What are the typical applications of Nitinol sheets?

2024-11-23 18:51:17

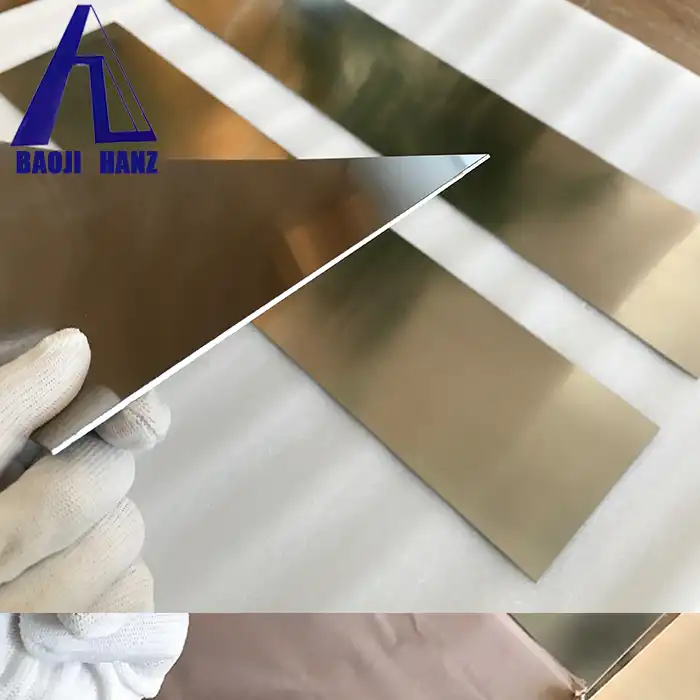

Nitinol sheets, composed of nickel titanium shape alloy sheet, have revolutionized various industries due to their unique properties. These remarkable materials exhibit superelasticity and shape memory effects, making them invaluable in a wide range of applications. Nitinol sheets are typically used in medical devices, aerospace engineering, automotive systems, and consumer electronics. In the medical field, they're utilized for creating stents, guidewires, and orthodontic archwires. Aerospace engineers incorporate Nitinol sheets into aircraft structures for noise reduction and vibration damping. Automotive manufacturers use them in adaptive headlights and climate control systems. Consumer electronics benefit from Nitinol's properties in smartphone antennas and laptop hinges. The versatility of Nitinol sheets extends to robotics, where they're employed in actuators and sensors. Additionally, these innovative materials find applications in fashion, sports equipment, and even architecture, showcasing their adaptability across diverse sectors.

Medical Applications of Nitinol Sheets

Cardiovascular Devices

Nitinol sheets play a crucial role in the development of cardiovascular devices. Their superelastic properties make them ideal for creating self-expanding stents, which are used to treat blocked arteries. These stents can be compressed into a small diameter for insertion and then expand to their original shape once in place, providing support to the vessel walls. Nitinol's biocompatibility and resistance to corrosion in bodily fluids further enhance its suitability for long-term implantation.

Orthopedic Implants

In orthopedics, nickel titanium shape alloy sheets are utilized to manufacture bone plates, spinal rods, and other implants. The shape memory effect allows these devices to change form in response to body temperature, enabling minimally invasive surgical procedures. For instance, a Nitinol bone plate can be inserted in a compact form and then expand to its functional shape once inside the body, reducing surgical trauma and improving patient recovery times.

Dental Applications

The dental industry has embraced Nitinol sheets for creating orthodontic archwires and endodontic files. Orthodontic archwires made from Nitinol apply consistent, gentle forces over extended periods, leading to more efficient tooth movement. In endodontics, Nitinol files can navigate curved root canals more effectively than traditional stainless steel instruments, reducing the risk of canal perforation and improving treatment outcomes.

Aerospace and Automotive Applications

Smart Structures in Aircraft

Aerospace engineers have found innovative ways to leverage the unique properties of Nitinol sheets to create smart structures in aircraft. Nitinol, a shape memory alloy, possesses the remarkable ability to change shape in response to temperature variations. This characteristic has been exploited in the design of aircraft wings, where Nitinol sheets are integrated to allow for dynamic shape changes during flight. These adaptable wing structures can optimize aerodynamic performance under varying flight conditions, such as different speeds, altitudes, or atmospheric conditions.The shape memory effect of Nitinol also makes it valuable for reducing noise and improving passenger comfort within aircraft cabins.By incorporating Nitinol-based components into the cabin design, aerospace engineers can develop innovative solutions to address the challenges of noise and vibration control, further enhancing the overall comfort and well-being of aircraft passengers.

