How do shape memory nitinol tubes work?

2024-09-27 19:54:25

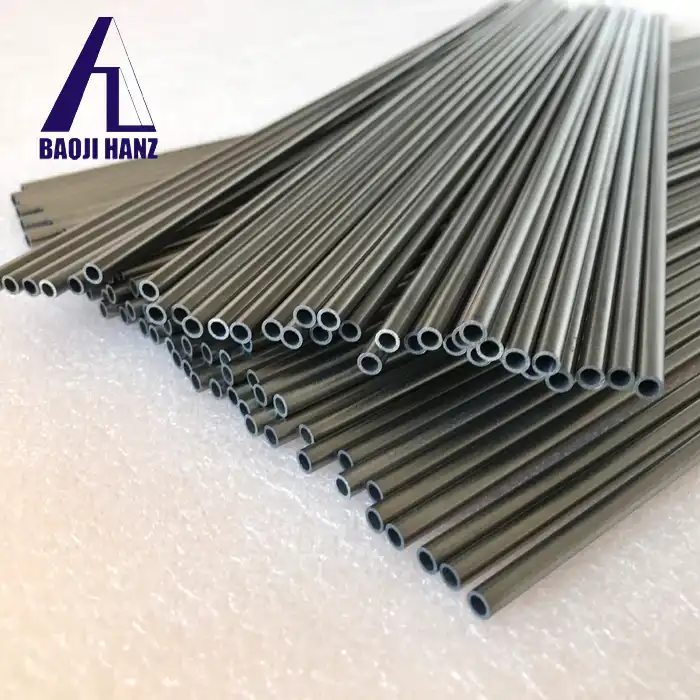

Shape memory nitinol tubes are a fascinating innovation in materials science, combining unique properties that make them invaluable in various industries. These tubes, made from a nickel-titanium alloy, possess the remarkable ability to "remember" and return to their original shape after deformation. This blog explores the intricate workings of nitinol tubes, delving into their structure, properties, and mechanisms that enable their shape-shifting capabilities. We'll uncover the science behind their behavior, discuss their applications across different sectors, and examine the factors that influence their performance. Whether you're an engineer, researcher, or simply curious about cutting-edge materials, this comprehensive guide will provide valuable insights into the world of tubes.

The Science Behind Shape Memory Nitinol Tubes

Crystal Structure and Phase Transformations

The products owe their unique properties to the crystal structure of the nickel-titanium alloy. At high temperatures, nitinol exists in an austenite phase, characterized by a cubic crystal structure. As the temperature decreases, the material undergoes a phase transformation to a martensite phase, which has a more complex, twinned structure. This phase change is crucial for the shape memory effect and superelasticity of nitinol tubes.

The martensite phase can be easily deformed, allowing the tube to be bent or twisted into various shapes. However, when heated above its transformation temperature, the material reverts to the austenite phase, causing it to "remember" and return to its original shape. This transformation occurs without any macroscopic change in the material's volume, making it ideal for applications requiring precise and repeatable movements.

Thermomechanical Behavior

The thermomechanical behavior of shape memory nitinol tubes is a key factor in their functionality. When a nitinol tube is cooled below its martensite finish temperature (Mf), it can be deformed with relatively little force. Upon heating above its austenite finish temperature (Af), the tube will recover its original shape, exerting a significant force in the process. This behavior is governed by the material's transformation temperatures, which can be tailored during the manufacturing process by adjusting the nickel-titanium ratio and incorporating other alloying elements. The precise control of these temperatures allows engineers to design nitinol tubes that respond to specific thermal conditions, making them suitable for a wide range of applications.

Superelasticity and Stress-Induced Transformations

In addition to the shape memory effect, nitinol tubes exhibit superelasticity, a property that allows them to undergo large deformations and return to their original shape upon unloading. This behavior occurs when the material is above its austenite finish temperature and is subjected to mechanical stress. As stress is applied, the austenite phase transforms into stress-induced martensite, allowing the tube to deform. When the stress is removed, the martensite reverts to austenite, and the tube returns to its original shape. This stress-induced transformation enables nitinol tubes to withstand large strains without permanent deformation, making them ideal for applications requiring flexibility and durability.

