What are nitinol guide wires made of?

2024-08-08 20:26:27

In the world of medical devices, nitinol guide wires play a crucial role in various diagnostic and interventional procedures. To fully appreciate their significance, it's important to understand what nitinol guide wires are made of, how their unique properties are leveraged, and why they are preferred in the medical field. This blog explores these aspects in depth, with a focus on the key components and properties of nitinol guide wires, and addresses some of the most commonly asked questions about them.

What Is Nitinol, and How Does It Affect Guide Wires?

Nitinol, an acronym for Nickel-Titanium Naval Ordnance Laboratory, is a nickel-titanium alloy known for its unique properties of shape memory and superelasticity. These properties make nitinol highly suitable for medical applications, particularly guide wires used in various procedures.

Nitinol guide wires are predominantly made from this alloy due to its distinctive characteristics. The alloy comprises approximately 50-55% nickel and 45-50% titanium. The exact ratio can be adjusted to fine-tune the material's properties for specific applications. The alloy's ability to "remember" its original shape and revert to it after deformation is what gives nitinol guide wires their name. This shape memory effect allows the guide wires to be flexible and resilient while maintaining their original form once they are in the desired position.

Nitinol's superelasticity is another crucial feature. When subjected to stress, nitinol can deform significantly and still return to its original shape when the stress is removed. This property enhances the maneuverability and durability of guide wires, making them ideal for navigating complex pathways within the body.

Why Are Nitinol Guide Wires Preferred in Medical Procedures?

Nitinol guide wires are favored in the medical field due to their unique combination of flexibility, strength, and biocompatibility. Let's delve into some of the reasons why nitinol guide wires are the go-to choice for medical professionals:

-

Flexibility and Maneuverability: The flexibility of nitinol allows guide wires to navigate through tortuous and narrow passages in the body with ease. This is essential for procedures such as catheterizations, angioplasties, and endoscopies, where precise navigation is crucial.

-

Shape Memory and Superelasticity: As mentioned earlier, nitinol's shape memory and superelasticity contribute to its effectiveness. These properties ensure that the guide wires can withstand bending and twisting forces without permanent deformation, maintaining their integrity and performance throughout the procedure.

-

Biocompatibility: Nitinol is highly biocompatible, meaning it is well-tolerated by the body and minimizes the risk of adverse reactions. This is a critical factor in medical applications, where minimizing patient risk is of utmost importance.

-

Strength and Durability: Despite its flexibility, nitinol is remarkably strong and durable. This combination of strength and flexibility ensures that the guide wires can endure the mechanical stresses encountered during procedures without breaking or losing functionality.

How Are Nitinol Guide Wires Manufactured?

The manufacturing process of nitinol guide wires involves several critical steps to ensure that the final product meets the required specifications and quality standards. Here's an overview of the process:

-

Material Preparation: The first step involves creating the nitinol alloy by combining nickel and titanium in precise proportions. The alloy is then melted and cast into the desired form, such as rods or wires.

-

Heat Treatment: Nitinol undergoes a heat treatment process to develop its shape memory and superelastic properties. This involves heating the alloy to a specific temperature and then cooling it in a controlled manner to establish the desired phase of the material.

-

Mechanical Processing: The heat-treated nitinol is then subjected to various mechanical processes, such as drawing, rolling, or extrusion, to achieve the required dimensions and properties. This step ensures that the guide wires have the necessary flexibility and strength.

-

Precision Shaping: The guide wires are further shaped and sized according to the specific requirements of their intended use. This involves processes like grinding, polishing, and coating to achieve the desired finish and performance characteristics.

-

Quality Control and Testing: Before the guide wires are released for medical use, they undergo rigorous quality control and testing to ensure they meet the necessary standards. This includes testing for flexibility, strength, biocompatibility, and overall performance.

What Are the Common Applications of Nitinol Guide Wires?

Nitinol guide wires are used in a variety of medical procedures, reflecting their versatility and effectiveness. Some common applications include:

-

Catheterization: Nitinol guide wires are frequently used in catheterization procedures, such as coronary catheterization, to navigate through blood vessels and reach specific locations within the body.

-

Angioplasty: In angioplasty procedures, nitinol guide wires help in positioning and advancing balloons or stents to open up blocked or narrowed blood vessels.

-

Endoscopy: During endoscopic procedures, nitinol guide wires assist in navigating the endoscope through the gastrointestinal tract or other internal passages.

-

Biopsy: Nitinol guide wires are used to guide biopsy needles to the target tissue for sampling.

