Product Details:

Our ASTM F2063 shape memory nitinol titanium flat wire is the consequence of fastidious designing and a promise to satisfying the most elevated guidelines of value and execution. Having remarkable flexibility and shape memory properties, settling on it a superb decision for many applications across different industries is explicitly planned.

The assembling system of our nitinol titanium level wire includes a cautious harmony between accuracy and mastery. Each wire is made with tender loving care, guaranteeing uniform aspects, predominant surface completion, and predictable mechanical properties. This degree of accuracy ensures that our level wire can flawlessly coordinate into perplexing plans and get through requesting conditions with amazing adaptability and solidness.

The outstanding adaptability of our nitinol titanium level wire gives fashioners and specialists unmatched opportunity in making complex shapes and designs. It tends to be handily bowed, turned, or shaped without losing its unique properties, making it exceptionally flexible for applications in clinical gadgets, aviation parts, purchaser hardware, and then some. Its capacity to hold its shape memory further improves its utility, permitting it to get back to its pre-characterized shape after deformity.

Also, the sturdiness of our level wire is unrivaled. It is designed to endure thorough use conditions and natural variables, making it profoundly dependable even in testing working conditions. Its consumption obstruction guarantees long haul execution and life span, going with it an ideal decision for basic applications where dependability is of most extreme significance.

In clinical gadgets, our level wire assumes a critical part in cutting edge careful devices, orthodontic machines, and cardiovascular inserts. Its adaptability empowers negligibly obtrusive techniques and exact intercessions, while its shape memory property considers modified fittings and worked on tolerant solace.

In aviation applications, our level wire adds to the improvement of lightweight parts, like actuators and control frameworks. Its outstanding flexibility and shape memory attributes guarantee ideal execution in requesting aviation conditions, upgrading unwavering quality and wellbeing.

In conclusion, our flat wire tracks down application in customer hardware, where its adaptability and sturdiness are fundamental for items like savvy wearables, cell phones, and electronic connectors. It empowers reduced and ergonomic plans while keeping up with dependable electrical associations.

All in all, our fastidiously designed wire nitinol flat sets the norm for quality and execution. With remarkable versatility, shape memory properties, adaptability, and strength, it succeeds in a great many applications across various businesses. Whether in clinical gadgets, aviation parts, or buyer hardware, our level wire reliably conveys predominant execution, empowering development, dependability, and proficiency in endless items and advances.

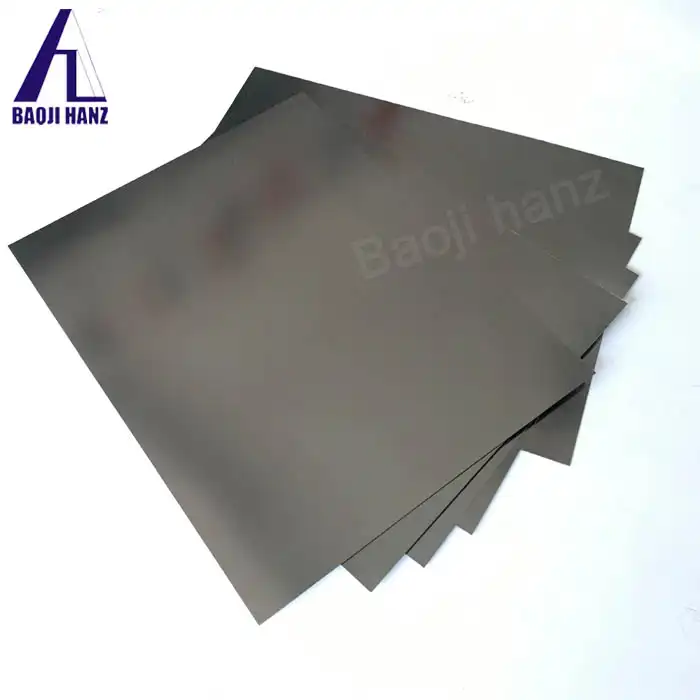

Specifications:

Our ASTM F2063 shape memory nitinol titanium flat wire is available in a range of sizes and dimensions to suit diverse application requirements. Refer to the table below for detailed specifications:

| Place of Origin | Shaanxi, China |

| Brand Name | Baoji hanz |

| Color | Black, brown, brown, blue, bright |

| Materials | Nitinol alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 45% |

| Strength | 980 Mpa |

| Processing Service | Bending, Welding, Decoiling |

| Wire Gauge | 0.02mm min |

| Tensile strength | 980 Mpa |

| Feature | Shape memory |

| Supply Status | Full annealed |

| Modulus of elasticity | Austenite 83 Gpa |

| The Max recovery stress | 185 MPa |

| Standard | ASTM F2063, Q/XB1516 |

| Certificate | ISO9001:2015 |

| Application | Guide wires Shape set parts ,Orthodontic Files .Arch wire . fishing wire .bra frames wire .glasses wire .spring wire |

| Chemical element | Af range | Available production Line | Usage | Sample |

| Nickel 55% Titanium 45% | 0℃to 100℃ | Rod&wire,Plate&sheet,Strip&foil | Medical&Industry | On stock (various specification) |

