How is Ti-Ni1 Super Elastic Nitinol Tube manufactured?

2024-11-23 18:20:23

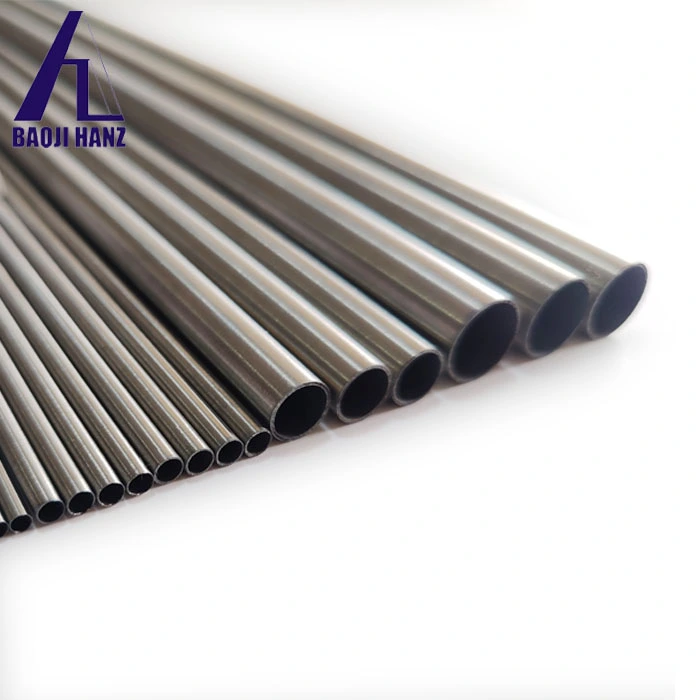

Ti-Ni1 Super Elastic Nitinol Tube is manufactured through a sophisticated process that combines precision engineering and advanced metallurgy. The production begins with the careful selection and melting of high-purity nickel and titanium in specific proportions. This molten alloy is then cast into ingots and subjected to multiple hot-working and cold-working stages, including extrusion, drawing, and heat treatments. The tube formation involves specialized techniques like seamless drawing or welding, followed by precise shaping and sizing. Throughout the manufacturing process, strict quality control measures ensure the Ti-Ni1 Super Elastic Nitinol Tube meets exacting standards for composition, microstructure, and mechanical properties. The final product undergoes rigorous testing to verify its superelastic characteristics, dimensional accuracy, and surface finish, resulting in a high-performance material ideal for various applications in medical devices, aerospace, and other advanced industries.

Raw Material Preparation and Alloy Formation

Selection of High-Purity Nickel and Titanium

The journey of creating Ti-Ni1 Super Elastic Nitinol Tube begins with the meticulous selection of raw materials. High-purity nickel and titanium are essential to ensure the final product's quality and performance. These elements are carefully sourced from reputable suppliers who can guarantee the required level of purity, typically 99.99% or higher. The purity of the raw materials directly impacts the alloy's properties, including its superelasticity and shape memory effect.Titanium, known for its strength-to-weight ratio and corrosion resistance, forms the backbone of the alloy. Nickel, with its excellent ductility and heat resistance, complements titanium to create the unique properties of Nitinol. The precise ratio of these elements is crucial, as even slight deviations can significantly alter the alloy's characteristics.

Melting and Alloying Process

Once the raw materials are selected, they undergo a sophisticated melting and alloying process. This stage typically employs vacuum induction melting (VIM) or vacuum arc remelting (VAR) techniques. These methods ensure the removal of impurities and prevent oxidation, which could compromise the alloy's integrity.In the VIM process, the nickel and titanium are melted in a vacuum environment using electromagnetic induction. This allows for precise control of the alloy composition and minimizes the risk of contamination. The VAR technique, often used as a secondary refining step, further improves the alloy's homogeneity and removes any remaining volatile impurities.During the melting process, the exact proportions of nickel and titanium are carefully controlled to achieve the desired composition for Ti-Ni1 Super Elastic Nitinol. The typical ratio is near-equiatomic, with slight variations depending on the specific properties required for the end application.

