How is shape memory nitinol foil manufactured?

2024-10-18 22:37:40

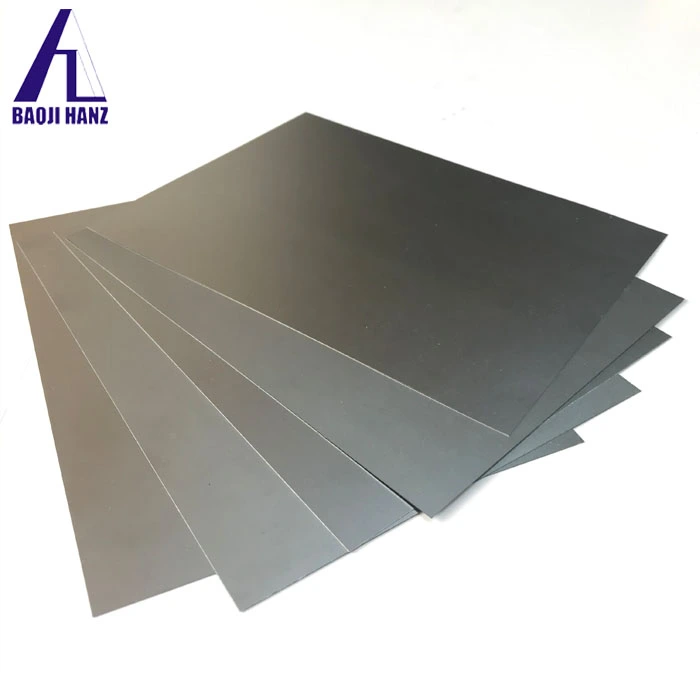

Shape memory nitinol foil is a remarkable material that has revolutionized various industries, from aerospace to medical devices. This innovative alloy possesses unique properties, including the ability to return to its original shape after deformation when exposed to specific temperatures. Understanding the intricate manufacturing process of shape memory nitinol foil is crucial for those seeking to harness its exceptional capabilities. In this comprehensive guide, we'll delve into the fascinating world of nitinol production, exploring the steps involved in creating this versatile material and shedding light on the advanced techniques employed by industry leaders like Baoji Hanz Metal Material Co., Ltd.

Raw Material Selection and Preparation

Sourcing High-Purity Nickel and Titanium

Shape memory nitinol foil's production begins with the careful selection of raw materials, of which high-purity nickel and titanium are crucial components. To ensure that the final product meets stringent quality standards, manufacturers like Baoji Hanz Metal Material Co., Ltd. place an emphasis on sourcing nickel and titanium of the highest possible grade. In order to accomplish this, these raw materials go through stringent testing procedures to confirm their chemical composition and purity, both of which are essential for the performance of the alloy. The foundation for producing dependable nitinol foils that can be successfully utilized in a variety of applications, including medical devices, aerospace components, and smart technologies, is laid by ensuring quality at this initial stage.

Precise Alloying Process

The nitinol alloy is made by carefully combining the raw materials in precise proportions once they are obtained. The final product's shape-memory properties are heavily dependent on the precise ratio of nickel to titanium. As this blend maximizes the unique properties of the alloy, it is typically made up of approximately 55% nickel and 45% titanium by weight. However, even the tiniest variations in this ratio can result in significant variations in the Shape memory nitinol foil's transformation temperatures and mechanical properties. The significance of precise formulation in achieving the desired performance for various applications, such as actuators and medical devices, is highlighted by this sensitivity to composition.

Melting and Homogenization

The alloying process begins with melting the nickel and titanium in a vacuum induction furnace, a critical step that ensures a homogeneous mixture while preventing contamination from external elements. This controlled environment allows for precise temperature management, promoting optimal alloy formation. Once melted, the molten alloy is carefully cooled to form ingots, which serve as the foundational material for further processing. These ingots then undergo additional homogenization treatments, aimed at achieving a uniform distribution of elements throughout the material. This step is essential for ensuring consistent shape memory behavior and mechanical properties, ultimately enhancing the performance and reliability of the nitinol foil in various applications.

