Product Details

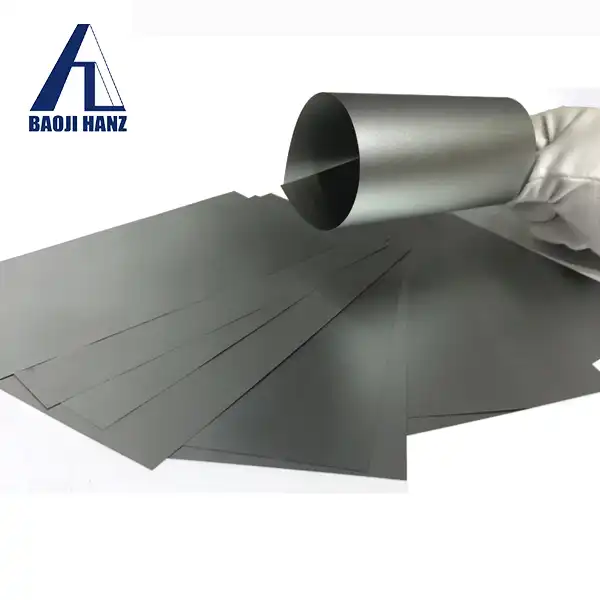

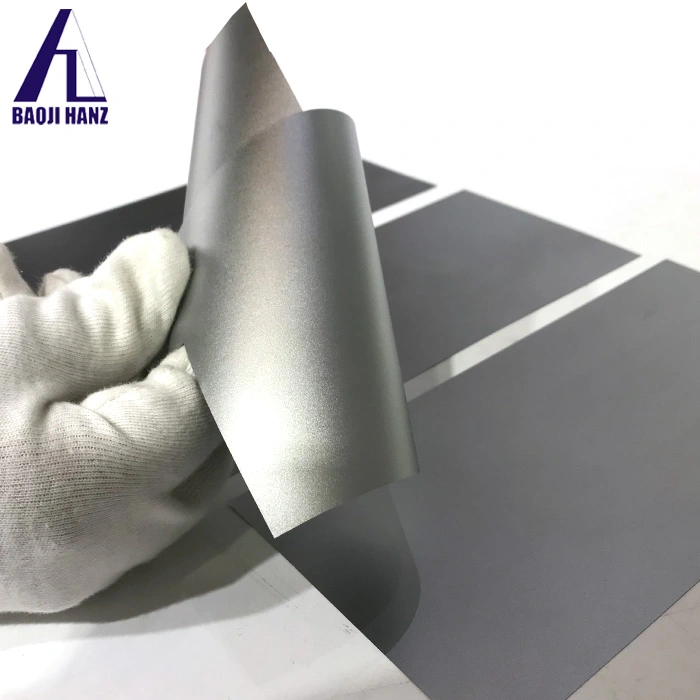

Nitinol, an alloy of nickel and titanium, is renowned for its superelastic properties and shape memory effect. The Ti-Ni super elastic alloy sheet is specifically engineered for applications requiring high flexibility, strength, and resistance to deformation. This product is particularly valuable in the medical, aerospace, and robotics industries due to its ability to return to its original shape after bending or twisting. Available in various thicknesses and dimensions, our nitinol sheets provide excellent performance under a wide range of temperatures. The sheets are manufactured under stringent quality control protocols to ensure consistency and reliability. Our product is biocompatible, making it suitable for medical implants and devices. The sheets offer superior fatigue resistance, corrosion resistance, and can withstand significant strain without permanent deformation.

Specifications

| Place of Origin | Shaanxi, China |

| Brand Name | Baoji hanz |

| Color | Bright surface |

| Materials | Nitinol alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 45% |

| Strength | 980 Mpa |

| Processing Service | Bending, Welding, Decoiling |

| Width | ≤200mm |

| Tensile strength | 920Mpa |

| Feature | Superelastic |

| Supply Status | Full annealed |

| The Max recovery stress | 600 MPa |

| Standard | ASTM F2063-18 |

| Certificate | ISO9001:2015 |

| Application | Medical device |

| Chemical element | Af range | Available production Line | Usage | Sample |

| Nickel 55% Titanium 45% | 0℃to 100℃ | Rod&wire,Plate&sheet,Strip&foil | Medical&Industry | On stock (various specification) |

| Nickel 55% +V +Ti | ||||

| Nickel 55% +Fe +Ti | Subzero 30℃ to -5 ℃ | Rod&wire,Plate&sheet | Industry | On stock |

