What are the properties of shape memory nitinol foil?

2024-10-18 22:38:50

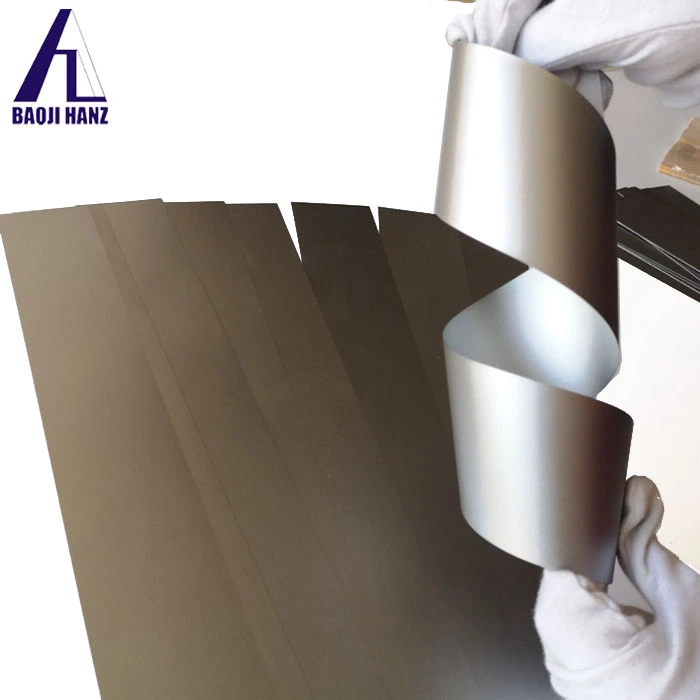

Shape memory nitinol foil is a remarkable material that has captivated the attention of engineers, scientists, and innovators across various industries. This unique alloy, composed of nickel and titanium, exhibits extraordinary properties that set it apart from conventional metals. In this comprehensive exploration, we'll delve into the fascinating world of shape memory nitinol foil, uncovering its distinctive characteristics, diverse applications, and the science behind its remarkable behavior. From its ability to "remember" and return to its original shape after deformation to its superelastic nature, we'll unravel the mysteries of this extraordinary material and its potential to revolutionize numerous fields.

The Fundamentals of Shape Memory Nitinol Foil

Composition and Structure

Shape memory nitinol foil is composed of nearly equal atomic percentages of nickel and titanium. This precise composition gives rise to its unique crystal structure, which undergoes a reversible phase transformation between austenite and martensite. The austenite phase exists at higher temperatures and has a cubic crystal structure, while the martensite phase occurs at lower temperatures and possesses a more complex, twinned structure.

Shape Memory Effect

The hallmark property of shape memory nitinol foil is its ability to "remember" and return to a predetermined shape when heated above a specific transformation temperature. This phenomenon, known as the shape memory effect, occurs due to the reversible phase transformation between martensite and austenite. When the foil is deformed in its martensitic state and subsequently heated, it reverts to its austenitic structure, recovering its original shape with remarkable precision.

Superelasticity

Another remarkable property of shape memory nitinol foil is its superelasticity, also known as pseudoelasticity. This characteristic allows the material to undergo large deformations without permanent plastic deformation. When stress is applied to the foil in its austenitic state, it transforms to stress-induced martensite, accommodating the strain. Upon removal of the stress, the material immediately reverts to its austenitic structure, recovering its original shape without the need for heating.

Unique Properties of Shape Memory Nitinol Foil

Thermal and Mechanical Memory

Shape memory nitinol foil boasts an extraordinary ability to remember both thermal and mechanical inputs, which is a defining characteristic of this advanced material. This dual memory capability enables the foil to be programmed to respond predictably to specific temperature changes or mechanical stresses. When heated above a certain transformation temperature, the material can revert to its original shape, while it can also undergo deformation under applied stress and subsequently return to its programmed form once the stress is removed. This unique property makes nitinol invaluable in applications that require precise and repeatable actuation, such as in medical devices, robotics, and aerospace components, where reliability and accuracy are paramount.

High Fatigue Resistance

Unlike many conventional metals, shape memory nitinol foil exhibits exceptional fatigue resistance, a property that significantly enhances its usability in demanding applications. This remarkable resilience stems from its unique microstructure and the reversible nature of its phase transformations, which allow the material to endure substantial stress without permanent deformation. As a result, nitinol can undergo millions of loading cycles while maintaining its integrity and performance. This durability makes it particularly suitable for applications involving repetitive motions or frequent shape changes, such as in medical devices like stents and catheters, as well as in robotics and aerospace systems, where reliability under continuous operation is crucial.

Biocompatibility

Shape memory nitinol foil is a popular choice for numerous applications in bioengineering and medicine due to its excellent biocompatibility. Because of its inherent resistance to corrosion in bodily fluids, it maintains long-term stability and functionality, significantly lowering the risk of adverse reactions in the body. Additionally, nitinol's ability to imitate the mechanical properties of human tissues makes it easier for implantable devices to seamlessly integrate with biological systems. Because of its adaptability, it is widely used in a variety of applications, such as stents, orthopedic implants, surgical instruments, and dental devices, where optimal compatibility and performance are essential for patient safety and successful treatment outcomes.

Applications and Innovations

Medical Devices

The unique properties of shape memory nitinol foil have revolutionized the field of medical devices. Its superelasticity and biocompatibility make it ideal for stents, which can be compressed for minimally invasive insertion and then expand to their predetermined shape once in place. Other applications include orthodontic archwires, surgical instruments, and implantable devices that adapt to the body's anatomy.

Aerospace and Automotive Industries

In aerospace and automotive applications, shape memory nitinol foil finds use in actuators, vibration damping systems, and adaptive structures. Its ability to change shape in response to temperature or stress allows for the creation of smart components that can adjust their configuration to optimize performance under varying conditions. This property is particularly valuable in developing morphing aircraft structures and self-adjusting automotive components.

Consumer Electronics

The electronics industry has embraced shape memory nitinol foil for its unique properties. It is used in thermal actuators for circuit breakers, antenna deployment mechanisms in mobile devices, and even in haptic feedback systems. The material's ability to respond to electrical currents through resistive heating makes it an excellent choice for creating compact, reliable actuators in small electronic devices.

Conclusion

Shape memory nitinol foil stands as a testament to the marvels of materials science, offering a unique combination of properties that continue to inspire innovation across diverse fields. Its shape memory effect, superelasticity, and biocompatibility open up a world of possibilities for engineers and designers seeking to create smarter, more adaptive technologies. As research in this field progresses, we can anticipate even more groundbreaking applications that harness the extraordinary capabilities of this remarkable material. If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1. Otsuka, K., & Wayman, C. M. (Eds.). (1998). Shape Memory Materials. Cambridge University Press.

2. Lagoudas, D. C. (Ed.). (2008). Shape Memory Alloys: Modeling and Engineering Applications. Springer Science & Business Media.

3. Duerig, T., Pelton, A., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273, 149-160.

4. Jani, J. M., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

5. Morgan, N. B. (2004). Medical shape memory alloy applications—the market and its products. Materials Science and Engineering: A, 378(1-2), 16-23.

6. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design (1980-2015), 56, 1078-1113.