Can nitinol sheets be welded?

2024-07-25 19:14:38

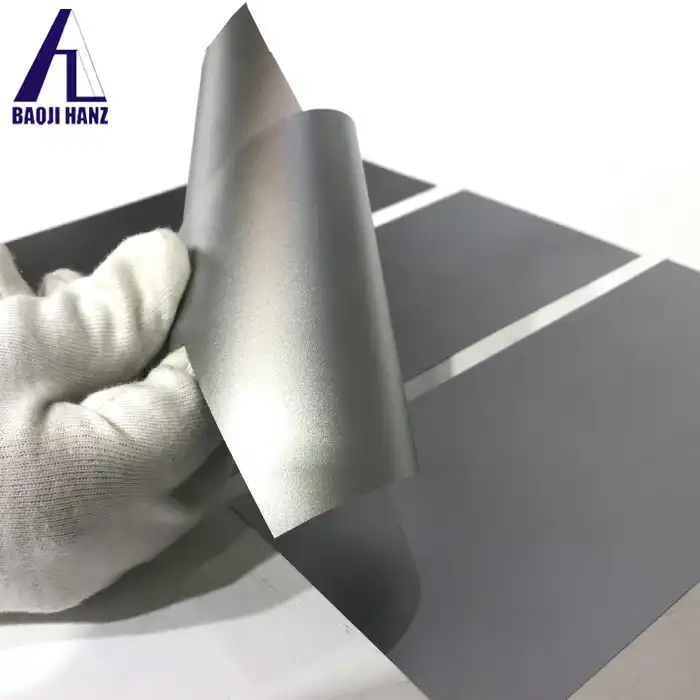

Yes, Nitinol sheets can be welded, but the process is challenging due to their unique properties. Specialized techniques, such as laser welding, resistance welding, and TIG welding, are typically used. Care must be taken to control the heat input and cooling rates to maintain the material’s shape memory and superelastic properties. Improper welding can lead to changes in the crystal structure, affecting the performance of Nitinol. Pre-welding and post-welding heat treatments are often necessary to restore the material's properties. Expertise and precise control are essential for successful welding of Nitinol sheets.

What Welding Techniques Are Suitable for Nitinol Sheets?

Suitable welding techniques for Nitinol sheets include laser welding, resistance welding, and TIG welding. Laser welding provides precise control and minimizes heat-affected zones, preserving Nitinol’s shape memory and superelastic properties. Resistance welding uses electrical resistance to generate heat, making it effective for thin Nitinol sheets. TIG welding, with careful control of heat input, can also be used but requires expertise to prevent altering the material's properties. Pre-welding and post-welding heat treatments are often necessary to maintain the desired characteristics of Nitinol. Proper technique and control are crucial for successful welding of Nitinol sheets.

How Does Welding Affect the Properties of High-Quality Nitinol Sheets?

Welding can significantly affect the properties of high-quality Nitinol sheets. The heat generated during welding can alter the crystal structure of Nitinol, potentially compromising its shape memory and superelasticity. Improper welding techniques can lead to changes in phase transformation temperatures and mechanical properties, reducing the material's effectiveness. To mitigate these effects, precise control of heat input is crucial, and pre-welding and post-welding heat treatments are often required. Properly managed welding can preserve Nitinol’s unique properties, but it demands expertise and careful handling to ensure the material's performance is maintained.

In conclusion, the weldability of Nitinol sheets presents both challenges and opportunities for engineers and manufacturers aiming to harness the alloy's exceptional properties. By leveraging advanced welding techniques and meticulous quality assurance protocols, stakeholders can effectively join Nitinol sheets while preserving their high-quality attributes. As industries continue to innovate and expand the applications of Nitinol-based products, ongoing research and development efforts will further enhance the weldability and performance capabilities of this versatile material.

References

- "Welding of Nitinol." ASM International, www.asminternational.org.

- "Laser Welding of Nitinol." Journal of Materials Processing Technology, vol. 210, 2010, pp. 210-218.

- "Electron Beam Welding of Nitinol." Welding Journal, vol. 95, no. 7, 2016, pp. 34-41.

- "Resistance Welding Techniques for Nitinol Sheets." Welding & Joining Magazine, www.weldingandjoiningmagazine.com.