How does superelastic nitinol wire work?

2024-10-28 21:20:41

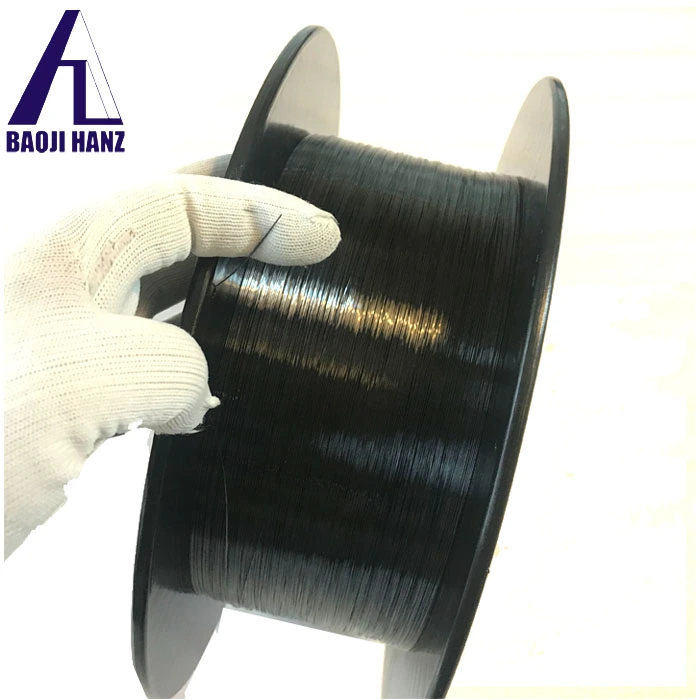

Superelastic nitinol wire, a marvel of modern materials science, has revolutionized various industries with its unique properties. This remarkable alloy, composed of nickel and titanium, exhibits an extraordinary ability to undergo significant deformation and return to its original shape without permanent damage. In this comprehensive exploration, we'll delve into the fascinating world of superelastic nitinol wire, uncovering its working principles, applications, and the science behind its seemingly magical behavior. From medical devices to aerospace engineering, this versatile material continues to push the boundaries of what's possible in material design and functionality.

The Science Behind Superelastic Nitinol Wire

Crystal Structure and Phase Transformations

The exceptional properties of superelastic nitinol wire stem from its unique crystal structure and ability to undergo phase transformations. At higher temperatures, nitinol exists in an austenite phase, characterized by a cubic crystal structure. When stress is applied, the material transitions to a martensite phase, which has a monoclinic crystal structure. This phase transformation is reversible and occurs without the need for temperature changes, allowing the wire to exhibit its superelastic behavior.

Stress-Induced Martensitic Transformation

The key to superelasticity lies in the stress-induced martensitic transformation. When a load is applied to nitinol wire in its austenitic state, it begins to transform into martensite. This transformation allows the material to accommodate large strains without permanent deformation. As the stress increases, more of the austenite transforms into martensite, enabling the wire to undergo significant elongation or bending.

Reversible Deformation Mechanism

Upon removal of the applied stress, the martensite phase becomes unstable at room temperature. The material then reverts back to its original austenitic structure, causing the wire to return to its initial shape. This reversible transformation is what gives superelastic nitinol wire its remarkable ability to "remember" its original form, even after substantial deformation. The process occurs without the need for heating, distinguishing it from the shape memory effect observed in other nitinol applications.

Unique Properties of Superelastic Nitinol Wire

Exceptional Elasticity and Recovery

Superelastic nitinol wire exhibits an extraordinary elastic range, far surpassing that of conventional metals. It can undergo strains of up to 8% without permanent deformation, compared to less than 1% for most metals. This remarkable elasticity allows nitinol wire to be bent, twisted, or stretched to extreme degrees and still return to its original shape upon stress removal. The material's ability to recover from large deformations makes it invaluable in applications requiring flexibility and resilience.

Biocompatibility and Corrosion Resistance

Another crucial property of superelastic nitinol wire is its excellent biocompatibility. The material forms a stable titanium oxide layer on its surface, making it highly resistant to corrosion and suitable for use in medical implants and devices. This characteristic, combined with its mechanical properties, has led to widespread adoption in the medical field for applications such as stents, guidewires, and orthodontic archwires. The corrosion resistance of nitinol also extends its usefulness in marine and other harsh environments.

Temperature Independence

Unlike shape memory nitinol, which requires temperature changes to induce shape recovery, superelastic nitinol wire operates independently of temperature within a specific range. This temperature independence allows for consistent performance across varying environmental conditions, making it suitable for applications where temperature fluctuations are common. The material maintains its superelastic properties over a wide temperature range, typically from about -20°C to 80°C, depending on the specific alloy composition.

Applications of Superelastic Nitinol Wire

Medical Devices and Implants

The medical field has embraced superelastic nitinol wire for its unique combination of properties. In cardiovascular applications, nitinol stents can be compressed into a small diameter for insertion into blood vessels and then expand to their predetermined shape once in place. Orthodontic archwires made from nitinol provide consistent, gentle force for tooth movement over extended periods. Surgical instruments benefit from the material's flexibility and kink resistance, allowing for improved maneuverability in minimally invasive procedures.

Aerospace and Automotive Industries

In aerospace applications, superelastic nitinol wire finds use in vibration damping systems and adaptive structures. Its ability to withstand large deformations without fatigue makes it ideal for applications subject to repeated stress cycles. The automotive industry utilizes nitinol in various components, including actuators and sensors, where its shape recovery properties can be harnessed for functional designs. The material's high fatigue resistance and reliability contribute to improved safety and performance in these demanding environments.

Consumer Products and Robotics

The unique properties of superelastic nitinol wire have also found their way into consumer products and robotics. Eyeglass frames made with nitinol are nearly indestructible, able to bend and twist without breaking. In robotics, the material is used in artificial muscles and flexible actuators, enabling the creation of more adaptable and resilient robotic systems. The wire's ability to undergo large deformations and return to its original shape opens up new possibilities for innovative product designs and mechanisms in various industries.

Conclusion

Superelastic nitinol wire stands as a testament to the power of materials science in driving innovation across industries. Its unique ability to undergo substantial deformation and return to its original shape, coupled with biocompatibility and corrosion resistance, makes it an invaluable material in medical, aerospace, and consumer applications. As research continues, the potential for new uses of this remarkable alloy continues to expand, promising further advancements in technology and design. If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1. Otsuka, K., & Wayman, C. M. (Eds.). (1998). Shape memory materials. Cambridge University Press.

2. Duerig, T., Pelton, A., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273-275, 149-160.

3. Miyazaki, S., Fu, Y. Q., & Huang, W. M. (Eds.). (2009). Thin film shape memory alloys: fundamentals and device applications. Cambridge University Press.

4. Jani, J. M., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

5. Morgan, N. B. (2004). Medical shape memory alloy applications—the market and its products. Materials Science and Engineering: A, 378(1-2), 16-23.

6. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.