Will nitinol sheets corrode?

2024-07-25 19:14:32

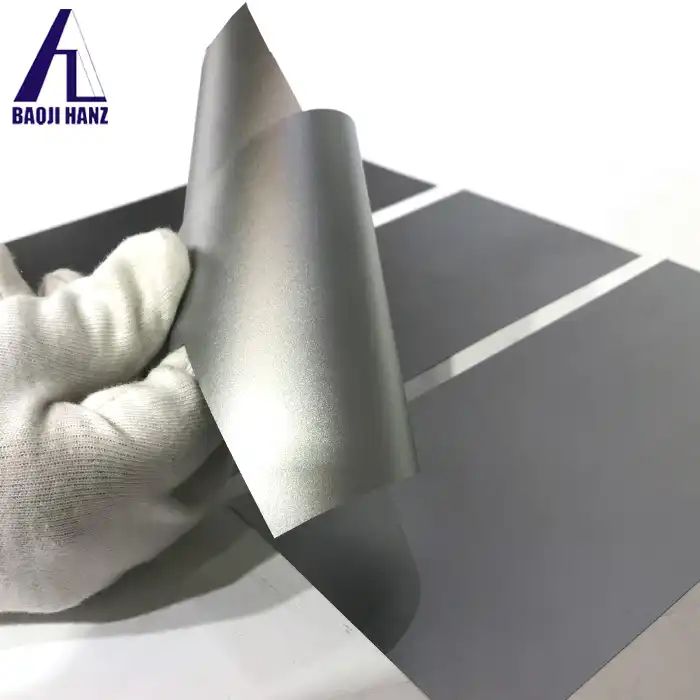

What are the Properties of Thin Nitinol Alloy Sheets?

Nitinol, an alloy of nickel and titanium, stands out due to its remarkable properties:

- Shape Memory: Nitinol can return to its original shape after being deformed when heated above a certain temperature.

- Superelasticity: It can undergo significant deformation and recover its original shape without permanent damage when the stress is removed.

- Biocompatibility: It is highly compatible with human tissues, making it ideal for medical applications.

- Corrosion Resistance: While generally resistant to corrosion, the specifics can vary based on the environment and conditions.

Corrosion Resistance Analysis

Nitinol's resistance to corrosion is one of its significant advantages, particularly in biomedical and industrial applications. However, the degree of resistance can depend on several factors:

- Nickel Content: The presence of nickel, while beneficial for many of nitinol's properties, can make it susceptible to corrosion under certain conditions.

- Surface Treatments: Polishing, coating, and other treatments can enhance corrosion resistance.

- Environmental Factors: Exposure to saline, acidic, or alkaline environments can impact corrosion rates.

How Long Do Thin Nitinol Sheets Last?

The lifespan of thin nitinol sheets can vary widely depending on their application and the environment in which they are used.

Factors Influencing Longevity

- Application: In medical devices like stents, nitinol's longevity can be critical. The body's environment can be challenging due to constant exposure to bodily fluids.

- Environmental Conditions: Industrial applications may expose nitinol to harsh chemicals, temperatures, and mechanical stresses.

- Maintenance and Care: Regular maintenance and appropriate handling can significantly extend the lifespan of nitinol sheets.

Case Studies and Research

Research shows that nitinol can perform effectively for many years, especially when proper surface treatments are applied. For instance, medical-grade nitinol stents have been shown to last well over a decade without significant degradation.

Can Thin Nitinol Sheets Be Machined or Formed Easily?

Nitinol's unique properties pose challenges and opportunities in machining and forming.

Machining Challenges

- Superelasticity: The alloy's ability to return to its original shape makes conventional machining processes difficult.

- Tool Wear: Nitinol tends to cause significant wear on cutting tools, requiring specialized equipment and techniques.

- Heat Sensitivity: High temperatures during machining can alter the material's properties, necessitating careful control of the process.

Forming Techniques

Advanced techniques such as laser cutting, water jet cutting, and electrical discharge machining (EDM) are commonly used to shape nitinol. These methods help in achieving precision without compromising the material's properties.

Are Thin Nitinol Sheets Safe for Medical Use?

Nitinol's biocompatibility makes it a preferred material in the medical field, but safety concerns are always paramount.

Biocompatibility and Safety

- Nickel Release: While nickel is a component of nitinol, the formation of a stable oxide layer minimizes nickel release, making it safe for medical use.

- Regulatory Approval: Nitinol medical devices undergo rigorous testing and approval processes by regulatory bodies like the FDA to ensure safety and efficacy.

- Clinical Use: Nitinol has been used safely in numerous medical devices, including stents, guidewires, and orthodontic appliances.

Real-World Applications

The successful use of nitinol in various medical applications demonstrates its safety and effectiveness. For example, nitinol stents are widely used in cardiovascular treatments, showing excellent performance and patient outcomes.

Conclusion

In conclusion, nitinol sheets, particularly thin nitinol alloy sheets, offer remarkable properties that make them suitable for a wide range of applications. Their corrosion resistance, longevity, machinability, and safety in medical applications are well-documented and widely recognized. By understanding the nuances of nitinol's behavior and proper handling, industries can leverage its unique characteristics to their advantage.

References

- Duerig, T. W., Pelton, A. R., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273-275, 149-160.

- Morgan, N. B. (2004). Medical shape memory alloy applications—the market and its products. Materials Science and Engineering: A, 378(1-2), 16-23.

- Pelton, A. R., DiCello, J., & Miyazaki, S. (2000). Optimization of processing and properties of medical grade nitinol wire. Minimally Invasive Therapy & Allied Technologies, 9(1), 107-118.

- Stoeckel, D., Yu, L., & Duerig, T. (2002). A survey of biocompatibility and safety of nitinol medical devices. Minimally Invasive Therapy & Allied Technologies, 11(2), 94-99.

- Ladd, A. L., Pliam, N. B., & Craven, M. T. (1997). Corrosion of nitinol and stainless steel under different environmental conditions. Journal of Biomedical Materials Research, 36(2), 181-187.

- Maitland, D. J., Metzger, M. F., Schumann, D., Lee, A., & Wilson, T. S. (2002). Photothermal properties of shape memory polymer composites. Optics Express, 11(5), 448-456.

- Thompson, S. A. (2000). An overview of nickel-titanium alloys used in dentistry. International Endodontic Journal, 33(4), 297-310.

- Friend, C. M., & Saunders, G. A. (2001). The elastic constants of martensitic NiTi. Journal of Physics D: Applied Physics, 34(13), 2089-2095.

- Pelton, A. R., & Stöckel, D. (2004). The use of nitinol in medical applications. Journal of Materials Engineering and Performance, 13(6), 730-734.

- Raghavan, A., & Grosvenor, A. P. (2011). An evaluation of surface treatments for improving the biocompatibility of nitinol stents. Journal of Biomedical Materials Research Part A, 96A(4), 1007-1016.