Product Introduction

Welcome to Baoji Hanz Metal Material Co., Ltd., where we specialize in high-quality nitinol coil springs crafted from advanced nitinol shape memory alloys. Established in 2017 in the heart of the Baoji Titanium Valley, our company is dedicated to innovation and excellence in manufacturing. Our nitinol coil springs are renowned for their unique properties, including superelasticity and shape memory effect, making them ideal for various applications in industries ranging from medical devices to aerospace engineering.

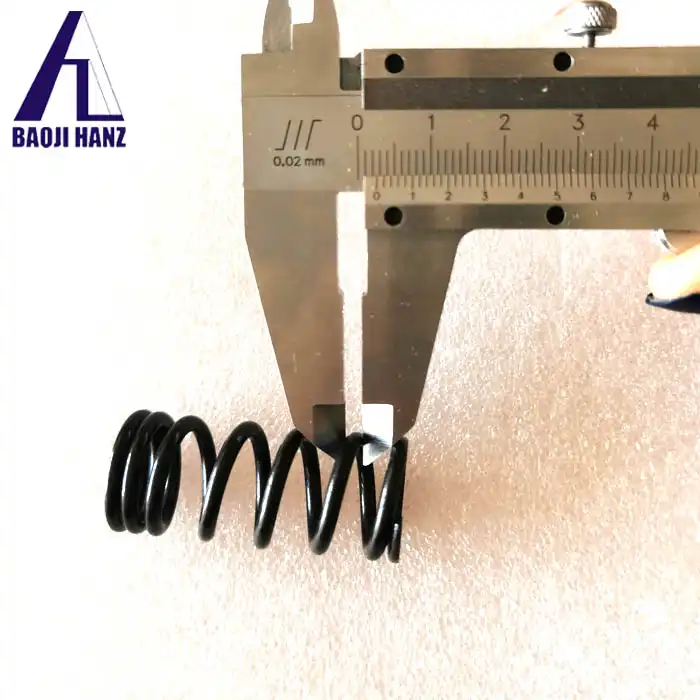

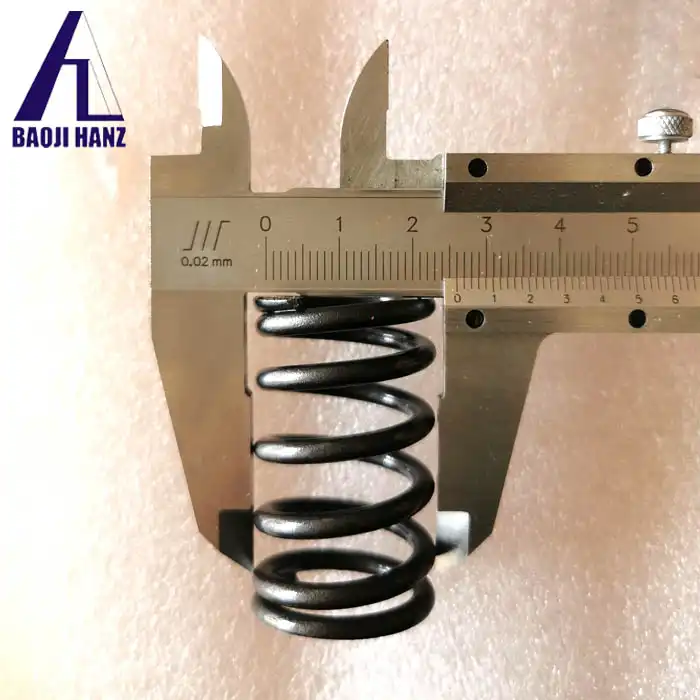

Product Specifications

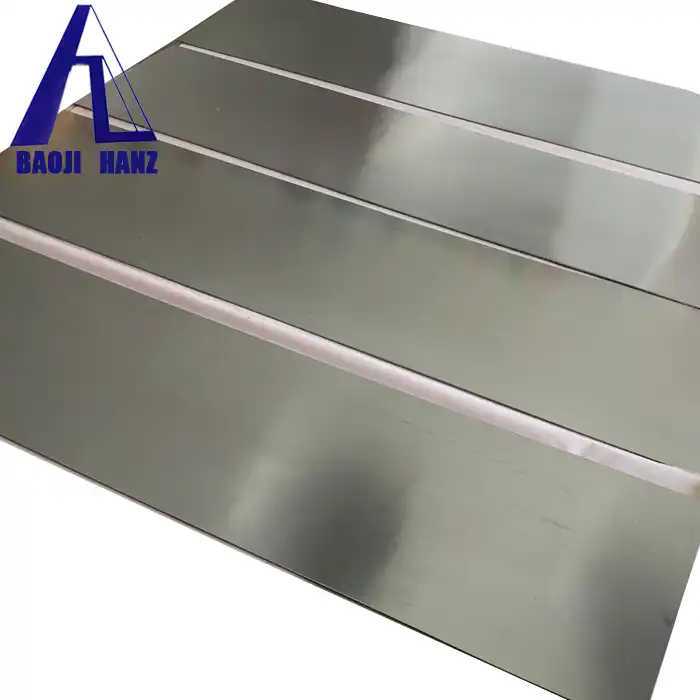

Nitinol coil spring have shape memory and super elastic spring materials. It is composed of an alloy of nickel and titanium, with high elastic modulus and high resilience, and can be restored to its original form after deformation. This alloy material is widely used in medical, aviation, automotive, machinery manufacturing and other industries, in the medical field, tungsten titanium springs are used to manufacture medical devices such as brackets, teeth molars. In the aviation field, it is used to make aircraft landing gear shock absorbers, mainly because of its high strength and high heat resistance. In the automotive sector, it is used to make components such as valve springs, transmissions, and suspension systems. In general, nickel-titanium spring has good plasticity, corrosion resistance and oxidation resistance, and has a wide range of application prospects.

