Product Details :

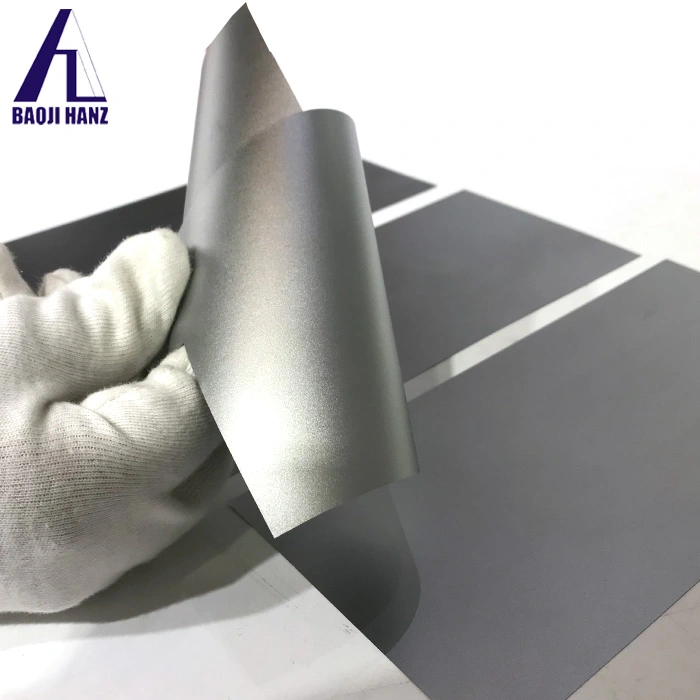

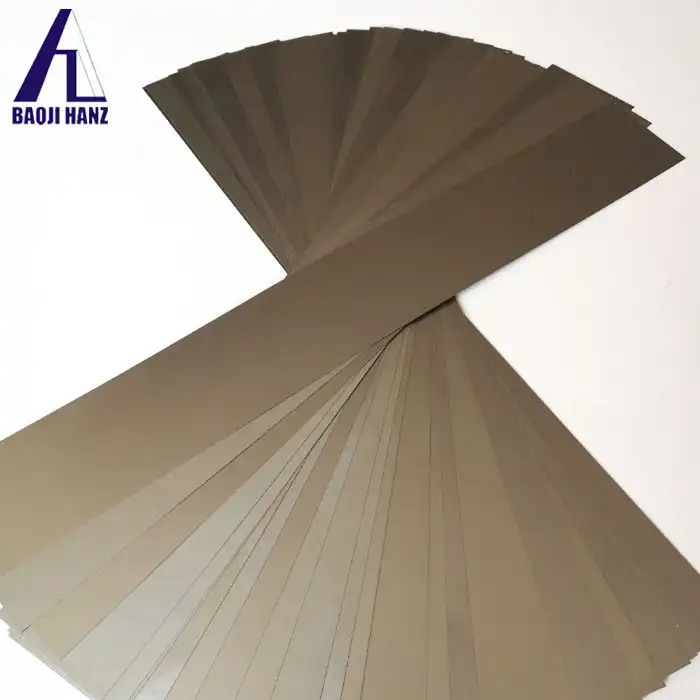

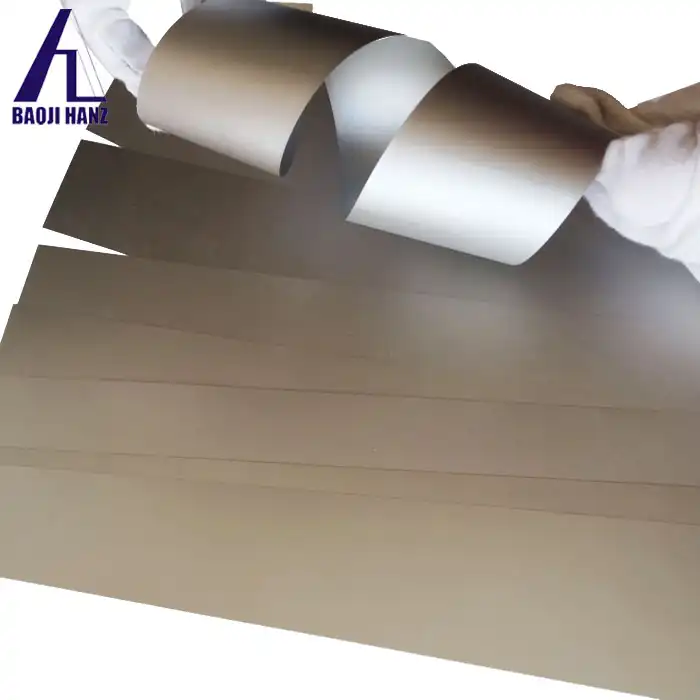

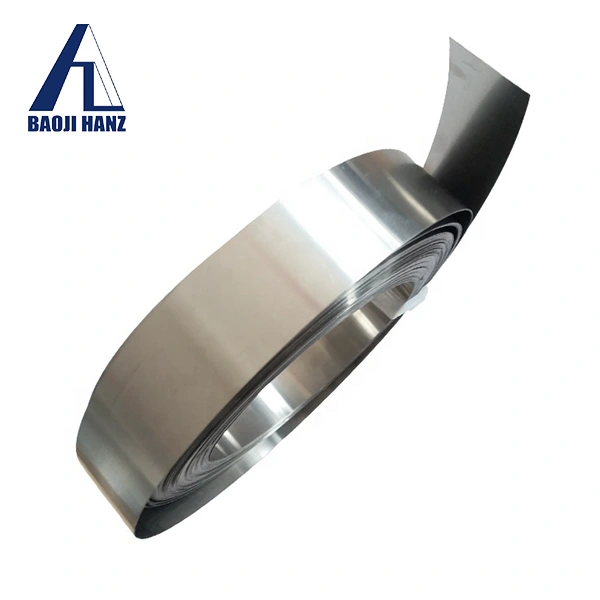

Our ASTM F2063 super elastic nitinol sheet, manufactured by Baoji Hanz Metal Material Co., Ltd., embodies cutting-edge technology and superior quality. With its remarkable piece of nickel and titanium, this sheet offers outstanding flexibility, durability, and biocompatibility. Meeting the severe prerequisites of ASTM F2063 principles, guaranteeing dependability and consistency in performance is fastidiously designed.

Specifications:

| Place of Origin | Shaanxi, China |

| Brand Name | Baoji hanz |

| Color | Bright surface |

| Materials | Nitinol alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 45% |

| Strength | 980 Mpa |

| Processing Service | Bending, Welding, Decoiling |

| Width | ≤200mm |

| Tensile strength | 920Mpa |

| Feature | Superelastic |

| Supply Status | Full annealed |

| The Max recovery stress | 600 MPa |

| Standard | ASTM F2063-18 |

| Certificate | ISO9001:2015 |

| Application | Medical device |

| Chemical element | Af range | Available production Line | Usage | Sample |

| Nickel 55% Titanium 45% | 0℃to 100℃ | Rod&wire,Plate&sheet,Strip&foil | Medical&Industry | On stock (various specification) |

| Nickel 55% +V +Ti | ||||

| Nickel 55% +Fe +Ti | Subzero 30℃ to -5 ℃ | Rod&wire,Plate&sheet | Industry | On stock |

