What industries use shape memory nitinol foil?

2024-10-18 22:37:13

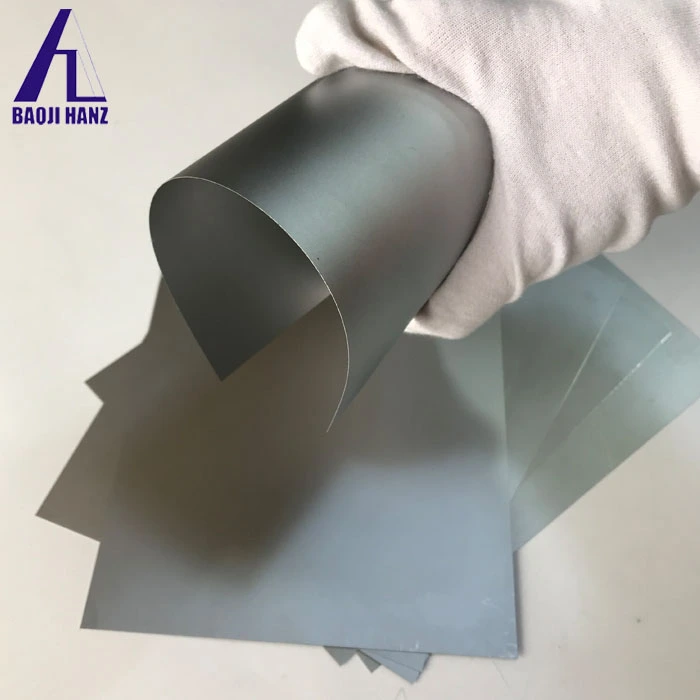

Shape memory nitinol foil is a remarkable material that has revolutionized numerous industries due to its unique properties. This innovative alloy, composed of nickel and titanium, possesses the extraordinary ability to "remember" and return to its original shape when subjected to specific temperature changes. Its superelastic nature, combined with excellent biocompatibility and corrosion resistance, has made nitinol foil an indispensable component in various applications across multiple sectors. In this comprehensive exploration, we'll delve into the diverse industries that harness the power of nitinol foil, examining its transformative impact and the innovative solutions it enables.

Medical and Healthcare Applications

Cardiovascular Devices

Shape foil has found extensive use in the development of cardiovascular devices. Its superelastic properties make it ideal for creating self-expanding stents, which can be compressed into a small diameter for minimally invasive insertion and then expand to their predetermined shape once deployed in blood vessels. These stents help to keep arteries open and improve blood flow in patients with cardiovascular diseases. Additionally, nitinol foil is utilized in the fabrication of heart valve frames, providing a flexible yet durable structure that can withstand the constant movement of the heart.

Orthopedic Implants

In orthopedic applications, shape memory nitinol foil plays a crucial role in developing advanced implants and devices. Its unique properties allow for the creation of bone plates and screws that can adapt to the natural curvature of bones, providing better fixation and promoting faster healing. Nitinol foil is also used in spinal implants, where its shape memory characteristics enable the development of dynamic stabilization systems that can maintain flexibility while supporting the spine. These innovations have significantly improved patient outcomes and reduced recovery times in orthopedic surgeries.

Dental Instruments

The dental industry has embraced nitinol foil for its exceptional properties in creating advanced instruments and appliances. Orthodontic archwires made from nitinol foil provide consistent, gentle forces for tooth movement, resulting in more comfortable and efficient treatments. The material's superelasticity allows for the development of endodontic files that can navigate complex root canal systems with reduced risk of breakage. Moreover, nitinol foil is used in the fabrication of dental implants, where its biocompatibility and shape memory properties contribute to improved osseointegration and long-term stability.

Aerospace and Aviation Industry

Aircraft Actuation Systems

The aerospace industry is using nitinol foil to create innovative, lightweight actuation systems that replace traditional hydraulic or pneumatic components. These actuators enhance wing morphing for improved aerodynamics, benefiting from high fatigue resistance and extreme temperature performance.

Vibration Damping

Shape memory nitinol foil has proven invaluable in addressing vibration issues in aerospace applications. Its superelastic properties allow for the creation of damping systems that can absorb and dissipate energy effectively. These systems are employed in aircraft engines, where they help reduce vibration-induced fatigue and extend component life. Additionally, nitinol foil-based dampers are used in satellite structures to mitigate the effects of launch vibrations and thermal cycling in space, ensuring the longevity and reliability of sensitive equipment.

Thermal Management

Shape foil is used in aerospace thermal management systems for passive temperature control devices that require no external power. It helps maintain optimal temperatures in satellites and is employed in deployable radiators and sunshields for heat dissipation and solar protection.

Consumer Electronics and Robotics

Haptic Feedback Devices

In the realm of consumer electronics, nitinol foil has enabled the development of advanced haptic feedback systems. Its rapid response to electrical stimuli allows for the creation of tactile sensations that enhance user experiences in touchscreens, gaming controllers, and virtual reality interfaces. The material's ability to generate precise, localized movements has revolutionized the way we interact with electronic devices, providing more immersive and intuitive user interfaces.

Microactuators for Robotics

The robotics industry has leveraged shape memory nitinol foil to create compact and efficient microactuators. These actuators utilize the material's shape memory effect to produce controlled movements in small-scale robotic systems. Nitinol foil-based actuators offer advantages such as high power-to-weight ratios, silent operation, and the ability to function in confined spaces. They are employed in various applications, including robotic grippers, artificial muscles for humanoid robots, and miniature robotic surgical instruments.

Wearable Technology

Shape foil has found its way into the burgeoning field of wearable technology. Its flexibility and shape memory properties make it ideal for creating adaptive and responsive wearable devices. Nitinol foil is used in the development of smart textiles that can change shape or texture in response to environmental conditions or user inputs. It is also employed in the fabrication of flexible circuit boards and antennas for wearable electronics, enabling the creation of more comfortable and durable devices that can conform to the human body.

Conclusion

Shape memory nitinol foil has proven to be a versatile and transformative material across numerous industries. From its critical role in medical devices to its innovative applications in aerospace and consumer electronics, nitinol foil continues to push the boundaries of what is possible in material science and engineering. As research and development in this field progress, we can expect to see even more groundbreaking applications that harness the unique properties of this remarkable alloy.If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1. Duerig, T. W., & Pelton, A. R. (2018). "Materials properties handbook: titanium alloys." ASM International.

2. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). "A review of shape memory alloy research, applications and opportunities." Materials & Design, 56, 1078-1113.

3. Elahinia, M. H., Hashemi, M., Tabesh, M., & Bhaduri, S. B. (2012). "Manufacturing and processing of NiTi implants: A review." Progress in Materials Science, 57(5), 911-946.

4. Hartl, D. J., & Lagoudas, D. C. (2007). "Aerospace applications of shape memory alloys." Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, 221(4), 535-552.

5. Sun, L., Huang, W. M., Ding, Z., Zhao, Y., Wang, C. C., Purnawali, H., & Tang, C. (2012). "Stimulus-responsive shape memory materials: a review." Materials & Design, 33, 577-640.

6. Barbarino, S., Flores, E. I. S., Ajaj, R. M., Dayyani, I., & Friswell, M. I. (2014). "A review on shape memory alloys with applications to morphing aircraft." Smart Materials and Structures, 23(6), 063001.