Grade:Titanium nickel alloy

Ti (Min):45%

Strength:240

Processing Service:Cutting

Surface:Polished

Material:45%titanium and 55%nickel

Shape:Coil Roll

MOQ:1kg

Diameter:0.1~5.0mm

Feature:Shape Memory

Use: Industrial

|

Product name |

Fully Annealing Af |

Main Applications |

Specifications |

|

|

Superelastic/shape memory |

TiNi-SS |

-5°C ± 5°C. |

Eyeglass |

Q/XB1516.2 |

|

TN3 |

-40°C ~50°C |

|||

|

Body temperature |

TiNi-YY |

Functional |

Implantable |

ASTM 2063 |

|

Ti-Ni-01 |

20 - 40 |

Guide wires, |

Q/XB1516.1 |

|

|

High temperature |

Ti-Ni-02 |

45 - 95 |

Implantable |

Q/XB1516.1 |

Product Advantages

- High Qualit: Our nitinol coil springs are meticulously manufactured using state-of-the-art production techniques. This commitment to innovation not only ensures that each spring meets rigorous international standards for quality and safety but also enhances performance and reliability in various applications.

- Versatility: Thanks to the unique properties of nitinol, our coil springs are incredibly versatile, making them suitable for a diverse range of industries, from medical devices to automotive applications. Their shape memory and superelasticity allow for innovative designs that can adapt to different environments and requirements.

- Competitive Pricing: We pride ourselves on offering reasonable prices that do not compromise quality. By maintaining high production standards while optimizing our processes, we provide exceptional value to our customers, helping them achieve their project goals within budget.

- Stable Supply Chain: Our robust supply chain ensures timely delivery of our products, allowing us to meet your production needs efficiently. With established partnerships and a commitment to reliability, we guarantee that you will receive your orders on time, enabling seamless integration into your manufacturing processes.

Technical Features

-

Shape Memory Effect: Nitinol, a unique alloy of nickel and titanium, possesses the remarkable ability to return to its original shape after being deformed when exposed to heat. This characteristic is not only fascinating but also opens up innovative solutions in diverse applications, such as medical devices, where implants can adapt to specific anatomical shapes and restore functionality without additional procedures.

Superelastic Properties: One of Nitinol's standout features is its superelasticity, allowing the material to endure substantial deformation while effortlessly reverting to its original shape. This property is particularly advantageous in dynamic applications, such as in robotics and aerospace, where components must withstand significant stress and strain while maintaining their integrity and performance.

Corrosion Resistance: In addition to its mechanical properties, Nitinol is renowned for its exceptional corrosion resistance. This characteristic ensures that it remains reliable and effective in various environments, including harsh or corrosive conditions. As a result, Nitinol components not only exhibit longevity but also require less maintenance, making them a preferred choice in industries like biomedical and aerospace engineering.

Nickel-titanium spring use method

1. Storage of nickel-titanium spring: storage should avoid pits or scratches on the surface or central part of the spring, so as not to affect the use effect, storage should be placed in a dry, well-ventilated environment, and properly packaged.

2. Installation of nickel-titanium spring: The installation of nickel-titanium spring should try to ensure that the axial position of the spring is correct, do not distort or deform the spring, so as not to damage the texture of the spring surface. Apply lubricant to surfaces in contact with other components to reduce wear.

3, the use of nickel-titanium spring: when using nickel-titanium spring should try to avoid exceeding its elastic limit, so as to avoid abnormal bending and deformation. After normal use, the spring should be regularly checked for fatigue cracks, deformation or surface wear.

4. Maintenance of nickel-titanium spring: clean and maintain the spring regularly, maintain a dry and ventilated environment, and prevent corrosion of the spring surface. At the same time, pay attention to avoid overuse and long-term non-use, so as not to affect the service life.

Product Applications

They are widely used in:

- Medical Devices: Such as stents and guidewires, where flexibility and reliability are critical.

- Aerospace: For components that require durability under extreme conditions.

- Robotics: In actuators and mechanisms where precise movement is essential.

OEM Service

At Baoji Hanz Metal Material Co., Ltd., we offer OEM services to customize nitinol coil springs according to your specifications. Our professional team works closely with clients to develop tailored solutions that meet specific project requirements.

Company and equipment

Production process

Shipping

FAQ

Q: What is the lead time for orders?

A: We prioritize timely delivery and typically ship orders within [insert standard lead time] after receiving payment.

Q: Can I get a sample before placing a large order?

A: Yes, we offer free samples for your evaluation.

Q: Are your products certified?

A: Yes, all our products are certified under ISO9001:2015 and ISO13485:2016 standards.

Q: Do you provide technical support?

A: Absolutely! Our experienced team is here to provide guidance on product applications and formulations.

Q: What payment methods do you accept?

A: We accept various payment methods, including bank transfers and credit cards.

Contact Us

For more information about our nitinol coil springs or to place an order, please reach out to us at baojihanz-niti@hanztech.cn. Our dedicated sales team is ready to assist you and help you find the perfect solution for your needs.

Send Inquiry

.webp)