Product Details

Our Astm F2063 nitinol wire superelastic is a flexible material designed to display striking shape memory and superelasticity. Made out of a nickel and titanium compound, this item offers exceptional adaptability, sturdiness, and biocompatibility. These properties make it profoundly reasonable for a large number of uses across different enterprises, including clinical gadgets, aviation, car, and mechanical technology.

In the clinical field, our product is used in the assembling of stents, guidewires, and other basic careful instruments because of its capacity to get back to its unique shape after twisting, guaranteeing dependability and security. In aviation and car applications, its high weariness obstruction and solidarity to-weight proportion add to improving execution and diminishing by and large weight, which is vital for eco-friendliness and underlying trustworthiness.

In advanced mechanics and other modern applications, the wire's superelastic properties consider creative plan arrangements that expect parts to go through huge disfigurement while keeping up with their utilitarian respectability.

Our Nitinol wire is created with exact designing and exposed to thorough quality control checks, guaranteeing predictable execution and dependability in different conditions. Whether it's for state of the art clinical innovation or high level modern hardware, our nitinol wire price remains as a demonstration of development and quality.

Specifications

| Place of Origin | Shaanxi, China |

| Brand Name | Baoji hanz |

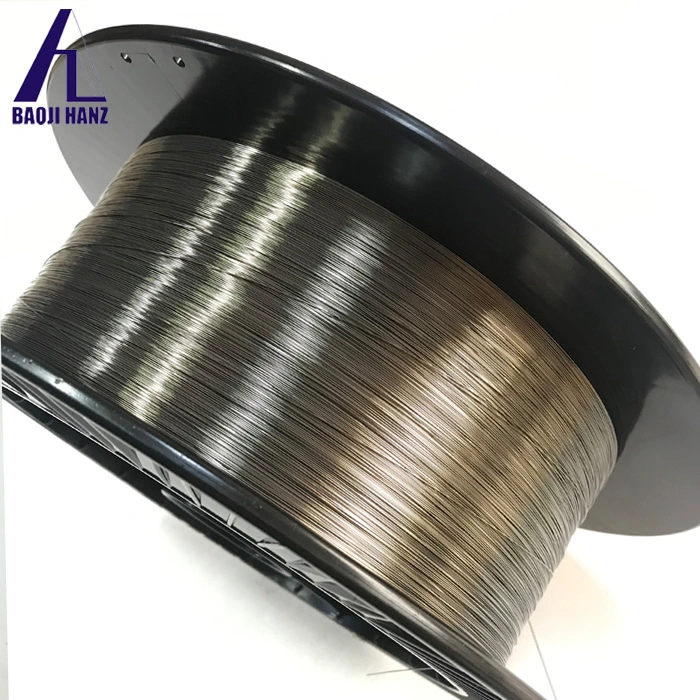

| Color | Black, brown, brown, blue, bright |

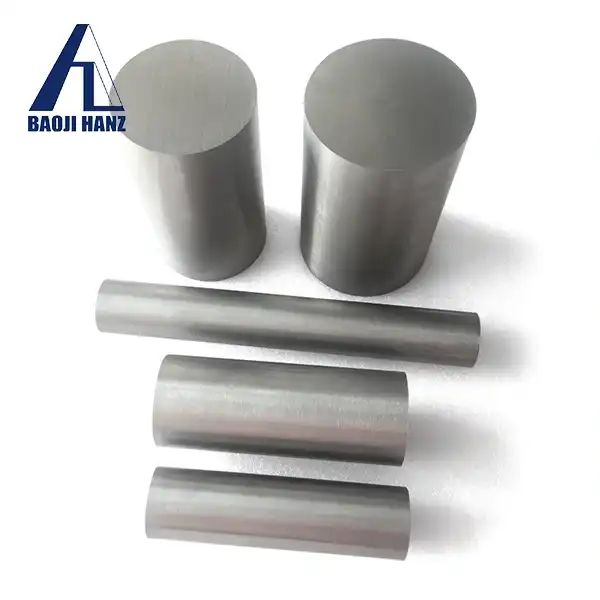

| Materials | Nitinol alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 45% |

| Strength | 980 Mpa |

| Processing Service | Bending, Welding, Decoiling |

| Wire Gauge | 0.02mm min |

| Tensile strength | 980 Mpa |

| Feature | Superelastic |

| Supply Status | Full annealed |

| Modulus of elasticity | Austenite 83 Gpa |

| The Max recovery stress | 185 MPa |

| Standard | ASTM F2063, Q/XB1516 |

| Certificate | ISO9001:2015 |

| Application | Guide wires Shape set parts ,Orthodontic Files .Arch wire . fishing wire .bra frames wire .glasses wire .spring wire |

| Chemical element | Af range | Available production Line | Usage | Sample |

| Nickel 55% Titanium 45% | 0℃to 100℃ | Rod&wire,Plate&sheet,Strip&foil | Medical&Industry | On stock (various specification) |

| Nickel 55% +V +Ti | ||||

| Nickel 55% +Fe +Ti | Subzero 30℃ to -5 ℃ | Rod&wire,Plate&sheet | Industry | On stock |

