What are the properties of ASTM F2063 nitinol rods?

2024-12-23 23:13:34

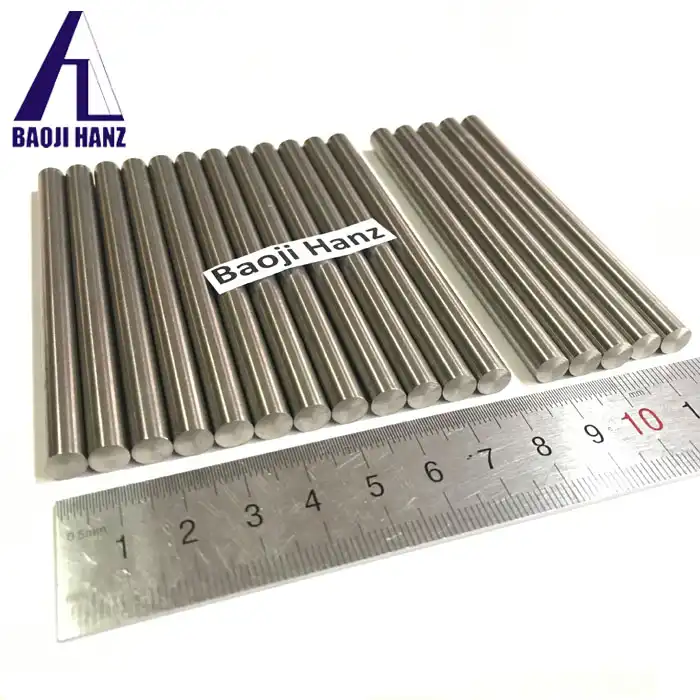

ASTM F2063 nitinol rods are a remarkable material with unique properties that have revolutionized various industries, particularly in medical device manufacturing. These rods, composed of nickel and titanium, exhibit exceptional shape memory and superelasticity, making them ideal for a wide range of applications. In this comprehensive blog post, we'll delve into the fascinating world of ASTM F2063 nitinol rods, exploring their key properties, manufacturing processes, and diverse applications. Whether you're an engineer, researcher, or simply curious about cutting-edge materials, this article will provide valuable insights into the extraordinary capabilities of ASTM F2063 shape memory nitinol rods.

Understanding the Composition and Structure of ASTM F2063 Nitinol Rods

Chemical Composition and Crystal Structure

ASTM F2063 nitinol rods are composed of nearly equiatomic proportions of nickel and titanium. This unique composition results in a crystal structure that can exist in two distinct phases: austenite and martensite. The austenite phase is stable at higher temperatures and has a cubic crystal structure, while the martensite phase is stable at lower temperatures and has a monoclinic crystal structure. The ability to transition between these phases is the key to nitinol's shape memory and superelastic properties.

Phase Transformation Mechanisms

The phase transformation in ASTM F2063 nitinol rods occurs through a diffusionless process known as martensitic transformation. This transformation can be induced by changes in temperature or applied stress. When cooled from the austenite phase, the material transforms into twinned martensite. Upon heating, it reverts to austenite, recovering its original shape. Under stress, the twinned martensite can detwin, allowing for large, reversible deformations.

Microstructure and Grain Size

The microstructure of ASTM F2063 shape memory nitinol rods plays a crucial role in determining their properties. The grain size and orientation can significantly influence the material's behavior. Finer grain sizes generally lead to improved mechanical properties and more stable transformation characteristics. Manufacturers carefully control the processing parameters to achieve the desired microstructure, optimizing the material's performance for specific applications.

Mechanical and Thermal Properties of ASTM F2063 Nitinol Rods

Shape Memory Effect

One of the most remarkable properties of ASTM F2063 nitinol rods is their shape memory effect. This phenomenon allows the material to "remember" and return to a predetermined shape when heated above its transformation temperature. The shape memory effect occurs due to the reversible martensitic transformation. When deformed in the martensite phase, the material can recover its original shape upon heating to the austenite phase. This property enables the design of compact, self-deploying medical devices and actuators.

