Why is nitinol wire special?

2024-08-08 20:26:36

Nitinol wire, an extraordinary material with remarkable properties, stands out for its unique capabilities that set it apart from other alloys. This blog will delve into why Nitinol wire is special, with a particular focus on its application, versatility, and the science behind its exceptional behavior.

What Makes Nitinol Wire Unique?

The Composition and Properties of Nitinol

Nitinol, an alloy of nickel and titanium, derives its name from its composition (Nickel Titanium Naval Ordnance Laboratory). This material is renowned for two extraordinary properties: shape memory and superelasticity. Shape memory refers to the ability of Nitinol to return to its original shape after deformation when exposed to a specific temperature. Superelasticity, on the other hand, allows Nitinol to undergo significant strain without permanent deformation, returning to its pre-strained shape almost instantly.

The uniqueness of Nitinol wire lies in its atomic structure and phase transformation. Nitinol exhibits a reversible phase transformation between two solid phases: austenite and martensite. At higher temperatures, Nitinol exists in the austenite phase, which is stronger and has a more regular atomic arrangement. When cooled, it transforms into the martensite phase, which is more malleable. This transformation is key to its shape memory and superelastic properties.

Applications Beyond Ordinary

The distinct properties of Nitinol wire make it suitable for a wide range of applications. In the medical field, Nitinol is used in stents, guidewires, and orthodontic archwires. Its ability to change shape at body temperature and return to its pre-deformed state makes it invaluable in minimally invasive surgeries. Additionally, Nitinol's biocompatibility ensures it can be used safely within the human body without causing adverse reactions.

In the aerospace and automotive industries, Nitinol's superelasticity and high fatigue resistance are leveraged for various components that undergo cyclic loading. This includes couplings, actuators, and sensors, where Nitinol’s ability to sustain large deformations without permanent damage proves beneficial.

Innovation and Research

Continuous research and innovation are expanding the capabilities and applications of Nitinol wire. Advancements in processing techniques and the development of new Nitinol alloys are enhancing its properties and opening up new possibilities. Researchers are exploring ways to improve the efficiency of Nitinol actuators and sensors, making them more responsive and reliable for critical applications.

How Does Nitinol Wire Work in Medical Applications?

Shape Memory in Medical Devices

One of the most significant applications of Nitinol wire is in the medical field. Its shape memory property is particularly useful in the development of self-expanding stents and other implantable devices. For instance, a Nitinol stent can be compressed into a small diameter for insertion into the body and then expand to its original shape at body temperature, ensuring it fits perfectly within a blood vessel.

Orthodontics also benefit from Nitinol's shape memory. Nitinol archwires are used in braces to apply consistent pressure to teeth, guiding them into the desired position over time. The wire’s ability to return to its original shape after deformation ensures that the pressure remains constant, making the treatment more effective and reducing the need for frequent adjustments.

Superelasticity in Surgical Instruments

Nitinol's superelasticity is another key property that enhances its use in medical applications. This property allows surgical instruments made from Nitinol to be highly flexible yet strong. For example, guidewires used in minimally invasive surgeries can navigate through the body's complex and delicate structures without kinking or breaking. This flexibility, combined with the strength to withstand repeated use, makes Nitinol an ideal material for such instruments.

Biocompatibility and Safety

The biocompatibility of Nitinol is a crucial factor in its medical applications. Nitinol does not corrode or degrade inside the body, and it does not cause significant adverse reactions, making it safe for long-term implantation. This characteristic is essential for devices like stents and orthopedic implants, which need to remain functional within the body for extended periods.

What Are the Advantages of Using Nitinol Wire in Engineering?

Durability and Fatigue Resistance

In engineering applications, Nitinol wire is prized for its durability and fatigue resistance. Components made from Nitinol can withstand repeated mechanical stress without experiencing significant wear or permanent deformation. This makes Nitinol an excellent choice for components that undergo cyclic loading, such as actuators and couplings in aerospace and automotive systems.

Flexibility and Lightweight Properties

Nitinol’s superelasticity and lightweight nature contribute to its widespread use in engineering. Its flexibility allows for the creation of complex, movable structures that can endure significant deformations and return to their original shape. This is particularly useful in robotics, where Nitinol wires are used as actuators to mimic the movement of muscles, providing precise control and movement in robotic systems.