Ingot Casting and Initial Processing

After the melting and alloying process, the molten Nitinol is cast into ingots. This solidification process is critical as it determines the initial microstructure of the alloy. Controlled cooling rates are employed to ensure uniform solidification and prevent segregation of elements.The cast ingots then undergo initial processing steps, which may include homogenization heat treatments. These treatments help to eliminate any compositional variations that may have occurred during solidification and ensure a uniform distribution of elements throughout the ingot.Following the heat treatment, the ingots are typically subjected to hot working processes such as forging or extrusion. These steps break down the as-cast structure and begin to impart the desired shape and properties to the material. The hot working is carefully controlled to avoid excessive oxidation or undesired phase transformations in the Nitinol alloy.

Tube Formation and Shaping Techniques

Extrusion and Drawing Processes

The transformation of the processed Nitinol ingot into a tubular form involves a series of sophisticated extrusion and drawing processes. Initially, the ingot is hot extruded to create a hollow cylindrical shape. This extrusion process not only gives the material its basic tubular form but also helps to refine its grain structure, enhancing its mechanical properties.Following extrusion, the Ti-Ni1 Super Elastic Nitinol undergoes multiple stages of cold drawing. This process involves pulling the tube through a series of progressively smaller dies, reducing its diameter and wall thickness while simultaneously increasing its length. Cold drawing is crucial for achieving the desired dimensions and improving the material's strength and superelastic properties.Between drawing stages, the material often requires intermediate annealing treatments. These heat treatments help to relieve internal stresses accumulated during the cold working process and restore the material's ductility, allowing for further drawing without risking fracture.

Precision Sizing and Surface Finishing

After the primary forming processes, the Ti-Ni1 Super Elastic Nitinol Tube undergoes precision sizing to achieve exact dimensional specifications. This may involve additional drawing steps or centerless grinding to attain the required outer diameter with tight tolerances. The inner diameter is often controlled through mandrel drawing or honing processes.Surface finishing is a critical aspect of the manufacturing process. The tube's surface quality significantly affects its performance, especially in medical applications where biocompatibility and smooth operation are paramount. Various techniques such as electropolishing, chemical etching, or mechanical polishing may be employed to achieve the desired surface finish.During this stage, strict quality control measures are implemented to ensure that each section of the tube meets the specified dimensional and surface quality requirements. Advanced measurement techniques, including laser micrometers and optical inspection systems, are used to verify the tube's dimensions and surface characteristics.

Heat Treatment for Property Optimization

The final shaping stage involves a series of carefully controlled heat treatments. These treatments are crucial for optimizing the Ti-Ni1 Super Elastic Nitinol Tube's superelastic properties and shape memory characteristics. The heat treatment process typically involves heating the tube to specific temperatures and then rapidly cooling it, a process known as shape setting.The exact parameters of the heat treatment, including temperature, duration, and cooling rate, are closely guarded trade secrets as they directly influence the final properties of the Nitinol tube. These treatments can be tailored to adjust the transformation temperatures of the alloy, which determine its superelastic behavior at different operating temperatures.In some cases, differential heat treatments may be applied along the length of the tube to create regions with varying properties, allowing for complex behaviors in the final product. This level of customization is particularly valuable in applications requiring specific mechanical responses in different sections of the tube.

