Baoji Hanz Metal Material Co., Ltd.: Your Trusted ASTM F2063 Superelastic Nitinol Tube Manufacturer & Supplier

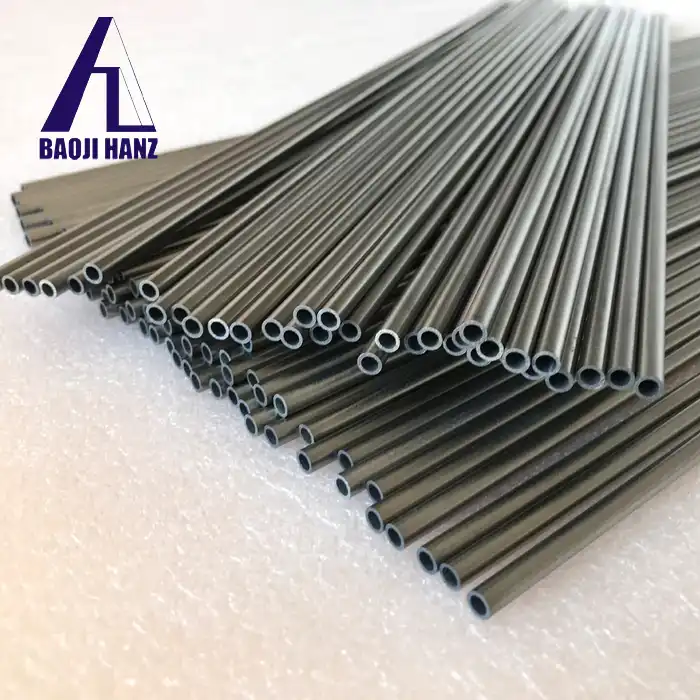

The ASTM F2063 Superelastic Nitinol Tube is an elite exhibition composite tube known for its excellent flexibility and strength.

Nitinol, a nickel-titanium compound, shows extraordinary properties like superelasticity and shape memory, making it ideal for different innovative applications. This tube adjusts to the ASTM F2063 standard, guaranteeing its quality and reasonableness for clinical and modern purposes.

ASTM F2063 Superelastic Nitinol Tube Introduction

One of the vital highlights of this Nitinol tube is its capacity to get back to its unique shape after disfigurement, a property profoundly esteemed in clinical gadgets like stents, guidewires, and orthodontic archwires.

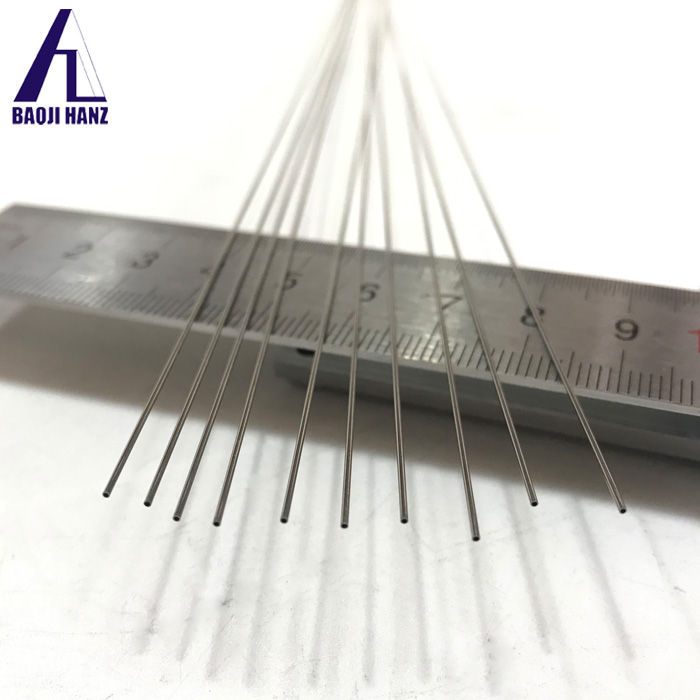

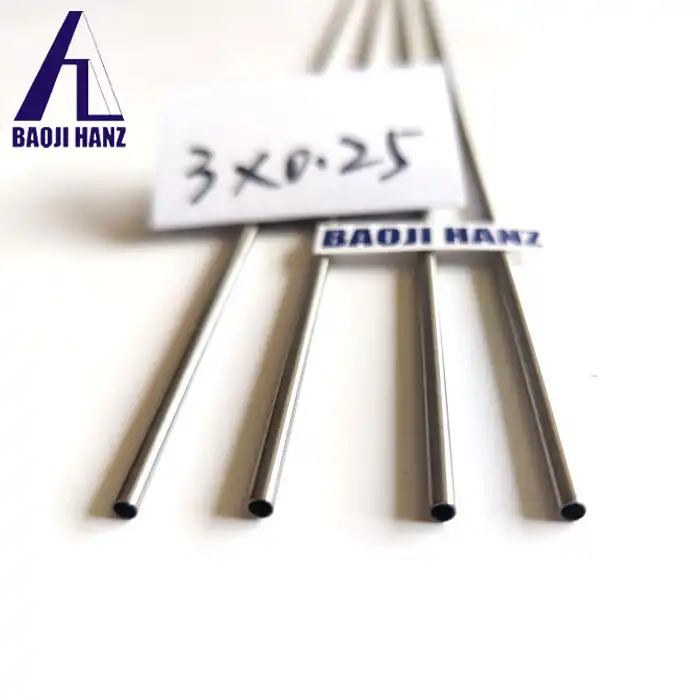

Manufactured to precise specifications, these tubes offer consistent performance and reliability. They can be easily integrated into various systems, providing engineers and designers with a versatile material for innovative solutions. Whether in life-saving medical devices or cutting-edge technology, the ASTM F2063 Superelastic Nitinol Tube stands out for its remarkable properties and quality.