Superelasticity and Stress-Induced Martensite

Another exceptional property of ASTM F2063 shape memory nitinol rods is superelasticity, also known as pseudoelasticity. This characteristic allows the material to undergo large, reversible deformations without permanent plastic deformation. Superelasticity occurs when the material is above its austenite finish temperature, and stress-induced martensite is formed upon loading. When the stress is removed, the martensite transforms back to austenite, returning the material to its original shape. This property is particularly valuable in applications requiring flexibility and kink resistance, such as guidewires and stents.

Temperature-Dependent Behavior

The mechanical properties of ASTM F2063 nitinol rods are highly temperature-dependent. The material exhibits different behaviors depending on its temperature relative to its transformation temperatures. These transformation temperatures, including the martensite start (Ms), martensite finish (Mf), austenite start (As), and austenite finish (Af) temperatures, can be tailored through composition and processing. Understanding and controlling these temperature-dependent properties is crucial for designing devices that function reliably under specific operating conditions.

Applications and Manufacturing Processes of ASTM F2063 Nitinol Rods

Medical Device Applications

ASTM F2063 nitinol rods have found extensive use in the medical device industry due to their biocompatibility, corrosion resistance, and unique mechanical properties. Some notable applications include:

- Cardiovascular stents that can be compressed for minimally invasive delivery and expand to their designed shape upon deployment

- Orthodontic archwires that provide constant, gentle force for tooth alignment

- Surgical instruments and guidewires that offer flexibility and kink resistance

- Orthopedic implants that can adapt to bone growth and remodeling

The combination of shape memory and superelasticity makes ASTM F2063 nitinol rods ideal for these applications, enabling innovative designs that improve patient outcomes and surgical procedures.

Manufacturing Techniques

Producing high-quality ASTM F2063 nitinol rods requires specialized manufacturing techniques to achieve the desired properties and performance. Some key manufacturing processes include:

- Vacuum induction melting and vacuum arc remelting to ensure high purity and homogeneity

- Hot working and cold drawing to achieve the desired rod dimensions and mechanical properties

- Heat treatment and shape setting to establish the material's transformation temperatures and memorized shape

- Surface finishing techniques such as electropolishing to improve corrosion resistance and biocompatibility

Each step in the manufacturing process is carefully controlled to produce ASTM F2063 shape memory nitinol rods with consistent and reliable properties.

Quality Control and Testing

Ensuring the quality and performance of ASTM F2063 nitinol rods is critical, especially for medical applications. Manufacturers employ various testing methods to verify the material's properties and compliance with standards. These tests may include:

- Differential scanning calorimetry (DSC) to determine transformation temperatures

- Tensile testing to evaluate mechanical properties and superelastic behavior

- Fatigue testing to assess long-term performance and durability

- Chemical analysis to confirm composition and purity

- Microstructural examination to verify grain size and phase distribution

Rigorous quality control ensures that ASTM F2063 nitinol rods meet the stringent requirements for their intended applications, providing reliable and consistent performance in critical devices and components.

Conclusion

ASTM F2063 shape memory nitinol rods represent a remarkable class of materials with unique properties that enable innovative solutions across various industries. Their shape memory effect, superelasticity, and biocompatibility have revolutionized medical device design and continue to inspire new applications. As research and manufacturing techniques advance, we can expect even more exciting developments in the field of nitinol technology. If you want to get more information about this product, you can contact us at baojihanz-niti@hanztech.cn.

References

1. Duerig, T. W., & Pelton, A. R. (2018). Materials properties handbook: titanium alloys. ASM international.

2. Pelton, A. R., Stockel, D., & Duerig, T. W. (2000). Medical uses of nitinol. Materials Science Forum, 327, 63-70.

3. Otsuka, K., & Wayman, C. M. (Eds.). (1999). Shape memory materials. Cambridge university press.

4. Yoneyama, T., & Miyazaki, S. (Eds.). (2008). Shape memory alloys for biomedical applications. Elsevier.

5. Lagoudas, D. C. (Ed.). (2008). Shape memory alloys: modeling and engineering applications. Springer Science & Business Media.

6. Robertson, S. W., Pelton, A. R., & Ritchie, R. O. (2012). Mechanical fatigue and fracture of Nitinol. International Materials Reviews, 57(1), 1-36.