What is a shape memory nitinol rod?

2024-11-07 21:07:59

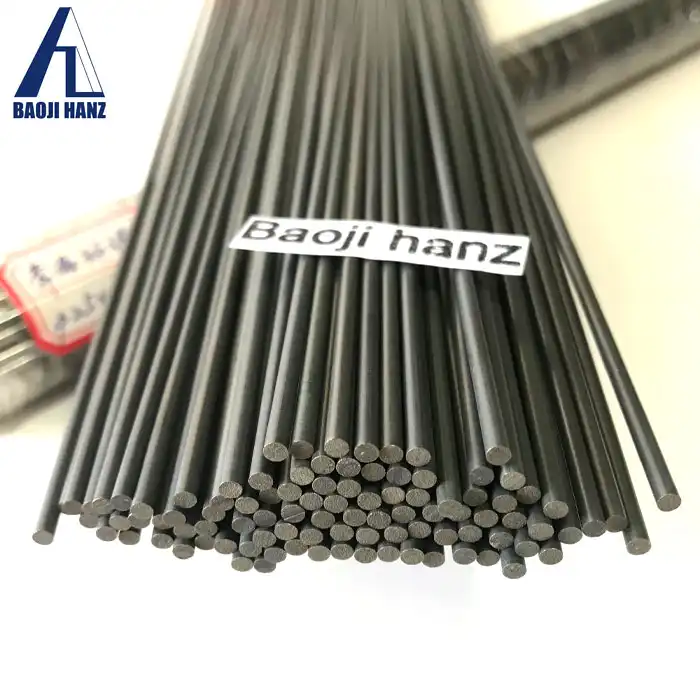

Shape memory nitinol rods are revolutionary materials that have captured the attention of engineers, scientists, and innovators across various industries. These remarkable rods, composed of nickel and titanium alloy, possess the unique ability to "remember" and return to their original shape after deformation when exposed to specific temperatures. This blog delves into the fascinating world of nitinol rods, exploring their properties, applications, and the science behind their behavior. Whether you're a materials engineer, a medical device designer, or simply curious about cutting-edge technologies, this comprehensive guide will provide valuable insights into these transformative materials.

Understanding Shape Memory Nitinol Rods

Composition and Structure of Nitinol

Nitinol, an equiatomic nickel-titanium alloy, exhibits remarkable properties due to its unique composition. It undergoes a phase transformation between two states: austenite and martensite, which is essential for its shape memory effect and superelasticity. In the high-temperature austenite phase, it has a cubic crystal structure, while cooling induces a transition to martensite with a complex twinned structure. This thermoelastic martensitic transformation occurs without changing the material's macroscopic shape.

The Shape Memory Effect Explained

The shape memory effect is the key feature of shape memory nitinol rods. When deformed in the low-temperature martensite phase, these rods hold their new shape. However, heating them to their transformation temperature restores their original shape, a process that can be repeated many times without damaging the material. This behavior stems from the reversible transformation between austenite and martensite. The transformation temperature can be adjusted by modifying the nickel-titanium ratio or through heat treatments, allowing for application-specific customization.

Superelasticity: A Related Phenomenon

Nitinol also exhibits superelasticity, or pseudoelasticity, enabling it to undergo significant deformations and return to its original shape upon stress removal, without temperature changes. This occurs when nitinol is in its austenite phase and experiences stress, prompting a transformation to martensite that accommodates large strains. When the stress is released, it reverts to austenite, regaining its original shape. Such properties make nitinol rods ideal for applications requiring flexibility and resilience.

Manufacturing and Processing of Shape Memory Nitinol Rods

Melting and Casting Techniques

The production of shape memory nitinol rods starts with the careful melting and alloying of nickel and titanium, typically using vacuum induction melting to ensure high purity and precise composition control. The molten alloy is cast into ingots, which become the basis for further processing. Advanced techniques like vacuum arc remelting may enhance the microstructure and remove impurities. The melting and casting processes are crucial in defining the final properties of the nitinol rods, including their transformation temperatures and mechanical characteristics.

