What is shape memory in Nitinol sheets?

2024-11-16 23:19:58

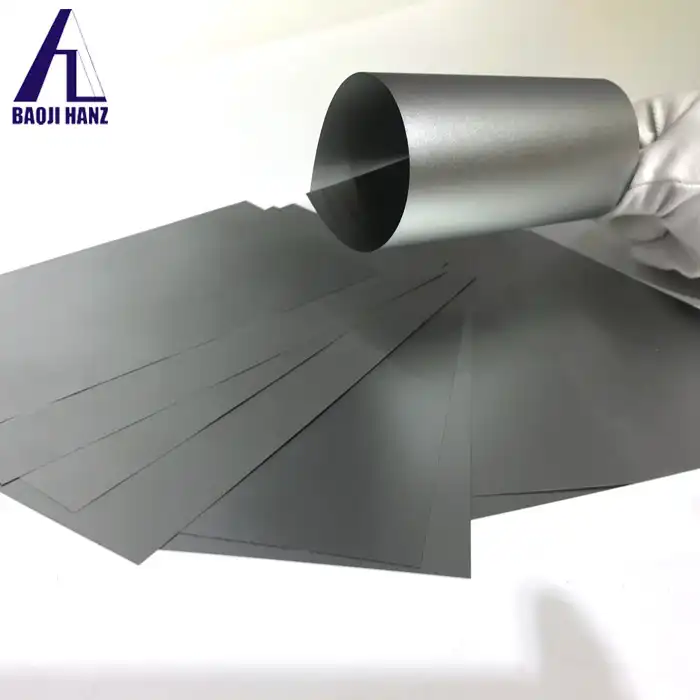

Shape memory nitinol sheet is a fascinating property that has revolutionized various industries, from medical devices to aerospace engineering. This unique characteristic allows Nitinol, an alloy of nickel and titanium, to "remember" and return to its original shape after being deformed. The shape memory effect in Nitinol sheets is attributed to their ability to undergo a reversible phase transformation between two crystal structures: austenite and martensite. This blog post delves into the intricacies of shape memory in Nitinol sheets, exploring their composition, working principles, applications, and the cutting-edge advancements in this field. Whether you're a materials scientist, engineer, or simply curious about this remarkable material, join us as we unravel the mysteries of shape memory Nitinol sheets.

The Science Behind Shape Memory Nitinol Sheets

Composition and Crystal Structure

Shape memory Nitinol sheets are composed of nearly equal atomic percentages of nickel and titanium. This precise composition is crucial for the material's unique properties. The crystal structure of Nitinol can exist in two distinct phases: austenite and martensite. Austenite is the high-temperature phase with a cubic crystal structure, while martensite is the low-temperature phase with a monoclinic crystal structure. The ability to transition between these phases is the key to Nitinol's shape memory effect.

Phase Transformation Mechanics

The shape memory effect in Nitinol sheets occurs due to a temperature-induced phase transformation. When a Nitinol sheet is cooled below its transformation temperature, it transitions from austenite to martensite. In this state, the material can be easily deformed. However, when heated above its transformation temperature, the Nitinol sheet reverts to its austenite phase, recovering its original shape. This phase transformation is reversible and can be repeated many times without significant degradation of the material's properties.

Stress-Induced Martensite

Another fascinating aspect of shape memory Nitinol sheet is their ability to form stress-induced martensite. This phenomenon occurs when stress is applied to the material in its austenitic state. The applied stress causes a portion of the austenite to transform into martensite, allowing for large, reversible strains. When the stress is removed, the material returns to its austenitic state and original shape. This property is known as superelasticity and is distinct from, but related to, the shape memory effect.

