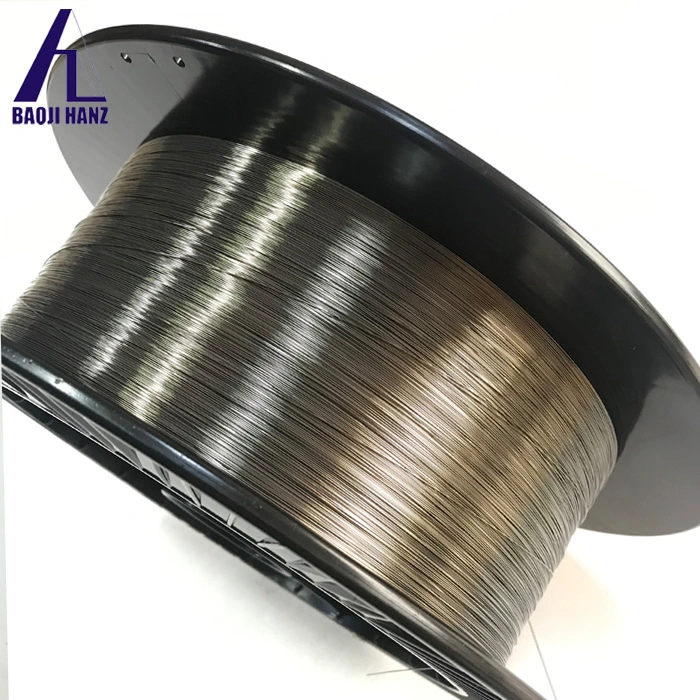

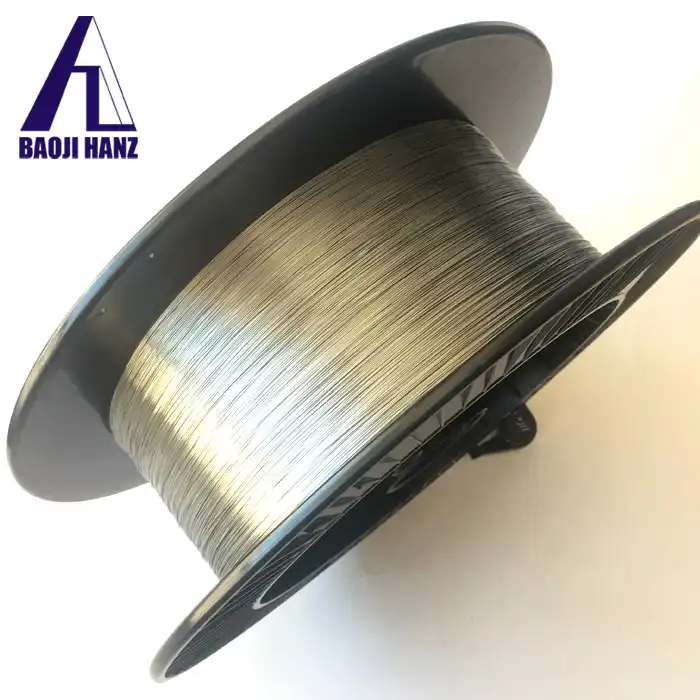

Product Details :

Our ASTM F2063 shape memory combination Nitinol wire is a flexible material with interesting properties that make it ideal for different applications. Made out of almost equivalent amounts of nickel and titanium, Nitinol displays the amazing skill to recollect its unique shape even after critical distortion. This wire is accessible in different breadths and lengths to suit assorted needs in businesses like clinical, aviation, car, and mechanical technology.

Features:

Shape memory property

Superelasticity

Biocompatibility

Corrosion resistance

High fatigue resistance

Specifications:

| Place of Origin | Shaanxi, China |

| Brand Name | Baoji hanz |

| Color | Black, brown, brown, blue, bright |

| Materials | Nitinol alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 45% |

| Strength | 980 Mpa |

| Processing Service | Bending, Welding, Decoiling |

| Wire Gauge | 0.02mm min |

| Tensile strength | 980 Mpa |

| Feature | Shape memory |

| Supply Status | Full annealed |

| Modulus of elasticity | Austenite 83 Gpa |

| The Max recovery stress | 185 MPa |

| Standard | ASTM F2063, Q/XB1516 |

| Certificate | ISO9001:2015 |

| Application | Guide wires Shape set parts ,Orthodontic Files .Arch wire . fishing wire .bra frames wire .glasses wire .spring wire |

●ASTM F2633-19 Standard specification for seamless Nickel-titanium memory tube fittings for Medical Devices and surgical implants

●ASTM F2005-05(2015) Standard term for Nickel-titanium shape memory alloys

●ASTM F2004-17(2017) Standard Test Method for Testing the Transition Temperature of Nitinol alloys by Thermal Analysis

● ASTM F2516-18 Tensile Test Method for Nickel-Titanium superelastic materials

●ASTM F2082/F2082M-16 Standard Test Method for Phase Change Temperature of Ni-Ti Shape Memory Alloys by bending and Free Recovery Methods