|

|

|

|

|

|

Specifications

| Place of Origin | Shaanxi, China |

| Brand Name | Baoji hanz |

| Color | Bright |

| Materials | Nitinol alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 45% |

| Processing Service | Bending, Decoiling, Cutting, Punching |

| Feature | Superelastic |

| Technique | Seamless |

| Shape | Round Shape |

| Supply Status | Annealling |

| The Max recovery stress | 1200Mpa |

| Standard | ASTM F2063-12/18 |

| Certificate | ISO9001:2015 |

| Application | Catheter / stents |

| Chemical element | Af range | Available production Line | Usage | Sample |

| Nickel 55% Titanium 45% | 0℃to 100℃ | Rod&wire,Plate&sheet,Strip&foil | Medical&Industry | On stock (various specification) |

| Nickel 55% +V +Ti | ||||

| Nickel 55% +Fe +Ti | Subzero 30℃ to -5 ℃ | Rod&wire,Plate&sheet | Industry | On stock |

| Nickel 55%+Cr +Ti | (limitedspecification) | |||

| Nickel 55% +Hf +Ti | Above 100C | Ingot | Ingot | updating |

Application Areas

The ASTM F2063 Nitinol Tube is renowned for its versatility and is utilized across various advanced fields due to its unique properties. One of the primary application areas is in the medical industry, where it is used extensively in devices such as stents, guidewires, and orthodontic archwires. These medical devices benefit from the tube's superelasticity, which allows them to conform to body structures and return to their original shape, enhancing patient outcomes.

In the aerospace sector, the Nitinol tube's lightweight and high strength-to-weight ratio make it ideal for components that require durability and flexibility under extreme conditions. It is used in actuators, fasteners, and other critical parts that must withstand significant stress and temperature variations.

Robotics and automation also benefit from the use of ASTM F2063 Superelastic Nitinol Pipes. The tubes are incorporated into robotic joints and actuators, providing the necessary flexibility and resilience for precise movements and repetitive tasks.

Additionally, the consumer electronics industry uses Nitinol tubes in devices that require compact, yet robust, components. For example, they are found in the flexible joints of smartphones and wearable technology, where their ability to bend and return to shape enhances the user experience.

Features

- Superelasticity and shape memory properties

- High durability and resistance to corrosion

- Precise dimensions and uniformity

- Suitable for sterilization processes

- Versatile applications in medical and engineering fields

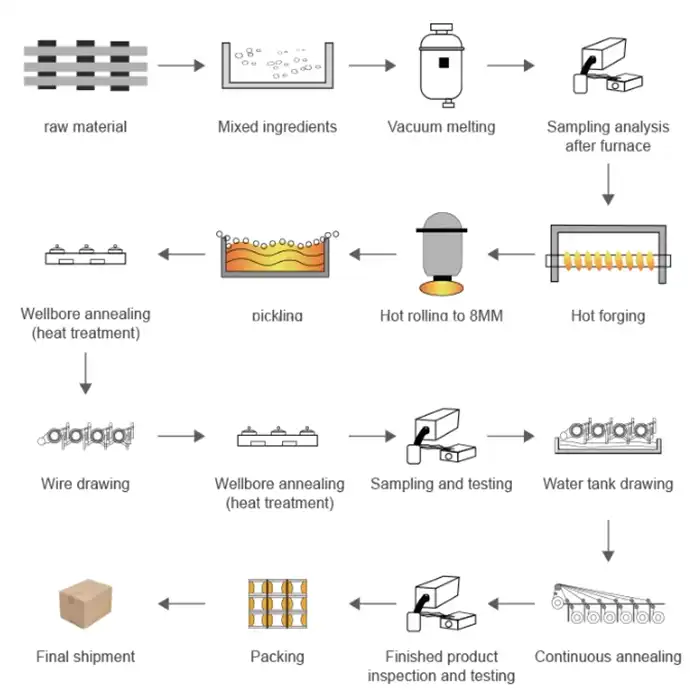

Production Technology

Our ASTM F2063 Superelastic Nitinol Tube is manufactured using advanced processing techniques such as hot extrusion and cold drawing to achieve the desired mechanical properties and dimensional accuracy. Each stage of production is carefully monitored to ensure consistency and quality.

Quality Control

Stringent quality control measures are implemented throughout the manufacturing process to guarantee the reliability and performance of our product. This includes comprehensive testing for mechanical properties, dimensional accuracy, and surface finish.

Manufacturing Technique

Transportation

FAQ

- Q: What is the maximum elongation of the superelastic nitinol pipe?

- A: The maximum elongation is approximately 8%.

- Q: Can the tube be customized to specific dimensions?

- A: Yes, we offer customization services to meet your specific requirements.

Contact Us

Baoji Hanz Metal Material Co., Ltd. is a professional ASTM F2063 Superelastic Nitinol Tube manufacturer and supplier with a state-of-the-art factory, large inventory, and complete certifications. We guarantee fast delivery and excellent customer service. For inquiries or orders, please contact us at E-mail: hztech01@hanztech.cn

.webp)