Hot Working and Cold Drawing

The nitinol ingots undergo a series of hot working processes to break down the as-cast structure and improve homogeneity. This may include forging, rolling, or extrusion operations performed at elevated temperatures. The hot-worked material is then subjected to cold drawing processes to reduce its diameter and achieve the desired rod dimensions.Cold drawing is a crucial step in the production of nitinol rods, as it imparts significant work hardening and influences the material's final properties. Multiple drawing passes may be required, often with intermediate annealing treatments to relieve internal stresses and maintain workability.

Heat Treatment and Shape Setting

Heat treatment is a crucial step in manufacturing nitinol rods, as it establishes the "remembered" shape and fine-tunes transformation temperatures. Specific parameters like temperature and duration are meticulously controlled to achieve the desired properties. Shape setting involves constraining the rod in the desired configuration and heating it to between 400°C and 550°C, aligning the crystal structure to establish the memory shape. This process is completed with subsequent quenching or controlled cooling.

Applications of Shape Memory Nitinol Rods

Medical Devices and Implants

The unique properties and biocompatibility of shape memory nitinol rods have transformed medical devices significantly. In cardiovascular applications, nitinol stents can be compressed for minimally invasive insertion and then expand to their original shape once deployed in blood vessels. This self-expanding capability minimizes the risk of restenosis and enhances patient outcomes. Additionally, nitinol orthodontic archwires provide consistent, gentle forces for tooth movement over extended periods, utilizing their superelastic characteristics. In orthopedics, nitinol rods are utilized in spine correction devices and fracture fixation implants, where maintaining a constant force despite displacement changes is particularly advantageous.

Aerospace and Automotive Industries

In aerospace engineering, nitinol rods have various applications, notably in vibration damping systems, where their superelastic properties help absorb mechanical vibrations. They are also used in aircraft hydraulic couplings, providing leak-free, temperature-activated seals that withstand extreme conditions. In the automotive industry, nitinol rods serve as actuators for systems like climate control vents and adaptive headlights. Their compact size and ability to generate substantial forces make them ideal for these uses. Furthermore, nitinol-based impact absorption systems are being developed to improve vehicle safety.

Consumer Electronics and Robotics

The trend of miniaturization in consumer electronics has led to increased utilization of nitinol rods in micro-actuators and switches. These components respond to electrical heating, allowing precise movements in compact devices like smartphones and wearables. In robotics, nitinol rods are explored for artificial muscles and flexible manipulators. Their capacity to mimic biological muscle behavior, along with a high strength-to-weight ratio, positions them as promising candidates for soft robotics. Researchers are also examining nitinol-based actuators for haptic feedback systems in virtual reality interfaces.

Conclusion

Shape memory nitinol rods represent a remarkable advancement in materials science, offering unique capabilities that span various industries. Their ability to remember shapes, coupled with superelasticity, opens up innovative possibilities in medical, aerospace, automotive, and consumer applications. As research continues, we can expect to see even more creative uses for these versatile materials in the future. If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1. Otsuka, K., & Wayman, C. M. (Eds.). (1998). Shape Memory Materials. Cambridge University Press.

2. Duerig, T. W., Melton, K. N., Stöckel, D., & Wayman, C. M. (Eds.). (2013). Engineering Aspects of Shape Memory Alloys. Butterworth-Heinemann.

3. Lagoudas, D. C. (Ed.). (2008). Shape Memory Alloys: Modeling and Engineering Applications. Springer Science & Business Media.

4. Jani, J. M., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

5. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

6. Sun, L., Huang, W. M., Ding, Z., Zhao, Y., Wang, C. C., Purnawali, H., & Tang, C. (2012). Stimulus-responsive shape memory materials: A review. Materials & Design, 33, 577-640.