What is shape memory nitinol wire, and how does it work?

2025-01-04 21:44:19

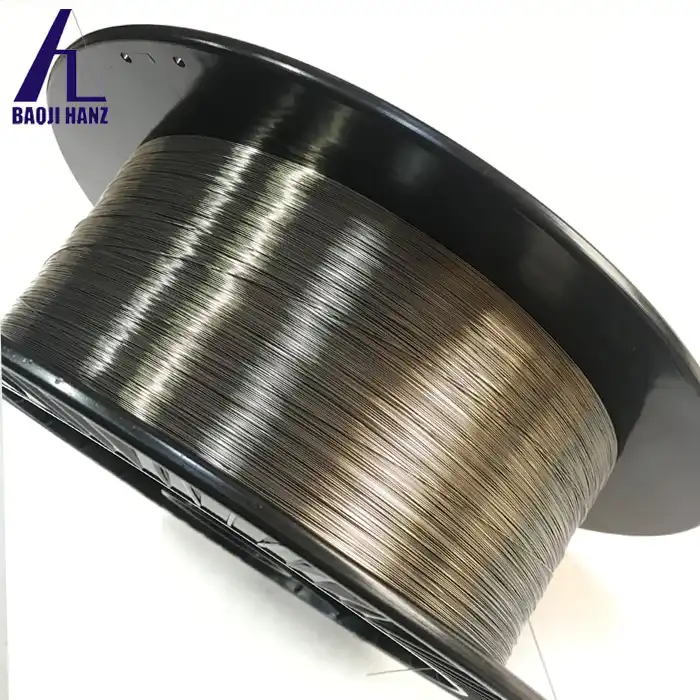

Shape memory nitinol wire is a remarkable material that has revolutionized various industries due to its unique properties. This extraordinary alloy, composed of nickel and titanium, exhibits the ability to "remember" and return to its original shape after deformation when exposed to specific temperatures. In this comprehensive guide, we'll delve into the fascinating world of shape memory nitinol wire, exploring its composition, properties, and diverse applications. From medical devices to aerospace engineering, this versatile material continues to push the boundaries of innovation and technology. Join us as we unravel the mysteries of shape memory nitinol wire and discover how it's transforming the way we approach design and engineering challenges.

The Science Behind Shape Memory Nitinol Wire

Composition and Crystal Structure

Shape memory nitinol wire is an innovative alloy composed of nearly equal parts nickel and titanium, which contributes to its extraordinary properties that have garnered significant interest in various applications. This unique composition gives rise to remarkable characteristics, allowing the material to return to a predetermined shape when subjected to specific conditions. At the atomic level, nitinol exists in two distinct crystal structures: austenite and martensite. The transition between these structures is crucial for understanding the shape memory effect, as it enables the alloy to remember its original shape after deformation. This fascinating behavior has made nitinol wire a popular choice in medical devices, robotics, and various engineering applications, highlighting its versatility and effectiveness in real-world scenarios.

Phase Transformation

The shape memory effect in nitinol wire is driven by a solid-state phase transformation known as the martensitic transformation, which plays a crucial role in the functionality of this remarkable material. This transformation occurs when the material is subjected to changes in temperature or mechanical stress, making it highly responsive to external stimuli. As the temperature increases, the crystal structure shifts from martensite to austenite, triggering the shape memory effect that allows the wire to revert to its predetermined shape. This unique capability is harnessed in various applications, particularly in the fields of medicine and engineering, where precise movements and responses are essential. The ability of nitinol to undergo this transformation enhances its versatility and effectiveness in practical uses across different industries.

Temperature-Dependent Behavior

Nitinol wire exhibits distinct behaviors at various temperatures, which are fundamental to its functionality in practical applications. The transformation temperatures, including the austenite start (As), austenite finish (Af), martensite start (Ms), and martensite finish (Mf) temperatures, play a crucial role in determining the wire's behavior and responsiveness to temperature changes. These specific temperatures are critical in defining how the wire will react under different conditions, impacting its performance in applications such as medical devices and actuators. Importantly, these transformation temperatures can be tailored during the manufacturing process to suit specific applications, allowing engineers and designers to optimize the material's properties for desired outcomes. This customization enhances nitinol’s versatility and makes it a preferred choice in various high-tech fields.

How Shape Memory Nitinol Wire Works

The Shape Memory Effect

The shape memory effect is the hallmark property of nitinol wire. When the wire is deformed at a lower temperature, it remains in that shape until heated above its transformation temperature. Upon heating, the wire "remembers" its original shape and returns to it. This phenomenon occurs due to the reversible phase transformation between martensite and austenite.

Superelasticity

Another fascinating property of shape memory nitinol wire is superelasticity. This occurs when the wire is above its austenite finish temperature. In this state, the wire can undergo large deformations and immediately return to its original shape upon removal of the stress, without the need for heating. This behavior is due to the stress-induced transformation between austenite and martensite.

Training the Wire

To achieve the desired shape memory effect, nitinol wire must undergo a process called "training." This involves repeatedly deforming the wire and heating it to its austenite phase. Through this process, the wire learns to remember a specific shape, which it will return to when heated above its transformation temperature.

Applications of Shape Memory Nitinol Wire

Medical Devices

The biocompatibility and unique properties of shape memory nitinol wire have made it indispensable in the medical field. It's used in various applications, including stents for cardiovascular procedures, orthodontic archwires, and minimally invasive surgical instruments. The wire's ability to change shape at body temperature allows for the creation of self-expanding devices that can be inserted into the body in a compact form and then expand to their functional shape.

Aerospace and Automotive Industries

Shape memory nitinol wire finds numerous applications in aerospace and automotive engineering. Its lightweight nature and shape memory properties make it ideal for actuators, vibration damping systems, and deployable structures. In aircraft, nitinol-based devices can be used for noise reduction and de-icing systems. In automobiles, the wire can be utilized in adaptive headlight systems and climate control vents.

Consumer Electronics

The consumer electronics industry has also embraced shape memory nitinol wire. It's used in mobile phone antennas, laptop hinges, and even in some types of eyeglass frames. The wire's ability to return to its original shape after deformation ensures durability and longevity in these applications, enhancing the user experience and product lifespan.

Conclusion

Shape memory nitinol wire is a remarkable material that continues to captivate scientists, engineers, and innovators across various industries. Its unique ability to remember and return to its original shape, coupled with its superelastic properties, opens up a world of possibilities in medical, aerospace, automotive, and consumer applications. As research in this field progresses, we can expect to see even more groundbreaking uses for this extraordinary alloy in the future. If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1. Otsuka, K., & Wayman, C. M. (Eds.). (1999). Shape memory materials. Cambridge university press.

2. Duerig, T., Pelton, A., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273, 149-160.

3. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design (1980-2015), 56, 1078-1113.

4. Lagoudas, D. C. (Ed.). (2008). Shape memory alloys: modeling and engineering applications. Springer Science & Business Media.

5. Sun, L., Huang, W. M., Ding, Z., Zhao, Y., Wang, C. C., Purnawali, H., & Tang, C. (2012). Stimulus-responsive shape memory materials: a review. Materials & Design, 33, 577-640.

6. Barbarino, S., Flores, E. I. S., Ajaj, R. M., Dayyani, I., & Friswell, M. I. (2014). A review on shape memory alloys with applications to morphing aircraft. Smart Materials and Structures, 23(6), 063001.