Applications of Shape Memory Nitinol Tubes

Medical Devices and Implants

Shape memory nitinol tubes have revolutionized the medical industry, particularly in the field of minimally invasive surgeries. Their unique properties make them ideal for creating self-expanding stents, which can be compressed into a small diameter for insertion into blood vessels and then expand to their predetermined shape once in place. This capability reduces the need for invasive procedures and improves patient outcomes.

Nitinol tubes are also used in orthodontic archwires, where their superelastic properties allow for the application of constant, gentle forces to move teeth. In the realm of orthopedic implants, these tubes can be used to create dynamic fixation devices that adapt to bone growth and healing, promoting better recovery and reducing complications.

Aerospace and Automotive Industries

The aerospace sector has embraced our products for their potential in creating morphing structures and actuators. These tubes can be used to develop adaptive aircraft components that change shape in response to different flight conditions, improving aerodynamic performance and fuel efficiency. In space applications, nitinol tubes are employed in deployable structures, such as antennas and solar panels, which can be compactly stored during launch and then expand to their functional shape in orbit.

Consumer Electronics and Robotics

The consumer electronics market has also benefited from the unique properties of our products. These tubes are used in smartphone antennas, providing a compact and durable solution that can withstand repeated bending and twisting. In laptop hinges, nitinol tubes offer a smooth, controlled movement and can be designed to maintain a specific position without additional locking mechanisms.

In the field of robotics, nitinol tubes are enabling the development of soft robotics and biomimetic systems. Their ability to produce smooth, lifelike movements makes them ideal for creating artificial muscles and flexible manipulators. These applications are pushing the boundaries of robot design, allowing for more adaptable and versatile machines that can interact safely with humans and delicate objects.

Factors Influencing the Performance of Shape Memory Nitinol Tubes

Composition and Heat Treatment

The performance of shape memory nitinol tubes is heavily influenced by their composition and heat treatment. The ratio of nickel to titanium in the alloy affects the transformation temperatures and the mechanical properties of the material. Precise control of this composition during manufacturing is crucial for achieving the desired behavior in specific applications.

Heat treatment plays a vital role in setting the shape memory effect and determining the final properties of the nitinol tubes. Processes such as annealing and aging can be used to fine-tune the transformation temperatures, adjust the recovery forces, and improve the fatigue resistance of the material. The optimal heat treatment parameters depend on the intended application and the desired characteristics of the tubes.

Surface Finish and Processing

The surface condition of our products can significantly impact their performance and biocompatibility. Various surface treatments, such as electropolishing, passivation, and coating, can be applied to enhance corrosion resistance, reduce friction, and improve biocompatibility for medical applications. These treatments can also affect the fatigue life and long-term stability of the tubes.

Environmental Factors and Cyclic Loading

The performance of nitinol tubes can be affected by environmental factors such as temperature fluctuations, humidity, and exposure to corrosive substances. Understanding these influences is crucial for designing reliable systems that can operate in diverse conditions. In medical applications, the biological environment and potential interactions with body fluids must be carefully considered to ensure long-term stability and safety.

Conclusion

Shape memory nitinol tubes represent a remarkable advancement in materials science, offering unique capabilities that are transforming various industries. Their ability to remember and return to a predetermined shape, combined with superelastic properties, opens up a world of possibilities for innovative applications. As research continues and manufacturing techniques improve, we can expect to see even more exciting developments in the field of shape memory alloys, pushing the boundaries of what's possible in engineering and design. If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1.Otsuka, K., & Wayman, C. M. (Eds.). (1998). Shape memory materials. Cambridge university press.

2.Duerig, T., Pelton, A., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273, 149-160.

3.Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

4.Sun, L., Huang, W. M., Ding, Z., Zhao, Y., Wang, C. C., Purnawali, H., & Tang, C. (2012). Stimulus-responsive shape memory materials: a review. Materials & Design, 33, 577-640.

5.Lagoudas, D. C. (Ed.). (2008). Shape memory alloys: modeling and engineering applications. Springer Science & Business Media.

6.Morgan, N. B. (2004). Medical shape memory alloy applications—the market and its products. Materials Science and Engineering: A, 378(1-2), 16-23.