Thermal Management Systems

Nickel titanium shape alloy sheets have found widespread applications in thermal management systems across both the aerospace and automotive industries. The shape memory properties of Nitinol allow for the creation of temperature-responsive louvers and vents that can automatically adjust to regulate heat flow. This feature is particularly valuable in managing engine temperatures and maintaining optimal operating conditions in various vehicle components.In aerospace applications, Nitinol-based thermal management systems play a crucial role in ensuring the efficient cooling and heating of aircraft subsystems and components. The self-regulating nature of Nitinol-actuated louvers and vents enables the system to adapt to changing thermal demands, ensuring that critical components are maintained within their optimal operating temperature ranges. This intelligent thermal management helps to optimize aircraft performance, reduce fuel consumption, and enhance overall system reliability.

Safety Mechanisms

Nitinol's exceptional properties, including superelasticity and shape memory effects, have been harnessed in the development of advanced safety mechanisms for both aircraft and automobiles. In the aerospace industry, Nitinol-based actuators have found applications in emergency systems, such as deployable air brakes or landing gear components.The shape memory and superelastic characteristics of Nitinol allow for the creation of highly reliable and responsive actuators that can rapidly deploy these critical safety systems in the event of an emergency. The ability of Nitinol to recover its original shape after deformation ensures the consistent and reliable operation of these safety mechanisms, enhancing the overall safety and integrity of the aircraft.In the automotive industry, Nitinol sheets have contributed to the development of advanced crumple zones and impact-absorbing structures, designed to enhance passenger safety during collisions. The unique properties of Nitinol enable the creation of crush structures that can absorb and dissipate the energy of an impact, reducing the risk of serious injury to occupants.

Consumer Electronics and Robotics Applications

Flexible Displays and Antennas

The consumer electronics industry has found innovative uses for Nitinol sheets in the development of flexible displays and antennas. The material's superelastic properties allow for the creation of bendable screens that can withstand repeated folding and unfolding without damage. In smartphones and other mobile devices, Nitinol-based antennas can be designed to deploy when needed and retract when not in use, optimizing signal reception while maintaining sleek device profiles.

Haptic Feedback Systems

Nitinol sheets are increasingly being used in haptic feedback systems for touchscreens and gaming controllers. Their ability to rapidly change shape in response to electrical stimuli allows for the creation of more realistic and nuanced tactile sensations. This enhances user interaction with devices, providing a more immersive experience in gaming and improving accessibility features for visually impaired users.

Robotic Actuators and Sensors

In the field of robotics, nickel titanium shape alloy sheets are utilized to create compact and efficient actuators and sensors. The material's shape memory effect enables the development of artificial muscles that can produce smooth, lifelike movements in robotic limbs. Nitinol-based sensors can detect minute changes in temperature or pressure, making them valuable in applications ranging from industrial automation to humanoid robotics.

Conclusion

Nickel titanium shape alloy sheets, with their remarkable shape memory and superelastic properties, have found applications across a diverse range of industries. From life-saving medical devices to cutting-edge aerospace technologies and innovative consumer electronics, the versatility of this nickel titanium alloy continues to drive innovation and improve product performance in numerous fields. If you want to get more information about this product, you can contact us at baojihanz-niti@hanztech.cn.

References

1. Pelton, A. R., et al. "Medical Uses of Nitinol." Materials Science Forum, vol. 327-328, 2000, pp. 63-70.

2. Jani, J. M., et al. "A review of shape memory alloy research, applications and opportunities." Materials & Design, vol. 56, 2014, pp. 1078-1113.

3. Mohd Jani, J., et al. "A review of shape memory alloy research, applications and opportunities." Materials & Design, vol. 56, 2014, pp. 1078-1113.

4. Hartl, D. J., and D. C. Lagoudas. "Aerospace applications of shape memory alloys." Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, vol. 221, no. 4, 2007, pp. 535-552.

5. Sun, L., et al. "Stimulus-responsive shape memory materials: A review." Materials & Design, vol. 33, 2012, pp. 577-640.

6. Barbarino, S., et al. "A review on shape memory alloys with applications to morphing aircraft." Smart Materials and Structures, vol. 23, no. 6, 2014, p. 063001.