Does nitinol sheet thickness matter?

2024-07-19 17:54:58

Why is Nitinol Sheet Thickness Important?

The thickness of a nitinol sheet can significantly impact its mechanical properties and functionality. For instance, in medical devices such as stents and guidewires, the thickness of the nitinol sheet can affect its flexibility and strength. Thicker sheets may provide more strength but at the expense of flexibility, while thinner sheets offer greater flexibility but may not be as strong.

Additionally, in the field of aerospace, where nitinol is used for its shape memory properties, the thickness of the sheet can determine the efficiency of the shape memory effect. Thicker sheets may require more heat to activate the shape memory effect, whereas thinner sheets can achieve this with less energy. This can be crucial in applications where energy efficiency is a priority.

Furthermore, the thickness of nitinol sheets can also influence their fatigue resistance. In applications where the material is subjected to repeated stress cycles, such as in actuators or robotic components, the optimal thickness can ensure longer-lasting performance.

How Does the Thickness of Nitinol Sheets Affect Their Application in Medical Devices?

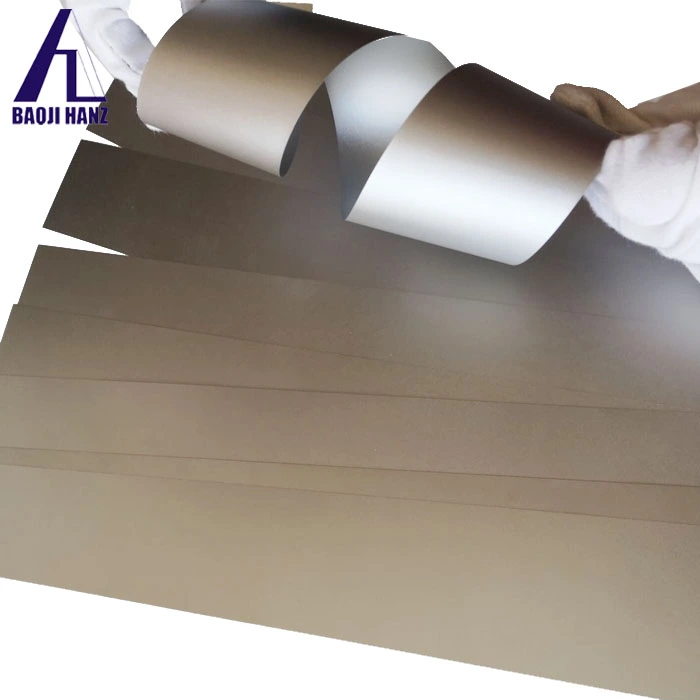

In the medical field, the thickness of nitinol sheets is a critical factor that can influence the design and effectiveness of medical devices. Custom Nitinol Sheets and Tailored Nitinol Sheets are often used to create devices like stents, which need to be both flexible and strong enough to withstand the forces within the human body.

For example, in cardiovascular stents, the thickness of the nitinol sheet must be carefully chosen to balance flexibility and radial strength. A stent that is too thick may be difficult to navigate through the vascular system, while one that is too thin may not provide adequate support to keep the artery open. Thus, the thickness of the nitinol sheet must be optimized to achieve the desired performance.

Similarly, in orthopedic implants, the thickness of the nitinol sheet can affect the implant's ability to conform to the bone structure and provide the necessary support. Thicker sheets may offer more support but could also lead to increased stiffness, which might not be ideal for certain applications.

Can the Thickness of Nitinol Sheets Impact Their Performance in Industrial Applications?

In industrial applications, the thickness of nitinol sheets plays a vital role in determining their suitability for specific tasks. Tailored Nitinol Sheets are often used in actuators, sensors, and other components that require precise control over their mechanical properties.

For actuators, the thickness of the nitinol sheet can affect the force and displacement generated by the actuator. Thicker sheets can produce more force but may have a reduced range of motion, while thinner sheets offer greater flexibility but may generate less force. This trade-off must be considered when designing actuators for specific applications.

In the field of robotics, where nitinol sheets are used for their superelastic properties, the thickness of the sheet can impact the robot's ability to perform tasks that require high flexibility and resilience. Thinner sheets can enhance the robot's dexterity and ability to handle delicate tasks, while thicker sheets provide more structural support for heavier tasks.

Additionally, in the automotive industry, where nitinol sheets are used in various components, the thickness can affect the durability and performance of these components. For example, in shape memory alloys used for adaptive components, the thickness can influence the activation temperature and the response time of the material, which are critical factors in ensuring reliable performance.

What Are the Key Considerations When Choosing the Thickness of Nitinol Sheets?

When selecting the appropriate thickness for nitinol sheets, several factors need to be considered:

-

Application Requirements: The specific requirements of the application, such as flexibility, strength, and fatigue resistance, will dictate the optimal thickness. For medical devices, achieving the right balance between flexibility and strength is crucial, while in industrial applications, the focus might be on force generation and range of motion.

-

Material Properties: The inherent properties of nitinol, such as its shape memory and superelasticity, must be taken into account. Thicker sheets may require more energy to activate the shape memory effect, while thinner sheets can achieve this more efficiently.

-

Manufacturing Constraints: The manufacturing process can also influence the choice of thickness. For example, producing very thin nitinol sheets may be more challenging and costly, which could impact the overall feasibility of the design.

-

Environmental Factors: The operating environment, including temperature and exposure to corrosive elements, can affect the performance of nitinol sheets. Thicker sheets may offer better resistance to environmental stressors, while thinner sheets might be more susceptible to damage.

By carefully considering these factors, engineers and designers can select the appropriate thickness of nitinol sheets to ensure optimal performance in their specific applications.

Conclusion

The thickness of nitinol sheets is a critical factor that can significantly impact their performance in various applications. Whether it's in medical devices, industrial components, or other high-tech fields, choosing the right thickness is essential to achieving the desired balance of flexibility, strength, and durability. Custom Nitinol Sheets and Tailored Nitinol Sheets offer the versatility needed to meet these diverse requirements, making nitinol an invaluable material in many advanced technologies.

References

- "Nitinol Properties and Applications". ASM International.

- "Medical Device Design: Innovation from Concept to Market". Peter J. Ogrodnik.

- "Shape Memory Alloys: Modeling and Engineering Applications". Dimitris C. Lagoudas.

- "Nitinol in Medical Devices: The Ultimate User's Guide". Michael Frotscher.

- "Engineering Aspects of Shape Memory Alloys". T. W. Duerig, K. N. Melton, D. Stöckel, C. M. Wayman.

- "Shape Memory Materials". K. Otsuka, C. M. Wayman.

- "Biomedical Engineering Handbook". Joseph D. Bronzino.

- "Nitinol Alloys: Current and Potential Biomedical Applications". Materials Science and Engineering C.

- "Fatigue and Fracture of Nitinol". International Journal of Fatigue.

- "Advances in Shape Memory Alloy Technology". Springer Series in Materials Science.