What industries use shape memory nitinol rods?

2024-10-31 21:34:56

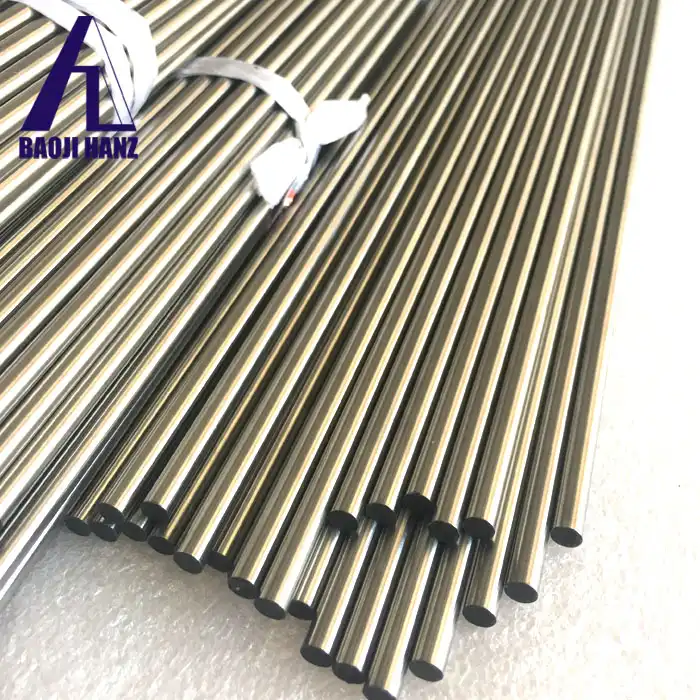

Shape memory nitinol rods have revolutionized numerous industries due to their unique properties of shape memory and superelasticity. These remarkable alloys, composed of nickel and titanium, possess the ability to return to a predetermined shape when subjected to specific temperatures or stress conditions. This blog explores the diverse applications of nitinol rods across various sectors, highlighting how their extraordinary characteristics have transformed product designs and functionalities. From medical devices to aerospace engineering, we'll delve into the industries that harness the power of these innovative materials to create cutting-edge solutions and push the boundaries of technological advancement.

Medical Industry: Pioneering Applications of Shape Memory Nitinol Rods

Cardiovascular Devices: Enhancing Minimally Invasive Procedures

The medical industry has widely adopted nitinol rods, particularly in cardiovascular devices, transforming stent design and functionality. Nitinol's superelasticity allows stents to be compressed for catheter insertion and expand once deployed, enhancing procedural efficiency and patient outcomes. Additionally, nitinol is used in vena cava filters, preventing blood clots from reaching the lungs while adapting to the body’s movements, making it ideal for these critical applications.

Orthopedic Implants: Adapting to the Body's Needs

In orthopedics, nitinol rods have revolutionized bone fixation and repair. Surgeons now use nitinol-based staples and plates that can be inserted at room temperature and activated by body heat for a secure fit, reducing surgical time and enhancing healing. Nitinol rods are also employed in spinal correction devices, allowing gradual adjustment of spinal deformities, minimizing invasive procedures, and ensuring a more comfortable experience for patients in long-term treatment.

Dental Applications: Smarter Orthodontic Solutions

The dental industry has also harnessed the potential of shape memory nitinol rods, particularly in orthodontics. Nitinol archwires have become a game-changer in braces technology. These wires exert a constant, gentle force on teeth over an extended period, reducing the need for frequent adjustments and shortening overall treatment times. Furthermore, nitinol's biocompatibility and resistance to corrosion make it an excellent choice for dental implants and other oral surgical devices. Its ability to withstand the challenging environment of the oral cavity while maintaining its structural integrity has led to more durable and effective dental solutions.

