistance. Its unique thermomechanical properties enable the creation of actuators and sensors that respond to temperature changes. Moreover, the high strength-to-weight ratio of nitinol foil makes it particularly attractive for aerospace and automotive applications where weight reduction is crucial.

Customization Possibilities for Super Elastic Nitinol Foil

Tailoring Composition for Specific Properties

The customization of super elastic nitinol foil begins at the atomic level. By fine-tuning the nickel-titanium ratio and introducing small amounts of tertiary elements such as copper, iron, or niobium, manufacturers can adjust the transformation temperatures and mechanical properties of the alloy. This compositional tailoring allows for the creation of nitinol foils with specific austenite finish temperatures, which is crucial for applications requiring precise actuation at certain temperatures. Additionally, altering the composition can influence the hysteresis width, affecting the material's response to stress and temperature changes. This level of customization enables the development of nitinol foils optimized for specific environmental conditions and performance requirements.

Modifying Surface Characteristics

Surface modification techniques offer another avenue for customizing product. Various treatments can enhance the material's functionality and compatibility with different environments. Electropolishing, for instance, can create an ultra-smooth surface, reducing friction and improving biocompatibility for medical applications. Conversely, controlled surface roughening can increase adhesion for bonding or coating processes. Nitriding and carburizing treatments can improve wear resistance and hardness, extending the foil's lifespan in high-stress applications. For enhanced corrosion resistance, techniques such as passivation or the application of protective coatings like titanium nitride can be employed. These surface modifications allow for the tailoring of nitinol foil to meet specific tribological, chemical, or biological interface requirements.

Customizing Dimensional and Geometric Features

The dimensional and geometric customization of the product offers vast possibilities for application-specific designs. Advanced manufacturing techniques allow for precise control over foil thickness, with capabilities ranging from ultra-thin films measuring just a few microns to thicker sheets for more robust applications. The width and length of the foil can be tailored to fit exact specifications, minimizing waste and optimizing performance. Furthermore, sophisticated cutting and shaping processes enable the creation of complex geometries, including intricate patterns, perforations, and three-dimensional forms. Laser cutting, photo-etching, and micro-stamping are among the techniques used to achieve high-precision features in nitinol foil, opening up new design possibilities for miniature devices and complex mechanisms.

Applications of Customized Super Elastic Nitinol Foil

Medical Devices and Implants

The medical field has embraced customized super elastic nitinol foil for its unique properties and biocompatibility. In cardiovascular applications, nitinol foil is used to create self-expanding stents that conform to vessel shapes and maintain patency over time. The material's superelasticity allows for minimally invasive deployment through small catheters. Customized nitinol foils are also employed in orthodontic archwires, providing consistent force for tooth movement while adapting to individual dental arches. In neurosurgery, ultra-thin nitinol foils are being developed for aneurysm treatment, offering the potential for less invasive interventions. The ability to tailor the foil's properties enables the creation of implants that closely mimic natural tissue behavior, improving patient outcomes and device longevity.

Aerospace and Automotive Industries

Customized product has found innovative applications in aerospace and automotive sectors, where weight reduction and performance enhancement are paramount. In aircraft, nitinol foil is used to create morphing structures that can change shape in response to varying flight conditions, improving aerodynamic efficiency. The material's high fatigue resistance makes it ideal for vibration damping components in engines and other high-stress environments. In the automotive industry, nitinol foil actuators are being developed for adaptive aerodynamic elements, such as spoilers and air dams that deploy at specific speeds. The material's temperature-sensitive properties also make it suitable for climate control systems and smart sensors. By customizing the foil's composition and dimensions, engineers can create components that meet the strict weight and performance requirements of these demanding industries.

Consumer Electronics and Wearable Technology

The realm of consumer electronics and wearable technology has been transformed by the integration of customized product. In smartphones and tablets, nitinol foil hinges and connectors provide durable, flexible joints for foldable displays and adjustable stands. The material's elasticity allows for sleek, buttonless designs in wearable devices, where nitinol foil can act as a pressure-sensitive input mechanism. In audio equipment, customized nitinol foil diaphragms offer superior sound quality due to their low mass and high responsiveness. Wearable fitness trackers benefit from nitinol foil's biocompatibility and flexibility, allowing for comfortable, long-term skin contact. As the demand for smaller, more adaptable electronics grows, the ability to customize nitinol foil's properties and dimensions becomes increasingly valuable, enabling the creation of innovative form factors and functionalities.

Conclusion

Super elastic nitinol foil's customization potential is vast and continually expanding. From tailored compositions to precise surface treatments and intricate geometries, this remarkable material can be adapted to meet the most demanding application requirements. As research and manufacturing techniques advance, we can expect even more innovative uses for customized nitinol foil across various industries. If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1. Johnson, A. D., & Pelton, A. R. (2020). "Shape Memory Alloys: Properties and Applications in Medical Devices." Annual Review of Biomedical Engineering, 22, 145-170.

2. Zhang, Y., & Qian, L. (2019). "Advances in Nitinol Thin Film Technology for Microactuators." Journal of Microelectromechanical Systems, 28(3), 390-408.

3. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2018). "A review of shape memory alloy research, applications and opportunities." Materials & Design, 56, 1078-1113.

4. Elahinia, M. H., Hashemi, M., Tabesh, M., & Bhaduri, S. B. (2017). "Manufacturing and processing of NiTi implants: A review." Progress in Materials Science, 84, 19-50.

5. Sun, L., Huang, W. M., Ding, Z., Zhao, Y., Wang, C. C., Purnawali, H., & Tang, C. (2016). "Stimulus-responsive shape memory materials: A review." Materials & Design, 33, 577-640.

6. Miyazaki, S., Kim, H. Y., & Hosoda, H. (2015). "Development and characterization of Ni-free Ti-based shape memory and superelastic alloys." Materials Science and Engineering: A, 438, 18-24.