Why use nitinol rods?

2024-07-16 16:49:45

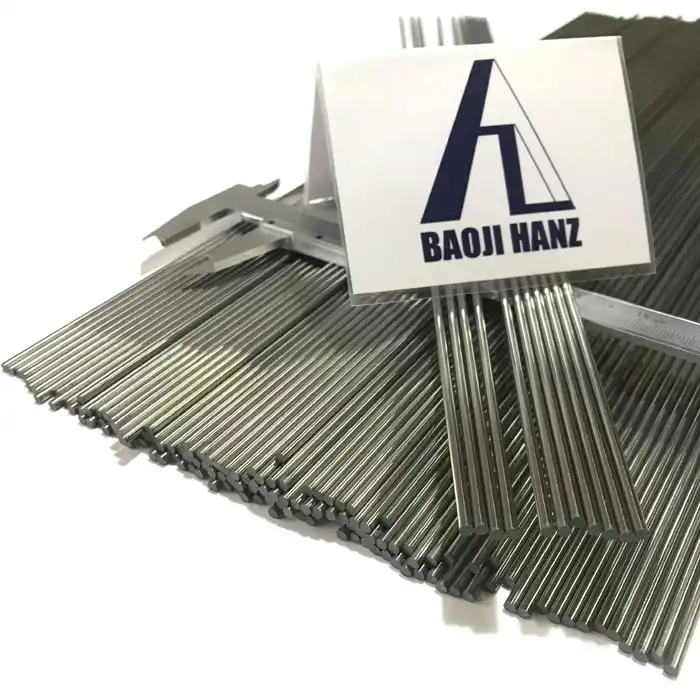

Nitinol rods are favored for their unique combination of properties, notably their shape memory effect and superelasticity. These characteristics allow them to return to a predetermined shape when heated, making them valuable in applications requiring precise and repeatable movements, such as medical devices (like stents and guidewires) and actuators in robotics. Nitinol's ability to withstand large deformations and then recover without permanent damage also makes it ideal for applications where flexibility and durability are essential, such as in aerospace for components like deployable structures and engine components. Overall, nitinol rods offer a versatile solution where controlled shape memory and resilience to deformation are critical requirements.

|

|

|

Why are Nitinol Rods Preferred in Medical Applications?

One of the primary reasons for using Nitinol rods in medical applications is their shape memory and superelasticity properties. These characteristics make Nitinol an ideal material for devices that need to navigate the human body's intricate pathways and then expand or contract to fit a specific shape. For instance, in stent manufacturing, Nitinol is favored because it can withstand significant deformation and recover its original shape when exposed to body temperature. This ability is crucial for minimally invasive procedures, allowing stents to be inserted in a compressed form and then expand to support blood vessels once in place (XOT Metals) (Kellogg's Research Labs).

Additionally, the superelastic property of Nitinol, where the material can endure substantial strain without permanent deformation, contributes to its durability. In cardiovascular applications, such as heart valves and stents, Nitinol's ability to endure millions of cycles of deformation and recovery makes it invaluable (SpringerLink). This durability ensures long-term functionality and reduces the need for repeated surgical interventions.

How Do Nitinol Rods Benefit the Aerospace Industry?

In the aerospace industry, the lightweight nature of Nitinol, combined with its high strength and ability to return to a predetermined shape, provides significant advantages. Nitinol's thermal shape memory allows for the creation of actuators and couplings that can perform specific actions when exposed to temperature changes. This property is particularly useful in the development of morphing wings and other adaptive structures that can change shape in response to environmental conditions, improving aerodynamic efficiency and performance (XOT Metals).

Moreover, the high strength-to-weight ratio of Nitinol rods makes them an excellent choice for aerospace components that must withstand high stresses while contributing minimal additional weight. This is critical in applications such as satellite deployment mechanisms and space exploration tools, where reliability and weight are paramount (Edgetech Industries LLC).

What Makes Nitinol Rods Suitable for Industrial and Consumer Applications?

Beyond medical and aerospace uses, Nitinol rods find extensive applications in various industrial and consumer products due to their robustness and flexibility. For example, Nitinol is used in the manufacture of eyeglass frames, where its ability to return to its original shape after bending enhances durability and longevity. Similarly, in the automotive industry, Nitinol's shape memory properties are harnessed in temperature control systems and other smart components (Edgetech Industries LLC).

In robotics and automation, Nitinol rods are employed in actuators and sensors due to their responsive nature to thermal stimuli. This responsiveness allows for precise control and adaptability in complex machinery. The material's durability also means it can withstand the rigors of continuous operation, reducing maintenance needs and increasing the lifespan of robotic systems (XOT Metals) (Kellogg's Research Labs).

Conclusion

Nitinol rods stand out due to their unique combination of shape memory, superelasticity, high strength, and durability. These properties make them indispensable in medical, aerospace, industrial, and consumer applications, where reliability and performance are crucial. As technology advances, the versatility and capabilities of High-Strength Nitinol Rods and Durable Nitinol Rods will likely lead to even broader uses, continually pushing the boundaries of innovation.

References

- XOT Metals. "Nitinol Rod Properties and Applications." XOT Metals.

- Kellogg's Research Labs. "Why is Nitinol Used in Stents?" Kellogg's Research Labs.

- SpringerLink. "Mechanical Implant Material Selection, Durability, Strength, and Stiffness." SpringerLink.

- Edgetech Industries. "Nitinol Rod (Shape Memory, Superelastic alloy)." Edgetech Industries.