| Nickel 55% +V +Ti | ||||

| Nickel 55% +Fe +Ti | Subzero 30℃ to -5 ℃ | Rod&wire,Plate&sheet | Industry | On stock |

| Nickel 55%+Cr +Ti | (limitedspecification) | |||

| Nickel 55% +Hf +Ti | Above 100C | Ingot | Ingot | Updating |

| The production certification | ||||||

| Specification (mm) | Shape Memory Nitinol wire | Typical Medical industry Application | ||||

| UTS (Mpa) | Elongation % | UpperPlateau Stress Mpa | Permanent Set after 6% strain % | Active AF | ||

| 0.1-0.3mm | ≥1100 | ≥15 | ≥480 | <0.5 | Subzero20~100 | Guide wires Shape set parts, orthodontic files, arch wire, fishing wire, bra frames wire, glasses wire,spring wire |

| 0.3~0.6mm | ≥920 | ≥15 | ≥440 | <0.5 | ||

| 0.6~3.0mm | ≥850 | ≥15 | ≥440 | <0.5 | ||

Application Areas:

Our shape memory nitinol titanium flat wire finds extensive use across multiple industries, including:

- Medical: Surgical instruments, stents, orthodontic braces

- Aerospace: Actuators, deployable structures

- Automotive: Engine components, sensors

- Electronics: Micro actuators, sensors, antennas

With its exceptional versatility and reliability, our flat wire contributes to advancements in technology and enhances product performance across these sectors.

Features:

- Shape memory effect: Recovers original shape upon heating

- Superelasticity: Exhibits high flexibility and resilience

- Biocompatibility: Suitable for medical implants

- Corrosion resistance: Maintains integrity in harsh environments

- High fatigue resistance: Withstands repetitive deformation cycles

Production Technology:

The development of our level wire includes state of the art producing processes, integrating accuracy rolling and high flat intensity therapy strategies. At each phase of creation, fastidious consideration is given to observing and controlling the interaction to ensure consistency and severe adherence to the thorough ASTM F2063 guidelines.

In the underlying phases of assembling, the unrefined components go through severe quality checks to guarantee that they meet the demanding determinations expected for our flat wire. When the materials are endorsed, they continue to the accuracy moving stage. This basic step includes cautiously molding and shaping the unrefined components into the exact aspects and profiles determined for the flat wire. High flat hardware, combined with exact control frameworks, empowers us to accomplish consistency in aspects, guaranteeing that every flat wire fulfills the demanding guidelines set out by ASTM F2063.

Following the accuracy moving interaction, the level wire goes through a progression of intensity therapy strategies intended to upgrade its mechanical properties and shape memory qualities. Through controlled warming and cooling cycles, the wire's translucent design is unequivocally controlled to accomplish the ideal versatility and shape memory properties. Our cutting edge heat treatment procedures guarantee that the flat wire accomplishes the ideal harmony between adaptability and versatility, making it appropriate for a different cluster of utilizations across different enterprises.

All through the whole assembling process, severe quality control measures are executed to confirm that every level wire meets the predefined ASTM F2063 guidelines. Complete testing and examination conventions are utilized to survey basic credits like layered exactness, surface completion, mechanical properties, and shape memory conduct. Any deviation from the laid out norms prompts quick restorative activity, guaranteeing that main flat wire of the greatest quality is delivered for dissemination.

The obligation to accuracy and consistency in assembling is supported by our enduring devotion to maintaining the nitinol flat wire price. By sticking to these demanding prerequisites, we guarantee that our level wire reliably conveys extraordinary execution, unwavering quality, and strength across a wide range of uses.

In synopsis, our level wire is the result of state of the art fabricating processes, including accuracy rolling and high flat intensity therapy procedures, all painstakingly organized to maintain the rigid ASTM F2063 guidelines. From the fastidious determination of unrefined components to the last examination of completed items, each step is led with accuracy and greatness to convey flat wire of unmatched quality and execution.

Quality Control:

Stringent quality control measures are implemented throughout the manufacturing process to guarantee the reliability and performance of our flat wire. We conduct thorough inspections and tests to verify dimensional accuracy, mechanical properties, and surface finish.

FAQ:

1. What are the essential benefits of the product?

The essential benefits include shape memory, superelasticity, biocompatibility, and high corrosion resistance.

2. Can the dimensions of the flat wire be customized?

Yes, the thickness and width can be customized to meet specific requirements.

3. Is this flat wire suitable for biomedical applications?

Yes, it meets ASTM F2063 standards and is ISO 10993 tested for biocompatibility.

4. How does the shape memory property of this wire work?

The wire can return to its original shape after deformation when exposed to specific temperatures.

5. What certifications does the product hold?

The product holds ISO 13485, ASTM F2063, and RoHS compliance certifications.

Final Details:

Baoji Hanz Metal Material Co., Ltd. is a trusted manufacturer and supplier of ASTM F2063 shape memory nitinol titanium flat wire. With our advanced production facilities, extensive inventory, and comprehensive certifications, we are committed to meeting the diverse needs of our global clientele.

For inquiries or to place an order, please contact us at: baojihanz-niti@hanztech.cn. Choose Baoji Hanz for premium quality nitinol titanium wire and experience unparalleled reliability and customer service.

Send Inquiry

.webp)