Foil Formation and Processing

Hot Working and Cold Rolling

The nitinol ingots are subjected to a series of hot working processes, including forging and rolling, to break down the cast structure and improve the material's ductility. This step is crucial in preparing the alloy for subsequent cold rolling operations. The hot-worked material is then cooled and subjected to multiple passes of cold rolling to achieve the desired foil thickness. Cold rolling not only reduces the material's thickness but also introduces work hardening, which influences the shape memory properties.

Intermediate Annealing

Throughout the cold rolling process, intermediate annealing steps are performed to relieve internal stresses and maintain the material's workability. These annealing treatments are carefully controlled to avoid altering the alloy's composition or introducing unwanted phases. The temperature and duration of annealing are optimized to achieve the desired balance between workability and final shape memory characteristics.

Precision Thickness Control

Achieving the precise thickness of shape memory nitinol foil requires advanced rolling equipment and meticulous process control. Manufacturers like Baoji Hanz Metal Material Co., Ltd. employ sophisticated rolling mills equipped with high-precision sensors and automated control systems. These systems ensure that the foil thickness remains consistent throughout the production run, often achieving tolerances as tight as ±0.0005 mm.

Shape Memory Property Induction and Finishing

Heat Treatment for Shape Memory Effect

The shape memory effect in nitinol foil is induced through a carefully controlled heat treatment process. This crucial step involves heating the foil to a specific temperature, typically between 450°C and 550°C, for a predetermined duration. The exact parameters of this heat treatment are tailored to achieve the desired transformation temperatures and shape memory characteristics. Advanced furnaces with precise temperature control and inert atmospheres are utilized to prevent oxidation during this critical stage.

Surface Treatment and Passivation

After heat treatment, the Shape memory nitinol foil undergoes surface treatment to enhance its corrosion resistance and biocompatibility. This often involves chemical etching to remove surface impurities and create a uniform oxide layer. A passivation process may also be employed to further improve the foil's resistance to corrosion. These surface treatments are particularly important for applications in medical devices and other corrosive environments.

Quality Control and Testing

The final stage of shape memory nitinol foil manufacturing involves rigorous quality control measures. Each batch of foil is subjected to a battery of tests to verify its mechanical properties, transformation temperatures, and shape memory behavior. Advanced testing equipment, such as differential scanning calorimeters and tensile testing machines, are used to characterize the material's performance. Manufacturers like Baoji Hanz Metal Material Co., Ltd. maintain strict quality assurance protocols to ensure that every piece of nitinol foil meets or exceeds industry standards.

Conclusion

The manufacture of shape memory nitinol foil is a complex process that requires expertise, precision, and advanced technology. From raw material selection to final quality control, each step plays a crucial role in producing this remarkable material. As industry leaders continue to innovate and refine their techniques, the potential applications for shape memory nitinol foil continue to expand, promising exciting developments across various sectors. If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1. Otsuka, K., & Wayman, C. M. (Eds.). (1999). Shape memory materials. Cambridge University Press.

2. Pelton, A. R., Stöckel, D., & Duerig, T. W. (2000). Medical uses of nitinol. Materials Science Forum, 327, 63-70.

3. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

4. Morgan, N. B. (2004). Medical shape memory alloy applications—the market and its products. Materials Science and Engineering: A, 378(1-2), 16-23.

5. Miyazaki, S., Fu, Y. Q., & Huang, W. M. (Eds.). (2009). Thin film shape memory alloys: fundamentals and device applications. Cambridge University Press.

6. Frick, C. P., Ortega, A. M., Tyber, J., Maksound, A. E. M., Maier, H. J., Liu, Y., & Gall, K. (2005). Thermal processing of polycrystalline NiTi shape memory alloys. Materials Science and Engineering: A, 405(1-2), 34-49.