What is the difference between superelastic Nitinol and shape memory Nitinol?

2025-02-10 22:14:39

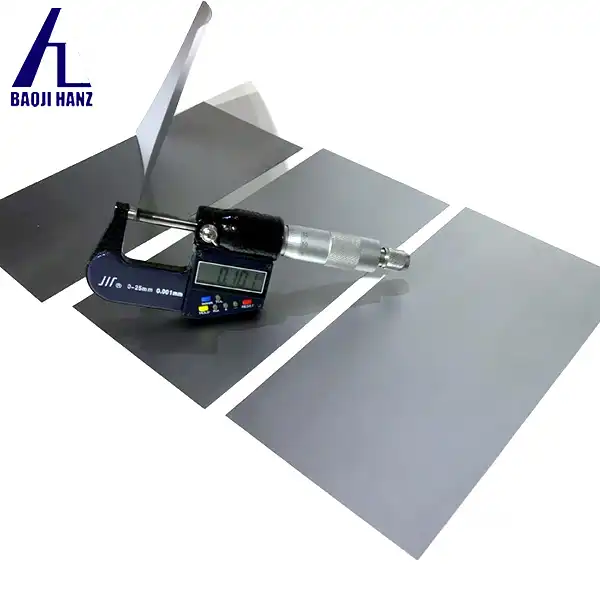

Shape memory nitinol sheet, a remarkable alloy of nickel and titanium, has revolutionized various industries with its unique properties. Two distinct forms of Nitinol stand out: superelastic Nitinol and shape memory Nitinol. While both types share the same chemical composition, their behavior under different conditions sets them apart. This blog delves into the intricacies of these two Nitinol variants, exploring their distinct characteristics, applications, and the science behind their transformative abilities. Understanding the differences between superelastic and shape memory Nitinol is crucial for engineers, researchers, and manufacturers looking to harness the full potential of this versatile material in their projects and innovations.

Understanding the Basics of Nitinol

The Discovery and Composition of Nitinol

William J. Buehler and Frederick Wang discovered Nitinol, which stands for Nickel Titanium Naval Ordnance Laboratory, in 1959. Due to its nearly equal atomic percentages of nickel and titanium, this remarkable alloy has distinctive characteristics that set it apart from other materials. Because of its extraordinary properties, such as the shape-memory effect and superelasticity, the discovery of Nitinol marked a significant turning point in the field of materials science. The way engineers approach design and functionality has been revolutionized as a result of these properties' innovative applications in aerospace, robotics, and medical device industries.

Crystal Structure and Phase Transformations

The remarkable behavior of Nitinol arises from its unique ability to undergo phase transformations at the atomic level, which is fundamental to its extraordinary properties. At elevated temperatures, Nitinol exists in a stable austenite phase characterized by a well-ordered cubic crystal structure. As the temperature decreases, it transitions into a martensite phase, adopting a less ordered monoclinic crystal structure that allows for greater flexibility. This phase transformation is crucial for enabling both shape memory and superelasticity, allowing Nitinol to return to its original shape after deformation when heated or to exhibit significant strain without permanent deformation. These characteristics make Nitinol invaluable in diverse applications.

Unique Properties of Nitinol

Nitinol stands out from other materials thanks to its distinctive combination of properties. Shape memory nitinol sheethas high corrosion resistance and excellent biocompatibility, making it suitable for medical applications. This makes it durable in a variety of environments. Due to its pseudoelastic behavior, Nitinol can withstand significant strains without permanently deforming. Because of this, the material is able to return to its original shape even after undergoing significant deformation. As a result, it is extremely useful for medical devices like stents, guidewires, and other innovative ones that require both flexibility and durability.

Superelastic Nitinol: Characteristics and Applications

Defining Superelasticity in Nitinol

Superelasticity, also known as pseudoelasticity, is a property of Nitinol that allows it to undergo large deformations and return to its original shape upon unloading. This behavior occurs at temperatures above the alloy's austenite finish temperature (Af). When stress is applied, the austenite phase transforms into stress-induced martensite, enabling the material to accommodate large strains. Upon removal of the stress, the martensite reverts to austenite, and the original shape is recovered.

Temperature Range for Superelastic Behavior

The superelastic properties of Shape memory nitinol sheet are most pronounced within a specific temperature range. This range typically lies above the austenite finish temperature (Af) and below the maximum temperature at which stress-induced martensite can form (Md). Within this range, Nitinol can exhibit reversible strains of up to 8%, far exceeding the elastic limit of conventional metals.

Applications of Superelastic Nitinol

The unique properties of superelastic Nitinol have found numerous applications across various industries. In the medical field, it is used in the production of guidewires, stents, and orthodontic archwires. The aerospace industry utilizes superelastic Nitinol in vibration damping systems and flexible aircraft components. Consumer products such as eyeglass frames and cell phone antennas also benefit from the material's superelastic properties, offering enhanced durability and flexibility.

Shape Memory Nitinol: Properties and Uses

The Shape Memory Effect Explained

The shape memory effect in Nitinol refers to its ability to "remember" and return to a predetermined shape when heated above a certain temperature. This phenomenon occurs due to the reversible, temperature-dependent phase transformation between martensite and austenite. When a shape memory Nitinol sheet is deformed at a lower temperature in its martensitic phase, it can be restored to its original austenitic shape by heating it above its transformation temperature.

One-Way vs. Two-Way Shape Memory

Shape memory Nitinol can exhibit either one-way or two-way shape memory effects. In one-way shape memory, the material remembers only its high-temperature austenite shape and requires external force to deform it at lower temperatures. Two-way shape memory allows the material to remember both its high-temperature and low-temperature shapes, enabling it to switch between two predetermined configurations as the temperature changes. The two-way effect is typically achieved through specialized training processes.

Applications Leveraging Shape Memory Properties

The shape memory properties of Nitinol have led to innovative applications across various fields. In the medical industry, shape memory Nitinol is used in self-expanding stents, orthopedic implants, and surgical instruments. The automotive sector employs shape memory Nitinol in thermal actuators and safety devices. Aerospace applications include deployable structures and morphing aircraft components. The unique ability of shape memory Nitinol to respond to temperature changes has also found use in smart fabrics, HVAC systems, and robotics.

Conclusion

The distinction between superelastic and Shape memory nitinol sheet lies in their behavior and activation mechanisms. While superelastic Nitinol exhibits remarkable elasticity at constant temperatures, shape memory Nitinol demonstrates the ability to recover its original form through temperature changes. Both variants offer unique advantages, expanding the possibilities for innovative applications across numerous industries. If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1. Duerig, T. W., & Pelton, A. R. (2019). Nitinol: The Material and its Applications. Journal of Materials Science, 54(15), 10115-10137.

2. Jani, J. M., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

3. Mohd Jani, J., Leary, M., & Subic, A. (2017). Designing shape memory alloy linear actuators: A review. Journal of Intelligent Material Systems and Structures, 28(13), 1699-1718.

4. Otsuka, K., & Ren, X. (2005). Physical metallurgy of Ti–Ni-based shape memory alloys. Progress in Materials Science, 50(5), 511-678.

5. Sun, L., Huang, W. M., Ding, Z., Zhao, Y., Wang, C. C., Purnawali, H., & Tang, C. (2012). Stimulus-responsive shape memory materials: a review. Materials & Design, 33, 577-640.

6. Yamauchi, K., Ohkata, I., Tsuchiya, K., & Miyazaki, S. (Eds.). (2011). Shape memory and superelastic alloys: Technologies and applications. Woodhead Publishing.