Innovation in Actuators and Sensors

Nitinol’s unique properties are driving innovation in the design of actuators and sensors. In robotics, Nitinol actuators provide smooth, controlled movement and can operate in a wide range of temperatures. This makes them suitable for applications in harsh environments, such as space exploration or underwater operations. In sensors, Nitinol’s sensitivity to temperature changes can be utilized to create highly accurate thermal sensors.

Cost and Efficiency

While Nitinol wire may be more expensive than some traditional materials, its longevity and performance can lead to cost savings over time. The reduced need for maintenance and replacement, coupled with its superior performance, makes Nitinol a cost-effective solution for many high-stress applications. Additionally, advances in manufacturing processes are gradually reducing the cost of Nitinol, making it more accessible for a broader range of applications.

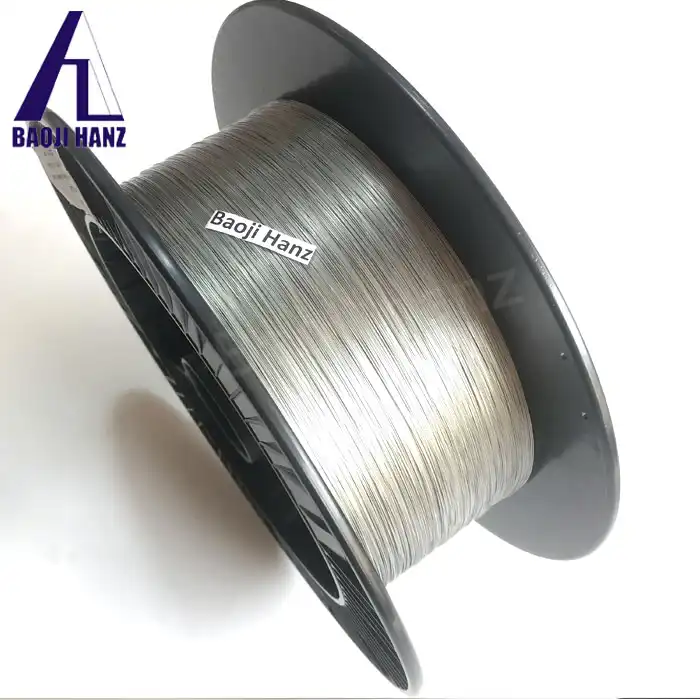

About Baoji Hanz Metal Material Co., Ltd.

Baoji Hanz Metal Material Co., Ltd., established on November 15, 2017, is located in Baoji Titanium Valley Nonferrous Metals Base in China. The company boasts a complete set of sophisticated production and processing equipment, excellent technology, and a professional sales and after-sales team. Our main business includes Nitinol shape memory alloy, superelastic Nitinol alloy, and nickel titanium alloy, as well as industrial furnace, mechanical equipment design, manufacturing, production, and service.

We pride ourselves on advanced R&D, production, and testing equipment, continuously committed to converting scientific research results and localizing imported products. Major projects completed by our company include high-purity metal material preparation, ultra-large and ultra-thin casting, and radiation generation and control material development. These projects have broadened new ideas for material purification, processing, and new material preparation, providing new markets and opportunities.

Baoji Hanz Metal Material Co., Ltd. wholeheartedly adopts the business philosophy of "leading technology, excellent quality, stable development, win-win cooperation." We are eager to work with colleagues from all walks of life to seize business opportunities and create a better future. For more information or inquiries, please contact us at baojihanz-niti@hanztech.cn.

References

-

Engineering Edge: "Understanding the Unique Properties of Nitinol"

-

Medical Device Network: "The Role of Nitinol in Modern Medical Devices"

-

Material Science: "Nitinol – A Shape Memory Alloy"

-

Journal of Biomedical Materials Research: "Nitinol's Biocompatibility and Medical Applications"

-

ASM International: "The Applications of Nitinol in Engineering"

-

Nature Materials: "Innovations in Nitinol Alloy Processing"

-

The Orthodontic Practice: "Advantages of Nitinol Archwires in Orthodontics"

-

Aerospace Manufacturing: "Nitinol in Aerospace Engineering"

-

Automotive Engineering: "Utilizing Nitinol in Automotive Components"

-

Robotics Today: "The Role of Nitinol in Robotics"