Applications of Shape Memory Nitinol Sheets

Medical Devices and Implants

Shape memory Nitinol sheets have found extensive applications in the medical field. Their biocompatibility and unique properties make them ideal for various medical devices and implants. Stents, which are used to keep arteries open, can be made from Nitinol sheets. These stents can be compressed into a small diameter for insertion and then expand to their predetermined shape once inside the artery. Orthodontic archwires, bone plates, and surgical instruments are other examples where shape memory Nitinol sheets are utilized to improve patient outcomes and simplify medical procedures.

Aerospace and Automotive Industries

The aerospace and automotive sectors have also embraced the potential of shape memory Nitinol sheets. In aircraft, Nitinol-based actuators can be used for noise reduction in jet engines, morphing airfoils, and vibration damping. The automotive industry utilizes Nitinol sheets in applications such as self-repairing car dents, adaptive headlight systems, and engine components that respond to temperature changes. The high fatigue resistance and ability to withstand extreme temperatures make shape memory Nitinol sheets particularly valuable in these demanding environments.

Consumer Electronics and Robotics

Shape memory Nitinol sheets have also made their way into consumer electronics and robotics. In smartphones, Nitinol actuators can be used for camera autofocus mechanisms and haptic feedback systems. The robotics field has embraced Nitinol sheets for creating flexible and adaptive structures, such as robotic grippers that can change shape to handle delicate objects. The material's ability to respond to electrical stimuli also opens up possibilities for creating smart textiles and wearable devices that can adapt to the user's body temperature or movements.

Advancements and Future Prospects of Shape Memory Nitinol Sheets

Improved Manufacturing Techniques

Recent advancements in manufacturing techniques have significantly enhanced the quality and consistency of shape memory Nitinol sheets. Precision melting and thermomechanical processing methods have been developed to control the alloy composition and microstructure more accurately. These improvements have led to Nitinol sheets with more predictable transformation temperatures and improved functional properties. Additionally, new techniques for creating ultra-thin Nitinol sheets have expanded the potential applications in miniaturized devices and microelectromechanical systems (MEMS).

Tailoring Transformation Temperatures

One of the most exciting areas of research in shape memory Nitinol sheets is the ability to tailor their transformation temperatures. By adjusting the nickel-titanium ratio and incorporating small amounts of other elements, researchers can fine-tune the temperature at which the shape memory effect occurs. This advancement allows for the creation of Nitinol sheets that respond to specific temperature ranges, opening up new possibilities in temperature-sensitive applications. For instance, shape memory Nitinol sheets with body temperature-activated transformations could revolutionize the design of implantable medical devices.

Hybrid and Composite Materials

The integration of shape memory Nitinol sheets with other materials is pushing the boundaries of what's possible with smart materials. Researchers are developing hybrid materials that combine Nitinol sheets with polymers, ceramics, or other metals to create composites with unique properties. These hybrid materials can exhibit enhanced strength, improved biocompatibility, or even multifunctional capabilities. For example, Nitinol-polymer composites are being explored for creating self-healing structures that can repair damage autonomously. The development of these advanced materials is opening up new avenues for innovation across various industries.

Conclusion

Shape memory nitinol sheets represents a remarkable feat of materials science, offering a wide range of applications across diverse industries. As research continues to advance, we can expect to see even more innovative uses for this extraordinary material in the future. If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1. Otsuka, K., & Wayman, C. M. (Eds.). (1999). Shape Memory Materials. Cambridge University Press.

2. Lagoudas, D. C. (Ed.). (2008). Shape Memory Alloys: Modeling and Engineering Applications. Springer Science & Business Media.

3. Duerig, T., Pelton, A., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273-275, 149-160.

4. Sun, L., Huang, W. M., Ding, Z., Zhao, Y., Wang, C. C., Purnawali, H., & Tang, C. (2012). Stimulus-responsive shape memory materials: A review. Materials & Design, 33, 577-640.

5. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

6. Chluba, C., Ge, W., Lima de Miranda, R., Strobel, J., Kienle, L., Quandt, E., & Wuttig, M. (2015). Ultralow-fatigue shape memory alloy films. Science, 348(6238), 1004-1007.