What is a super elastic nitinol sheet used for?

2024-09-27 19:54:22

Super elastic nitinol sheets are a remarkable material with a wide range of applications across various industries. These sheets, made from a nickel-titanium alloy, possess unique properties that make them invaluable in medical devices, aerospace engineering, and consumer electronics. Their ability to undergo significant deformation and return to their original shape without permanent damage has revolutionized product design and functionality. This blog post delves into the fascinating world of super elastic nitinol sheets, exploring their properties, applications, and the innovative ways they're being utilized to solve complex engineering challenges and improve everyday products.

Properties and Characteristics of Super Elastic Nitinol Sheets

Unique Shape Memory Effect

Super elastic nitinol sheets exhibit a remarkable shape memory effect, allowing them to return to their original form after significant deformation. This property stems from the material's crystalline structure, which undergoes a reversible phase transformation when subjected to stress or temperature changes. The shape memory effect enables nitinol sheets to "remember" their pre-programmed shape, making them ideal for applications requiring controlled, repeatable movements.

Exceptional Elasticity and Flexibility

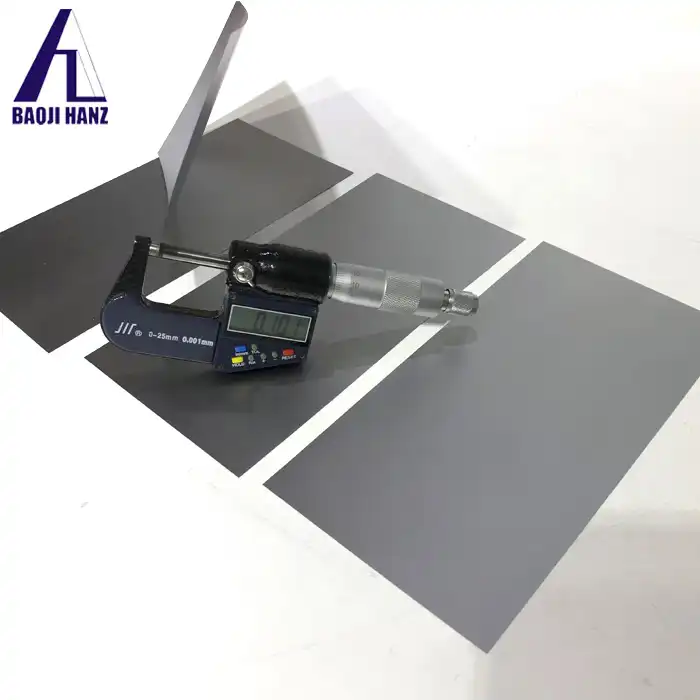

One of the most striking features of super elastic nitinol sheets is their extraordinary elasticity. These sheets can undergo strains of up to 8% without permanent deformation, far surpassing the capabilities of conventional metals. This exceptional flexibility allows for the creation of compact, lightweight structures that can withstand substantial bending and twisting forces without failing. The material's ability to absorb and distribute stress evenly contributes to its durability and resistance to fatigue.

Biocompatibility and Corrosion Resistance

Super elastic nitinol sheets boast excellent biocompatibility, making them a preferred choice for medical implants and devices. The material's resistance to corrosion in bodily fluids and its non-toxic nature ensure long-term stability within the human body. Additionally, nitinol's ability to form a protective oxide layer on its surface further enhances its corrosion resistance, extending the lifespan of devices and reducing the risk of adverse reactions in medical applications.

Applications of Super Elastic Nitinol Sheets in Various Industries

Medical Devices and Implants

The medical field has embraced super elastic nitinol sheets for their unique properties, leading to groundbreaking advancements in minimally invasive procedures and implantable devices. Cardiovascular stents, one of the most notable applications, utilize nitinol's shape memory and superelasticity to expand and support blood vessels. These stents can be compressed into a small diameter for insertion and then expand to their pre-programmed shape once in place, providing crucial support to weakened arteries. Orthodontic archwires made from nitinol sheets offer consistent, gentle forces for tooth movement, improving patient comfort and treatment efficiency.

Aerospace and Automotive Engineering

In the aerospace and automotive industries, super elastic nitinol sheets find applications in vibration damping and noise reduction systems. The material's ability to absorb and dissipate energy makes it ideal for creating adaptive structures that can change shape in response to varying environmental conditions. Nitinol-based actuators and sensors are used in aircraft control surfaces and automotive suspension systems, enhancing performance and efficiency. The lightweight nature of nitinol sheets also contributes to fuel efficiency and overall vehicle performance.

Consumer Electronics and Wearable Technology

The consumer electronics sector has harnessed the potential of super elastic nitinol sheets to create more durable and flexible devices. Smartphone antennas made from nitinol can withstand repeated bending and twisting without losing their functionality. In wearable technology, nitinol sheets are used to create comfortable, form-fitting devices that can adapt to body movements. Smart clothing incorporating nitinol elements can change shape or provide targeted compression, offering innovative solutions for sports performance and medical monitoring.

Manufacturing and Processing Techniques for Super Elastic Nitinol Sheets

Precision Melting and Casting

The production of high-quality super elastic nitinol sheets begins with precision melting and casting techniques. Vacuum induction melting is commonly employed to ensure the purity and homogeneity of the nickel-titanium alloy. This process allows for precise control over the material composition, which is crucial for achieving the desired superelastic properties. Advanced casting methods, such as continuous casting or strip casting, are utilized to produce uniform, defect-free ingots that serve as the starting material for sheet production.

Hot and Cold Rolling Processes

Once the initial ingot is formed, super elastic nitinol sheets undergo a series of hot and cold rolling processes to achieve the desired thickness and surface quality. Hot rolling is performed at temperatures above the material's recrystallization point, allowing for significant reduction in thickness while maintaining the alloy's microstructure. Subsequent cold rolling operations further refine the sheet thickness and improve surface finish. These rolling processes are carefully controlled to maintain the material's superelastic properties and ensure uniform thickness across the sheet.

Heat Treatment and Shape Setting

The final step in producing super elastic nitinol sheets involves precise heat treatment and shape setting procedures. Heat treatment is crucial for optimizing the material's superelastic behavior by controlling the transformation temperatures and crystalline structure. Shape setting techniques allow manufacturers to program specific shapes into the nitinol sheets, enabling them to return to these predetermined forms after deformation. This process typically involves fixing the sheet in the desired shape and subjecting it to carefully controlled heating and cooling cycles, effectively "training" the material to remember its intended configuration.

Conclusion

Super elastic nitinol sheets have revolutionized product design across numerous industries, offering unparalleled flexibility, durability, and functionality. From life-saving medical devices to innovative consumer electronics, the applications of this remarkable material continue to expand, driving technological advancements and improving our daily lives. As research and development in nitinol technology progresses, we can anticipate even more exciting and transformative applications in the future. If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1. Duerig, T. W., & Pelton, A. R. (2014). Materials properties handbook: Titanium alloys. ASM International.

2. Otsuka, K., & Wayman, C. M. (Eds.). (1999). Shape memory materials. Cambridge University Press.

3. Miyazaki, S., Fu, Y. Q., & Huang, W. M. (Eds.). (2009). Thin film shape memory alloys: Fundamentals and device applications. Cambridge University Press.

4. Yahia, L. H. (Ed.). (2000). Shape memory implants. Springer Science & Business Media.

5. Lagoudas, D. C. (Ed.). (2008). Shape memory alloys: Modeling and engineering applications. Springer Science & Business Media.

6. Jani, J. M., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.