Aerospace and Aviation: Elevating Performance with Shape Memory Nitinol Rods

Aircraft Structural Components: Enhancing Efficiency and Safety

The aerospace industry has innovatively integrated nitinol rods into aircraft design. A key application is in variable geometry chevrons on engine nacelles, which change shape based on flight conditions to optimize engine performance and reduce noise during takeoff and landing. Additionally, nitinol rods are used in wing components to create morphing structures that adapt to different flight conditions, enhancing aerodynamic efficiency and leading to fuel savings and improved overall performance.

Space Exploration: Compact and Deployable Structures

In space exploration, nitinol rods are essential for creating compact, deployable structures. Satellite antennas and solar panels can fold into a small volume for launch and expand fully in orbit, maximizing payload capacity and ensuring successful deployment. Additionally, nitinol-based actuators are utilized in robotic arms and instrument deployment systems, as the material's reliability in extreme temperatures and high strength-to-weight ratio make it ideal for space applications where weight is critical.

Aviation Safety: Smart Fasteners and De-icing Systems

Shape memory nitinol rods have found applications in aviation safety systems as well. Smart fasteners made from nitinol can be designed to maintain a tight grip under normal conditions but release when subjected to specific stresses, potentially preventing catastrophic failures in emergency situations.Additionally, nitinol-based de-icing systems are being developed for aircraft wings. These systems utilize the material's shape-changing properties to create surfaces that can physically shed ice accumulation, offering a more energy-efficient alternative to traditional heating methods.

Consumer Electronics and Robotics: Integrating Shape Memory Nitinol Rods for Smart Design

Mobile Devices: Enhancing Durability and Functionality

The consumer electronics industry is exploring nitinol rods for mobile device design. One application is in impact-resistant smartphone cases, which use nitinol components to absorb and distribute shock, protecting devices from drops. Additionally, nitinol supports the development of foldable or rollable displays for smartphones and tablets, thanks to its superelastic properties that allow repeated bending without fatigue, paving the way for flexible and durable screens that could transform mobile device form factors.

Robotics: Enabling Precision Movements and Adaptability

In robotics, shape memory nitinol rods are revolutionizing actuator design by enabling smooth, controlled movements with a high power-to-weight ratio. This makes them suitable for various applications, including industrial robots and biomimetic designs. Soft robotics has particularly benefited from nitinol’s flexibility, allowing the development of adaptable robotic structures that can navigate complex environments and safely interact with humans. From underwater exploration robots to assistive medical devices, nitinol is driving the creation of versatile and responsive robotic systems.

Wearable Technology: Comfort and Functionality Combined

The wearable technology sector has adopted nitinol rods to enhance comfort and functionality. Nitinol frames in smart glasses adapt to different face shapes for a personalized fit, while nitinol components in smartwatches allow for adjustable bands that retain shape over time. Additionally, these rods are being explored in smart textiles, enabling garments to respond to temperature changes for improved insulation and ventilation, enhancing comfort in diverse environments.

Conclusion

Shape nitinol rods have proven to be versatile and transformative materials across a wide range of industries. From revolutionizing medical devices to enhancing aerospace technologies and enabling innovative consumer electronics, the unique properties of these alloys continue to drive advancements and inspire new applications. As research and development in this field progress, we can expect to see even more exciting and groundbreaking uses for shape memory nitinol rods in the future.If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1. Duerig, T., Pelton, A., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273-275, 149-160.

2. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

3. Lagoudas, D. C. (Ed.). (2008). Shape memory alloys: modeling and engineering applications. Springer Science & Business Media.

4. Hartl, D. J., & Lagoudas, D. C. (2007). Aerospace applications of shape memory alloys. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, 221(4), 535-552.

5. Morgan, N. B. (2004). Medical shape memory alloy applications—the market and its products. Materials Science and Engineering: A, 378(1-2), 16-23.

6. Sun, L., Huang, W. M., Ding, Z., Zhao, Y., Wang, C. C., Purnawali, H., & Tang, C. (2012). Stimulus-responsive shape memory materials: a review. Materials & Design, 33, 577-640.