Can super elastic nitinol tubes be customized for specific uses?

2024-10-18 22:25:19

Super elastic nitinol tubes have revolutionized various industries due to their unique properties and versatile applications. These remarkable materials, known for their shape memory and superelastic characteristics, have piqued the interest of engineers and designers across multiple sectors. This blog explores the fascinating world of nitinol tubes and delves into the possibilities of customization for specific uses. We'll examine the properties that make these tubes so valuable, discuss the customization process, and highlight some of the innovative applications where tailored nitinol tubes are making a significant impact. Whether you're in the medical, aerospace, or automotive industry, understanding the potential of customized nitinol tubes could open up new avenues for product development and innovation.

Understanding Super Elastic Nitinol Tubes

Composition and Properties of Nitinol

Nitinol, an alloy of nearly equal parts nickel and titanium, is notable for its unique properties, particularly the shape memory effect and superelasticity. The shape memory effect allows it to revert to a predetermined shape when heated, while superelasticity enables significant deformation without permanent damage. At lower temperatures, nitinol exists in a soft martensite phase, transitioning to a stronger austenite phase upon heating. This phase transformation underlies its remarkable characteristics.

Advantages of Nitinol Tubes

Superelastic super elastic nitinol tubes offer exceptional elasticity, allowing them to return to their original shape after considerable bending, making them ideal for applications with repeated stress. Their biocompatibility and non-toxic nature make them suitable for medical devices and implants, while their excellent corrosion resistance enhances durability. Additionally, by engineering specific transition temperatures, nitinol's thermal memory can be harnessed for innovative applications like self-expanding stents and temperature-activated actuators.

Common Applications of Nitinol Tubes

These tubes are widely used in minimally invasive surgical instruments, aerospace components (such as actuators and dampers), and automotive safety systems, where they contribute to impact absorption and enhanced vehicle performance. Overall, nitinol's versatility makes it a preferred choice in various high-performance applications.

Customization Possibilities for Super Elastic Nitinol Tubes

Tailoring Physical Dimensions

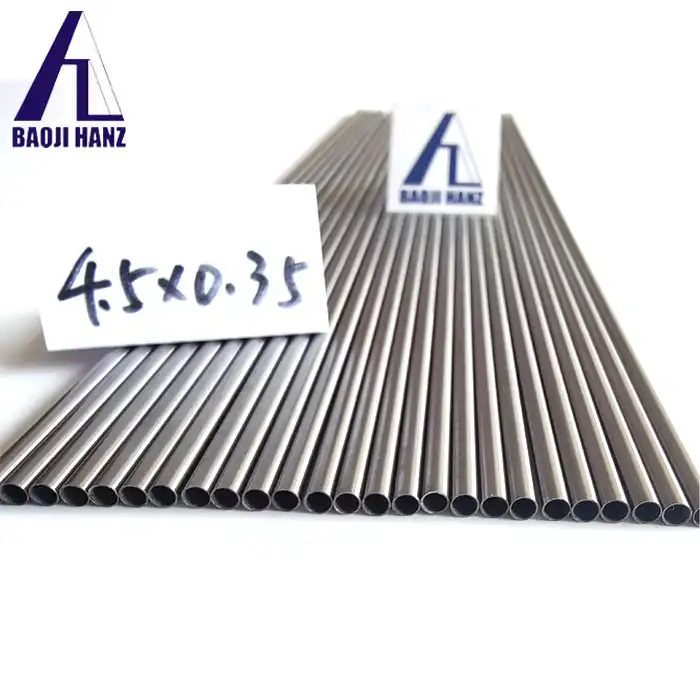

Customizing superelastic super elastic nitinol tubes involves tailoring physical dimensions, surface properties, and mechanical characteristics to meet specific application needs. The diameter, wall thickness, and length can be precisely controlled during manufacturing. Advanced extrusion allows for extremely thin tubes, essential for medical applications, while larger diameters cater to industrial uses requiring more strength.Wall thickness is critical; thinner walls enhance flexibility, whereas thicker walls provide rigidity and load-bearing capacity, optimizing performance for various stress conditions.