| Nickel 55%+Cr +Ti | (limitedspecification) | |||

| Nickel 55% +Hf +Ti | Above 100C | Ingot | Ingot | Updating |

| The production certification | ||||||

| Specification (mm) | Nitinol Superelastic wire | Typical Medical industry Application | ||||

| UTS (Mpa) | Elongation % | UpperPlateau Stress Mpa | Permanent Set after 6% strain % | Active AF | ||

| 0.1-0.3mm | ≥1100 | ≥15 | ≥480 | <0.5 | Subzero20~100 | Guide wires Shape set parts, orthodontic files, arch wire, fishing wire, bra frames wire, glasses wire,spring wire |

| 0.3~0.6mm | ≥920 | ≥15 | ≥440 | <0.5 | ||

| 0.6~3.0mm | ≥850 | ≥15 | ≥440 | <0.5 | ||

|

|

|

Application Areas

Our Astm F2063 nitinol wire superelastic finds extensive use across numerous industries due to its exceptional properties. Its primary application areas include:

- Medical Devices: Used in stents, guidewires, orthodontic archwires, and surgical instruments due to its biocompatibility and shape memory properties.

- Aerospace: Employed in actuators, valves, and deployable structures for its lightweight, corrosion-resistant, and fatigue-resistant characteristics.

- Automotive: Utilized in engine components, actuators, and fuel injection systems for its durability, shape memory, and resistance to high temperatures.

- Robotics: Integrated into robotic mechanisms, grippers, and sensors for its flexibility, resilience, and precise control.

Features

- Shape Memory: Recovers its original shape when heated after deformation, making it ideal for applications requiring precise positioning.

- Superelasticity: Exhibits high elasticity with minimal permanent deformation under stress, ensuring reliable performance in dynamic conditions.

- Biocompatibility: Suitable for medical implants and devices, minimizing the risk of adverse reactions in the human body.

- Corrosion Resistance: Withstands harsh environments, prolonging service life in aerospace and automotive applications.

- High Fatigue Resistance: Maintains structural integrity even after repeated stress cycles, ensuring long-term reliability.

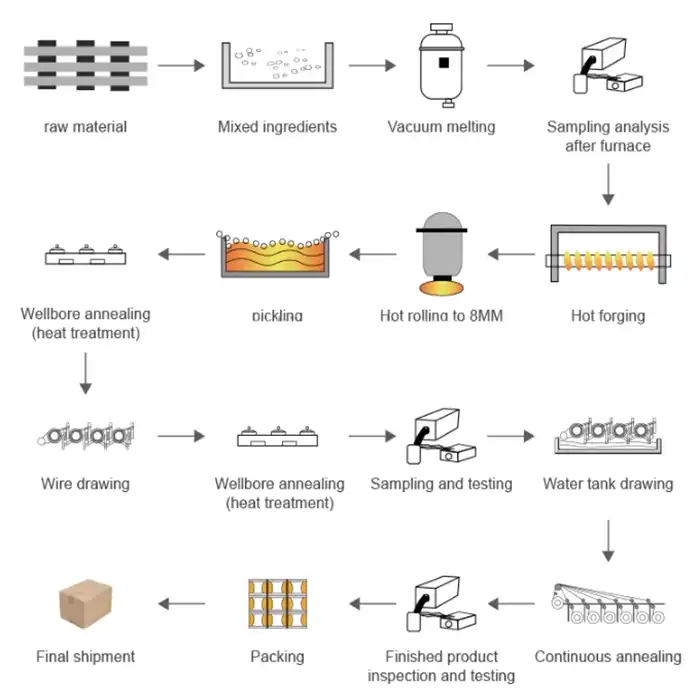

Production Technology

Our nitinol wire is manufactured using advanced processing techniques, including vacuum induction melting, hot rolling, cold drawing, and heat treatment, to achieve precise mechanical properties and dimensional accuracy. Stringent quality control measures are implemented throughout the production process to ensure conformance to ASTM F2063 standards and customer specifications.

Quality Control

At Baoji Hanz Metal Material Co., Ltd., quality is our main concern. We utilize a complete quality administration framework to screen each phase of creation, from unrefined substance obtainment to end result review. Our cutting edge testing offices and experienced specialists guarantee that each clump of it satisfies the best guidelines for execution, dependability, and security.

Company and equipment

Production process

Shipping

FAQs

-

What is ASTM F2063? ASTM F2063 is a standard specification for nickel-titanium shape memory alloy for medical devices and surgical implants.

-

Can nitinol wire be sterilized? Yes, the nitinol wire price can be sterilized using standard methods such as autoclaving, gamma radiation, or ethylene oxide.

-

What is the maximum operating temperature of nitinol wire? It can withstand temperatures up to approximately 500°C (932°F) without undergoing significant changes in its properties.

Final Details

Baoji Hanz Metal Material Co., Ltd. is an expert maker and provider of ASTM F2063 Nitinol Wire Superelastic with a devoted production line, broad stock, and complete certificates. With our obligation to quality and consumer loyalty, we offer quick and solid conveyance administrations around the world. For requests or to submit a request, please contact us at baojihanz-niti@hanztech.cn.

Send Inquiry

.webp)