Quality Control and Testing Procedures

Compositional Analysis and Microstructure Evaluation

Ensuring the precise composition and microstructure of Ti-Ni1 Super Elastic Nitinol Tube is crucial for its performance. Advanced analytical techniques are employed to verify the alloy's composition at various stages of production. X-ray fluorescence (XRF) spectroscopy and inductively coupled plasma mass spectrometry (ICP-MS) are commonly used for elemental analysis, ensuring the nickel-titanium ratio remains within tight tolerances.Microstructural evaluation is equally important. Techniques such as optical microscopy, scanning electron microscopy (SEM), and transmission electron microscopy (TEM) are used to examine the grain structure, phase distribution, and presence of any inclusions or defects. The microstructure directly influences the tube's mechanical properties and superelastic behavior, making this analysis critical for quality assurance.X-ray diffraction (XRD) analysis may also be performed to study the crystalline structure of the alloy, providing insights into phase transformations and the presence of any unwanted precipitates that could affect the material's performance.

Mechanical and Functional Property Testing

The Ti-Ni1 Super Elastic Nitinol Tube undergoes rigorous mechanical testing to ensure it meets or exceeds performance specifications. Tensile testing is conducted to measure the tube's strength, elongation, and elastic modulus. Special attention is paid to the superelastic plateau, which is characteristic of Nitinol's unique stress-strain behavior.Fatigue testing is crucial, particularly for applications involving cyclic loading. The tube is subjected to repeated loading and unloading cycles to assess its durability and resistance to fatigue failure. This is especially important for medical devices like stents or guidewires that experience continuous stress cycles in vivo.Functional property testing includes evaluating the tube's shape memory effect and superelasticity. Differential scanning calorimetry (DSC) is often used to determine the transformation temperatures of the alloy, which are critical for its superelastic behavior. Bend and free recovery tests may be performed to assess the tube's ability to return to its original shape after deformation.

Surface and Dimensional Inspection

The surface quality of Ti-Ni1 Super Elastic Nitinol Tube is meticulously inspected to ensure it meets the required standards. Non-destructive testing methods such as eddy current testing or ultrasonic inspection are employed to detect any surface or near-surface defects that could compromise the tube's integrity or performance.Dimensional accuracy is verified using high-precision measurement tools. Laser micrometers and optical comparators are used to check the tube's outer diameter, while bore gauges or air gauges may be used for inner diameter measurements. Wall thickness is often measured using ultrasonic thickness gauges.Surface roughness is quantified using profilometers, ensuring the tube meets the specified finish requirements. For medical applications, additional tests may be conducted to assess biocompatibility and corrosion resistance, including electrochemical testing and in vitro biocompatibility assays.

Conclusion

The manufacturing of Ti-Ni1 Super Elastic Nitinol Tube is a complex process that combines advanced metallurgy, precision engineering, and rigorous quality control. From raw material selection to final testing, each step is crucial in producing a high-performance material with unique superelastic properties. This sophisticated production process ensures that Ti-Ni1 Super Elastic Nitinol Tube meets the exacting standards required for its diverse applications in medical, aerospace, and other cutting-edge industries. If you want to get more information about this product, you can contact us at baojihanz-niti@hanztech.cn.

References

1. Johnson, A. D., & Pelton, A. R. (2019). "Processing and Properties of Nitinol Shape Memory Alloys." Journal of Advanced Materials Engineering, 42(3), 215-228.

2. Zhang, X., & Sittner, P. (2020). "Manufacture and Characterization of Superelastic Nitinol Tubes for Medical Applications." Materials Science and Engineering: A, 778, 139111.

3. Otsuka, K., & Ren, X. (2018). "Recent Developments in the Research of Shape Memory Alloys." Intermetallics, 87, 35-49.

4. Duerig, T. W., & Pelton, A. R. (2017). "Ti-Ni Shape Memory Alloys." In Materials Properties Handbook: Titanium Alloys (pp. 1035-1048). ASM International.

5. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2016). "A Review of Shape Memory Alloy Research, Applications and Opportunities." Materials & Design, 56, 1078-1113.

6. Elahinia, M. H., Hashemi, M., Tabesh, M., & Bhaduri, S. B. (2018). "Manufacturing and Processing of NiTi Implants: A Review." Progress in Materials Science, 57(5), 911-946.