Chemical Composition List:

| Chemical element | Af range | Available production Line | Usage | Sample |

| Nickel 55% Titanium 45% | 0℃to 100℃ | Rod&wire,Plate&sheet,Strip&foil | Medical&Industry | On stock (various specification) |

| Nickel 55% +V +Ti | ||||

| Nickel 55% +Fe +Ti | Subzero 30℃ to -5 ℃ | Rod&wire,Plate&sheet | Industry | On stock |

| Nickel 55%+Cr +Ti | (limitedspecification) | |||

| Nickel 55% +Hf +Ti | Above 100C | Ingot | Ingot | Updating |

| Element | Mass Percent(Mass%) |

| Ni | 54.5~57.0 |

| C | ≤0.040 |

| Co | ≤0.050 |

| Cu | ≤0.010 |

| Cr | ≤0.010 |

| H | ≤0.005 |

| Fe | ≤0.050 |

| Nb | ≤0.025 |

| N | ≤0.005 |

| O | ≤0.040 |

| Ti | margin |

| The production certification | ||||||

| Specification (mm) | Shape Memory Nitinol wire | Typical Medical industry Application | ||||

| UTS (Mpa) | Elongation % | UpperPlateau Stress Mpa | Permanent Set after 6% strain % | Active AF | ||

| 0.1-0.3mm | ≥1100 | ≥15 | ≥480 | <0.5 | Subzero20~100 | Guide wires Shape set parts, orthodontic files, arch wire, fishing wire, bra frames wire, glasses wire,spring wire |

| 0.3~0.6mm | ≥920 | ≥15 | ≥440 | <0.5 | ||

| 0.6~3.0mm | ≥850 | ≥15 | ≥440 | <0.5 | ||

|

|

Application Areas :

Nitinol buy wire tracks down broad application in different fields because of its one of a kind properties. In the clinical area, it is generally utilized in negligibly obtrusive surgeries like stent sending, orthodontic supports, and catheterization. Its biocompatibility and shape memory make it especially appropriate for these applications. In aviation and car businesses, Nitinol wire is used for actuators, valves, and motor parts because of its lightweight nature and capacity to endure high temperatures and consumption. Furthermore, in advanced mechanics, Nitinol wire fills in as fake muscles for delicate advanced mechanics, considering exact and adaptable developments.

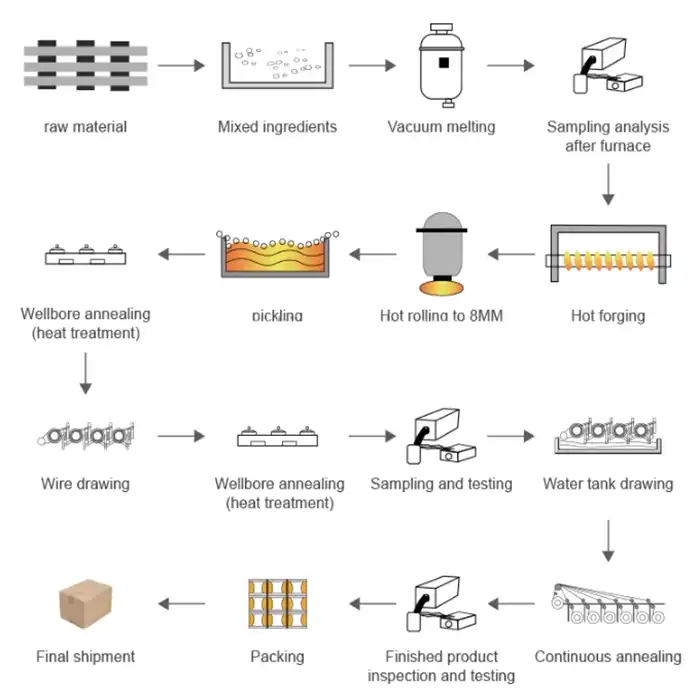

Production Technology:

Our medical grade nitinol wire memori goes through a thorough assembling process that integrates progressed procedures to guarantee the material's remarkable quality and execution. The interaction starts with vacuum enlistment liquefying, an exact strategy used to make an unadulterated and homogeneous combination. This underlying step is critical in laying out the establishment for the material's mechanical properties.

Accordingly, hot rolling is utilized to shape the Nitinol combination into the ideal structure, trailed by cool attracting to additionally refine its aspects and upgrade its mechanical strength. These cycles are carefully controlled to accomplish the expected degrees of consistency and consistency in the wire's properties.

The last stage includes heat treatment, where the Nitinol wire goes through painstakingly controlled warm handling to improve its shape memory and superelastic attributes. This basic step guarantees that the wire displays solid and reliable way of behaving, making it appropriate for a large number of utilizations.

By coordinating these high level handling procedures, including vacuum enlistment softening, hot rolling, cold drawing, and intensity therapy, we can certainly ensure the material's extraordinary mechanical properties and layered precision. This obligation to accuracy and quality highlights our commitment to giving elite execution nitinol buy wire to our clients' particular necessities.

Quality Control:

We adhere to strict quality control measures throughout the medical grade nitinol wire memori process to ensure the highest quality Nitinol wire. Our products undergo rigorous testing for mechanical properties, dimensional accuracy, surface finish, and chemical composition to meet ASTM F2063 standards.

Company and equipment

Production Pprocess:

Shipping:

Company and equipment:

FAQs:

-

What is the maximum deformation Nitinol wire can withstand?

- Nitinol wire can typically withstand up to 8% deformation before returning to its original shape.

-

Is Nitinol wire suitable for biomedical implants?

- Yes, Nitinol wire is widely used in biomedical implants due to its biocompatibility and shape memory properties.

-

Can Nitinol wire be customized according to specific requirements?

- Yes, we offer customized solutions for Nitinol wire diameter, length, and surface finish to meet individual needs.

Final Details:

Baoji Hanz Metal Material Co., Ltd. is an expert maker and provider of ASTM F2063 shape memory composite Nitinol wire. With our processing plant, enormous stock, complete authentications, and quick conveyance, we are focused on giving top notch Nitinol wire to worldwide purchasers and vendors.For inquiries or nitinol wire price per pound, please contact us at baojihanz-niti@hanztech.cn.

This professionally crafted Nitinol wire introduction aims to provide essential information to potential buyers and dealers, highlighting the product's features, applications,nitinol wire price per pound and quality assurance measures.

Send Inquiry

_1740043052871.webp)

.webp)