What is shape memory nitinol and how does it work?

2025-02-10 22:14:43

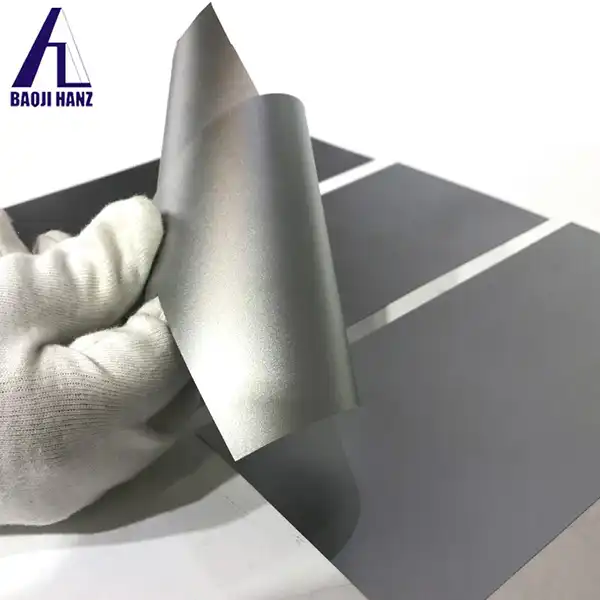

Shape memory nitinol is a remarkable alloy that possesses unique properties, making it invaluable in various industries. This blog explores the fascinating world of shape memory nitinol, delving into its composition, properties, and applications. We'll uncover the science behind its shape memory effect and superelasticity, shedding light on how these characteristics make nitinol an indispensable material in fields ranging from medicine to aerospace. By understanding the intricacies of shape memory nitinol foil and its behavior, we can appreciate its versatility and potential for innovation in countless applications.

The Composition and Properties of Shape Memory Nitinol

The Chemical Makeup of Nitinol

Nitinol is an equiatomic alloy composed of nickel and titanium. The name "Nitinol" is derived from its constituents: Nickel Titanium Naval Ordnance Laboratory. This unique composition gives nitinol its exceptional properties, setting it apart from conventional metals. The precise balance of nickel and titanium atoms in the crystal structure is crucial for the alloy's shape memory and superelastic behaviors.

Crystal Structure and Phase Transformations

The remarkable properties of shape memory nitinol stem from its ability to undergo reversible phase transformations. At higher temperatures, nitinol exists in an austenite phase with a cubic crystal structure. When cooled, it transforms into a martensite phase with a monoclinic crystal structure. This phase change is the key to nitinol's shape memory effect. The transformation temperature can be fine-tuned by adjusting the ratio of nickel to titanium in the alloy, allowing for customization based on specific application requirements.

Unique Mechanical Characteristics

Shape memory nitinol exhibits extraordinary mechanical properties. Its superelasticity allows it to undergo large deformations and return to its original shape upon unloading, making it ideal for applications requiring flexibility and resilience. Additionally, nitinol boasts high fatigue resistance, corrosion resistance, and biocompatibility, further expanding its potential uses across various industries. These properties make shape memory nitinol foil particularly valuable in applications where traditional materials fall short.

The Shape Memory Effect: Mechanism and Applications

Understanding the Shape Memory Phenomenon

The shape memory effect is a fascinating property that allows nitinol to "remember" and return to a predetermined shape when heated. This behavior occurs due to the reversible martensitic transformation in the alloy's crystal structure. When deformed in its low-temperature martensite phase, nitinol can be easily shaped. Upon heating above its transformation temperature, it reverts to its austenite phase, recovering its original shape with considerable force. This unique ability has revolutionized numerous fields, from medical devices to aerospace technologies.

One-Way vs. Two-Way Shape Memory

Shape memory nitinol can exhibit either one-way or two-way shape memory effects. In one-way shape memory, the material remembers only its high-temperature austenite shape and must be mechanically deformed to change its shape at lower temperatures. Two-way shape memory, on the other hand, allows the material to remember both its high-temperature and low-temperature shapes, cycling between them with temperature changes. This behavior is achieved through specific training processes and opens up even more possibilities for smart material applications.

Practical Applications of Shape Memory Nitinol

The shape memory effect of nitinol has found numerous practical applications across various industries. In medicine, it's used to create self-expanding stents that can be compressed for insertion and then expand to their predetermined shape once inside the body. Orthodontic archwires made from nitinol provide constant, gentle force for tooth alignment. In aerospace, shape memory nitinol actuators are used for deployment mechanisms in satellites and spacecraft. The automotive industry utilizes nitinol for thermal actuators in engine management systems. These applications showcase the versatility and potential of shape memory nitinol foil in solving complex engineering challenges.

Superelasticity: The Other Remarkable Property of Nitinol

The Science Behind Superelasticity

Superelasticity, also known as pseudoelasticity, is another extraordinary property of nitinol that complements its shape memory effect. This phenomenon allows nitinol to undergo large deformations and immediately return to its original shape upon unloading, without the need for temperature change. Superelasticity occurs when nitinol is above its austenite finish temperature. When stress is applied, the austenite phase transforms into stress-induced martensite, allowing for significant strain. Upon removal of the stress, the martensite reverts to austenite, and the material recovers its shape. This behavior enables nitinol to exhibit elastic strains up to 20 times greater than those of conventional metals.

Comparing Superelasticity to Traditional Elasticity

The superelasticity of nitinol differs significantly from the elasticity of conventional materials. While traditional metals typically have elastic strains limited to less than 1%, superelastic nitinol can recover strains of up to 8% without permanent deformation. This exceptional property allows for the design of devices that can undergo large deformations without failure or loss of functionality. The stress-strain curve of superelastic nitinol also exhibits a unique plateau region, where large strains can be accommodated with minimal increase in stress. This behavior is particularly advantageous in applications requiring constant force over a range of displacements.

Applications Leveraging Nitinol's Superelasticity

The superelastic properties of nitinol have led to innovative applications across various fields. In medicine, superelastic nitinol is used to create guidewires for minimally invasive procedures, allowing for easy navigation through tortuous blood vessels. Cardiovascular stents made from superelastic nitinol can be compressed for insertion and then expand to support vessel walls. In dentistry, nitinol files are used for root canal procedures due to their flexibility and resistance to breakage. The eyewear industry utilizes superelastic nitinol for flexible frames that can withstand significant deformation without breaking. These applications demonstrate how the unique properties of shape memory nitinol foil continue to push the boundaries of material science and engineering.

Conclusion

Shape memory nitinol is a remarkable material that continues to revolutionize various industries with its unique properties. Its ability to remember shapes and exhibit superelasticity opens up a world of possibilities for innovative applications. As research in this field progresses, we can expect to see even more groundbreaking uses for shape memory nitinol foil in the future. If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1. Otsuka, K., & Wayman, C. M. (Eds.). (1999). Shape memory materials. Cambridge University Press.

2. Duerig, T., Pelton, A., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273-275, 149-160.

3. Lagoudas, D. C. (Ed.). (2008). Shape memory alloys: modeling and engineering applications. Springer Science & Business Media.

4. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

5. Sun, L., Huang, W. M., Ding, Z., Zhao, Y., Wang, C. C., Purnawali, H., & Tang, C. (2012). Stimulus-responsive shape memory materials: a review. Materials & Design, 33, 577-640.

6. Morgan, N. B. (2004). Medical shape memory alloy applications—the market and its products. Materials Science and Engineering: A, 378(1-2), 16-23.