-

Interventional Radiology: In interventional radiology, nitinol guide wires aid in the precise placement of various devices and instruments within the body.

How Do Nitinol Guide Wires Compare to Other Materials?

Nitinol guide wires offer several advantages over guide wires made from other materials, such as stainless steel or polymer-based materials. Here’s how nitinol stacks up:

-

Flexibility vs. Rigidity: Nitinol's flexibility and superelasticity surpass that of stainless steel, which is more rigid and less adaptable to complex anatomical pathways.

-

Shape Memory vs. Fixed Shape: Unlike traditional materials, nitinol’s shape memory allows it to return to its original form after deformation, which can be advantageous in maintaining performance during and after procedures.

-

Biocompatibility vs. Reactivity: Nitinol’s high biocompatibility reduces the risk of adverse reactions compared to materials that may be more reactive with the body's tissues.

-

Durability vs. Wear and Tear: Nitinol’s durability ensures that the guide wires can withstand the stresses of repeated use and complex procedures without losing their functional properties.

What Are the Future Trends in Nitinol Guide Wire Technology?

The field of medical device technology is constantly evolving, and nitinol guide wires are no exception. Some emerging trends and advancements include:

-

Enhanced Performance Characteristics: Research is ongoing to further enhance the performance characteristics of nitinol guide wires, such as improving their flexibility, strength, and biocompatibility.

-

Innovative Designs: New designs and configurations of nitinol guide wires are being developed to better address specific medical needs and procedural challenges.

-

Advanced Manufacturing Techniques: Advances in manufacturing techniques, such as additive manufacturing and precision machining, are being explored to create more sophisticated and tailored guide wires.

-

Integration with Imaging Technologies: There is growing interest in integrating nitinol guide wires with imaging technologies to provide real-time feedback and improve procedural accuracy.

About Baoji Hanz Metal Material Co., Ltd.

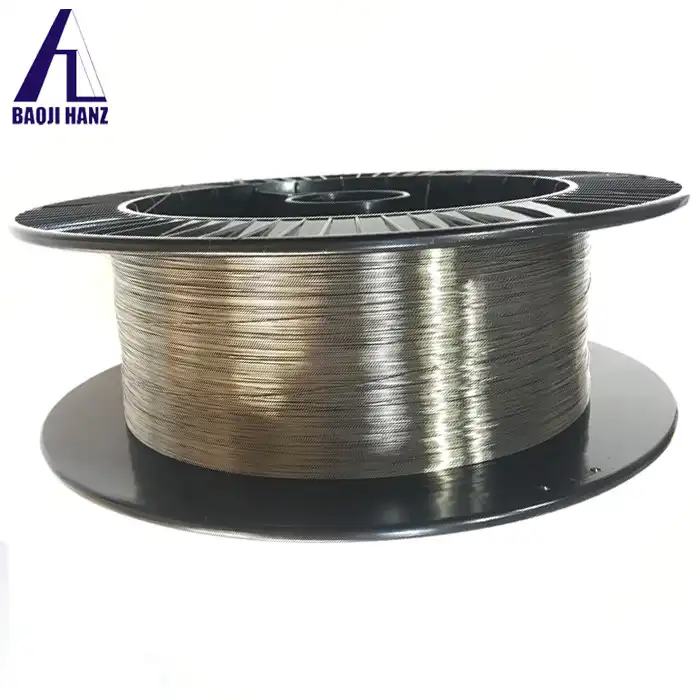

Baoji Hanz Metal Material Co., Ltd. is a leading provider of nitinol and other advanced metal materials. Established on November 15, 2017, and located in Baoji Titanium Valley Nonferrous Metals Base, China, the company is dedicated to delivering high-quality materials and solutions for various industrial and medical applications.

With a complete set of sophisticated production and processing equipment, Baoji Hanz Metal Material Co., Ltd. excels in the production of nitinol shape memory alloys, superelastic nitinol alloys, and nickel-titanium alloys. The company's focus on research and development, coupled with its advanced production and testing equipment, positions it as a leader in the field. Baoji Hanz is committed to advancing technology, ensuring excellent quality, and fostering win-win cooperation in all its business endeavors.

For more information about our products and services, please contact us at baojihanz-niti@hanztech.cn.

References

- "Nitinol Guide Wire Technology: Advances and Applications," Journal of Medical Devices, 2023.

- "Properties and Manufacturing of Nitinol Guide Wires," Biomedical Engineering Reviews, 2023.

- "Comparative Analysis of Guide Wire Materials," Medical Device Technology, 2024.

- "Innovations in Nitinol Guide Wire Design," Interventional Radiology Insights, 2023.