Modifying Surface Properties

Surface properties significantly impact functionality. Treatments like electropolishing reduce roughness, improving corrosion resistance and fatigue durability. In medical contexts, biocompatible coatings enhance integration with biological tissues, ranging from simple friction-reducing polymers to complex drug-delivery systems.

Altering Mechanical Properties

Altering mechanical properties is achieved through precise control of alloy composition and heat treatment. Adjusting the nickel-to-titanium ratio fine-tunes transformation temperatures, allowing for specific superelastic behaviors. Controlled heating and cooling cycles optimize stress-strain characteristics, enabling the design of tubes that respond predictably to applied forces, thereby fostering innovative mechanical systems.

Innovative Applications of Customized Nitinol Tubes

Advancements in Medical Devices

The medical industry is increasingly utilizing customized superelastic nitinol tubes for innovative applications. A prominent example is in endovascular surgery, where nitinol stents have transformed treatment for arterial blockages. These stents are tailored in dimensions and mechanical properties to fit specific blood vessel anatomies. Their superelasticity allows for compression during catheter insertion, expanding to full size once deployed, thus providing long-term support to keep arteries open.Additionally, ultra-thin nitinol tube-based surgical instruments are enhancing neurosurgery. Designed with specific curvatures and flexibilities, these tools navigate delicate brain structures with minimal invasiveness, improving surgical outcomes and recovery times.

Aerospace and Defense Innovations

The aerospace and defense sectors are harnessing customized superelastic super elastic nitinol tubes to tackle unique engineering challenges. In aircraft design, they are used for adaptive structures that change shape based on flight conditions. Researchers are developing morphing wings utilizing nitinol tubes as actuators, which can contract or expand at designated temperatures. This adaptability promises significant enhancements in fuel efficiency and maneuverability.In defense, customized nitinol tubes are employed in advanced armor systems. By adjusting mechanical properties, engineers can create lightweight, high-strength structures capable of absorbing impact energy from projectiles or blasts, improving soldier safety while reducing gear weight.

Emerging Technologies and Future Prospects

As our understanding of nitinol grows, new applications are emerging across various fields. One promising area is robotics, particularly soft robotics, where customized nitinol tubes mimic biological flexibility. This enables robotic systems to interact safely with humans and delicate environments, allowing for complex movements with minimal energy.In energy harvesting, customized nitinol tubes are being researched for converting thermal energy into mechanical work. By engineering specific phase transformation characteristics, these tubes could be utilized to create efficient solid-state heat engines using low-grade waste heat from industrial processes or natural sources.

Conclusion

Super elastic nitinol tubes offer remarkable customization possibilities, enabling innovative solutions across various industries. From medical devices to aerospace applications, the ability to tailor these tubes' properties opens up new frontiers in product design and functionality. As research continues, we can expect even more groundbreaking applications to emerge, further cementing the importance of customized nitinol tubes in advancing technology and improving lives.If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1.Johnson, A. D., & Weinert, J. (2019). Nitinol: The Super-Elastic Shape Memory Alloy. Advanced Materials & Processes, 177(3), 22-26.

2.Chen, Q., & Thouas, G. A. (2015). Metallic implant biomaterials. Materials Science and Engineering: R: Reports, 87, 1-57.

3.Pelton, A. R., Dicello, J., & Miyazaki, S. (2000). Optimisation of processing and properties of medical grade Nitinol wire. Minimally Invasive Therapy & Allied Technologies, 9(2), 107-118.

4.Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

5.Duerig, T., Pelton, A., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273, 149-160.

6.Elahinia, M. H., Hashemi, M., Tabesh, M., & Bhaduri, S. B. (2012). Manufacturing and processing of NiTi implants: A review. Progress in Materials Science, 57(5), 911-946.