| Nickel 55%+Cr +Ti | (limitedspecification) | |||

| Nickel 55% +Hf +Ti | Above 100C | Ingot | Ingot | Updating |

| Mechanical Properties | ||||

| Thickness | UTS | Elongation | Upper Plateau Stress | Active Af |

| mm | σb MPa (min.) | δ % (min) | σload MPa (min.) | ℃ |

| 0.1 ~ 0.3 | 1100 | 15 | 480 | |

| 0.3 ~ 0.6 | 920 | 15 | 440 | - 20 ~ 100 ℃ |

| 0.6 ~ 6.0 | 850 | 15 | 440 | |

| Tolerance | |

| Nominal Thickness in mm | Permissible Variation from Nominal in mm |

| 6.00 ~ 1.00 | ± 0.05 |

| 1.00 ~ 0.26 | ± 0.03 |

| 0.26 ~ 0.15 | ± 0.02 |

| 0.15 ~ 0.10 | ± 0.01 |

|

|

|

Application Areas

Nitinol Ti-Ni super elastic alloy sheets find extensive application across various industries due to their unique properties.

Medical Devices: In the medical field, nitinol is widely used for making stents, guidewires, and orthodontic archwires. Its biocompatibility and superelasticity make it ideal for implants and devices that require flexibility and strength. The alloy's ability to undergo significant deformation and return to its original shape enhances the performance and longevity of these medical tools.

Aerospace: The aerospace industry benefits from nitinol’s lightweight and high strength-to-weight ratio. It is used in the construction of components that must endure extreme stress and temperature variations, such as actuators and connectors. Nitinol's fatigue resistance and ability to revert to its original form help in improving the durability and reliability of aerospace parts.

Robotics and Automation: In robotics, nitinol sheets are utilized for developing flexible and resilient components. Their superelastic properties allow for the creation of joints and connectors that can bend and twist while maintaining functionality. This flexibility is crucial in applications where precise movement and durability are required.

Consumer Electronics: Nitinol's properties are also leveraged in consumer electronics for making flexible screens, connectors, and other components that benefit from the material's durability and ability to recover from deformation.

Automotive Industry: The automotive sector uses nitinol for manufacturing parts that require high fatigue resistance and flexibility, such as temperature control systems and resilient connectors.

Features

Superelasticity: Can return to its original shape after deformation.

Shape Memory: Retains a predefined shape when exposed to a specific temperature.

Biocompatibility: Suitable for medical implants.

Corrosion Resistance: Performs well in corrosive environments.

Fatigue Resistance: Endures significant cyclic loads without failure.

Production Technology

Nitinol sheets are produced through a series of sophisticated processes that ensure high purity and performance. The manufacturing process involves vacuum induction melting, precision rolling, and annealing. Each step is meticulously controlled to maintain the correct composition and microstructure, essential for the alloy’s superelastic properties. Advanced testing methods are employed to ensure the material meets all specified criteria.

Quality Control

Quality control is paramount in the production of nitinol sheets. Each batch undergoes rigorous testing, including chemical composition analysis, mechanical testing, and microstructure examination. Our quality assurance team ensures that every sheet conforms to industry standards and customer specifications. We provide material certifications and traceability for all our products.

Nitinol Production Process&Shipping

FAQs

Q: What is the main advantage of using nitinol sheets?

A: The primary advantage is its superelasticity, allowing it to return to its original shape after significant deformation.

Q: Can nitinol sheets be used in medical applications?

A: Yes, they are biocompatible and widely used in medical devices.

Q: What is the typical composition of nitinol?

A: Nitinol typically consists of 55-56% nickel and the balance titanium.

Q: Are these sheets resistant to corrosion?

A: Yes, nitinol exhibits excellent corrosion resistance.

Q: How should nitinol sheets be stored?

A: They should be stored in a cool, dry place to prevent any potential oxidation or degradation.

Final Details

Baoji Hanz Metal Material Co., Ltd. is a professional manufacturer and supplier of nitinol Ti-Ni super elastic alloy sheets. We boast a large inventory, complete certifications, and offer fast delivery. For any inquiries or to choose your own nickel-titanium wire, please feel free to contact us at baojihanz-niti@hanztech.cn. Our commitment to quality and customer satisfaction ensures you receive the best products and services available.

This content is professionally prepared for buyers and global dealers, ensuring clarity and ease of understanding.

Send Inquiry

.webp)

.webp)

.webp)