| Nickel 55%+Cr +Ti | (limitedspecification) | |||

| Nickel 55% +Hf +Ti | Above 100C | Ingot | Ingot | Updating |

| Mechanical Properties | ||||

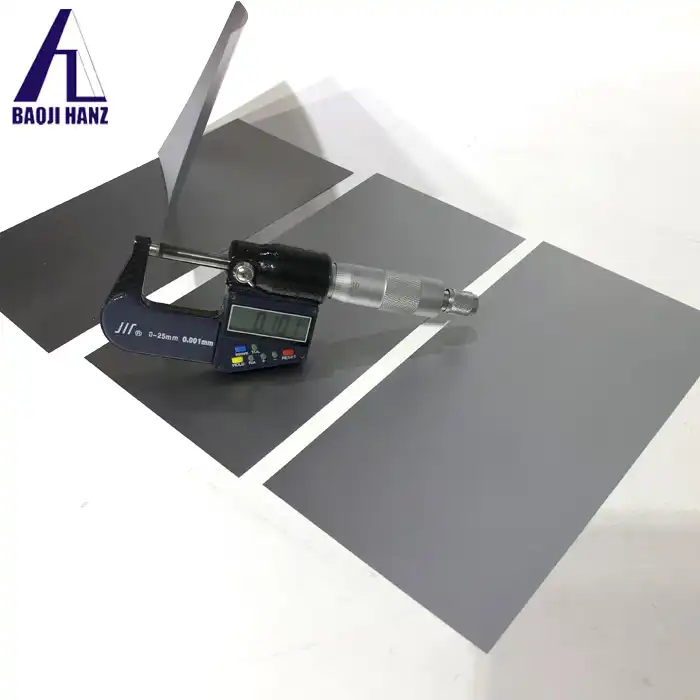

| Thickness | UTS | Elongation | Upper Plateau Stress | Active Af |

| mm | σb MPa (min.) | δ % (min) | σload MPa (min.) | ℃ |

| 0.1 ~ 0.3 | 1100 | 15 | 480 | |

| 0.3 ~ 0.6 | 920 | 15 | 440 | - 20 ~ 100 ℃ |

| 0.6 ~ 6.0 | 850 | 15 | 440 | |

| Tolerance | |

| Nominal Thickness in mm | Permissible Variation from Nominal in mm |

| 6.00 ~ 1.00 | ± 0.05 |

| 1.00 ~ 0.26 | ± 0.03 |

| 0.26 ~ 0.15 | ± 0.02 |

| 0.15 ~ 0.10 | ± 0.01 |

|

|

Application Areas :2

Our nitinol sheet metal finds diverse applications across various industries. In the medical field, it is extensively utilized for orthodontic wires, stents, and guidewires due to its biocompatibility and remarkable shape memory properties. Furthermore, it serves as an indispensable component in minimally invasive surgical instruments, ensuring precision and reliability in critical procedures.

In the aerospace and automotive sectors, our nitinol sheet is employed in actuators, dampers, and other intricate components where lightweight, high strength, and corrosion resistance are paramount. Its super elastic nature allows for efficient energy absorption and vibration damping, enhancing overall performance and safety.

Moreover, in the consumer electronics industry, our nitinol sheet plate is integrated into smart devices, such as mobile phones and wearable gadgets, for its shape memory capabilities, enabling innovative functionalities and compact designs.

Features:

- Exceptional elasticity and shape memory properties: These sheets exhibit outstanding elasticity, allowing them to withstand significant deformation without permanent shape changes. Moreover, they possess the shape memory effect, enabling them to revert to their original shape when subjected to specific temperatures. This makes them ideal for applications requiring resilience and precise shape control, such as medical devices and aerospace components.

- Biocompatible and corrosion-resistant: nitinol sheet metal are biocompatible, meaning they are viable with living tissue and don't cause antagonistic responses. This makes them reasonable for medical implants like orthopedic devices and cardiovascular stents. Also, they exhibit amazing corrosion resistance, guaranteeing sturdiness even in brutal conditions or when presented to destructive substances.

- Customizable dimensions for diverse applications:These sheets can be custom-made to meet explicit dimensional necessities, including thickness, width, and length. This flexibility takes into consideration exact customization to suit different application needs, furnishing designers with more noteworthy flexibility and versatility.

- Superior quality adhering to ASTM F2063 standards: Adhering to ASTM F2063 standards ensures that these Nitinol sheets meet stringent quality and safety requirements, particularly for medical applications. Manufacturers can rely on the consistency and reliability of these sheets, knowing that they comply with industry specifications.

Production Technology:

Our ASTM F2063 super elastic nitinol sheet is manufactured using state-of-the-art production techniques, including vacuum arc melting and hot rolling processes. These techniques guarantee exact command over piece, microstructure, and mechanical properties, bringing about predictable and solid execution.

Quality Control:

At Baoji Hanz Metal Material Co., Ltd., quality control is paramount. Our production processes are meticulously monitored and certified to meet international standards, including ASTM F2063. Each batch of nitinol sheet undergoes rigorous testing for composition, mechanical properties, and surface finish to ensure uncompromising quality and reliability.

FAQs:

- What is the composition of nitinol sheet plate ?

- It is basically made out of nickel and titanium, shaping an exceptional alloy known as nitinol.

- What are the main applications of nitinol sheet?

- Nitinol sheet is broadly utilized in clinical, aviation, auto, and consumer electronics industries for its amazing properties.

- Can the dimensions of nitinol sheet be customized?

- Yes, we offer customizable thickness, width, and length to suit specific application requirements.

Final Details:

Baoji Hanz Metal Material Co., Ltd. is a reputable manufacturer and supplier of ASTM F2063 super elastic nitinol sheet. With our advanced production facilities, large inventory, and comprehensive certificates, we ensure prompt delivery and unparalleled customer satisfaction. For inquiries or orders, please contact us at baojihanz-niti@hanztech.cn.

By adhering to ASTM F2063 standards and employing cutting-edge production techniques, we guarantee the highest quality and reliability in every nitinol sheet we deliver. Choose Baoji Hanz for your nickel titanium needs, and experience excellence in performance and service.

Send Inquiry

.webp)

_1740043052871.webp)