Product Details:

Our ASTM F2063 Superelastic nitinol capillary tube are made with accuracy to fulfill the most noteworthy guidelines of value and execution. These cylinders display wonderful superelasticity, making them ideal for a great many clinical and modern applications. With prevalent adaptability and flexibility, our nitinol hairlike cylinders offer unrivaled unwavering quality in requesting conditions.

Specifications:

| Place of Origin | Shaanxi, China |

| Brand Name | Baoji hanz |

| Color | Bright |

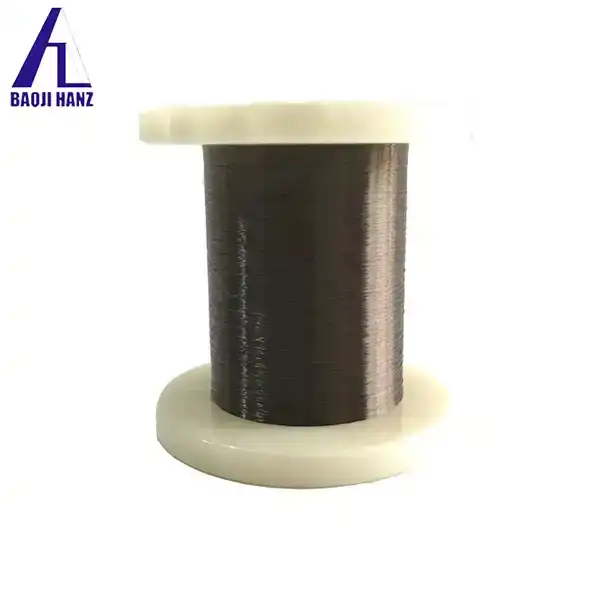

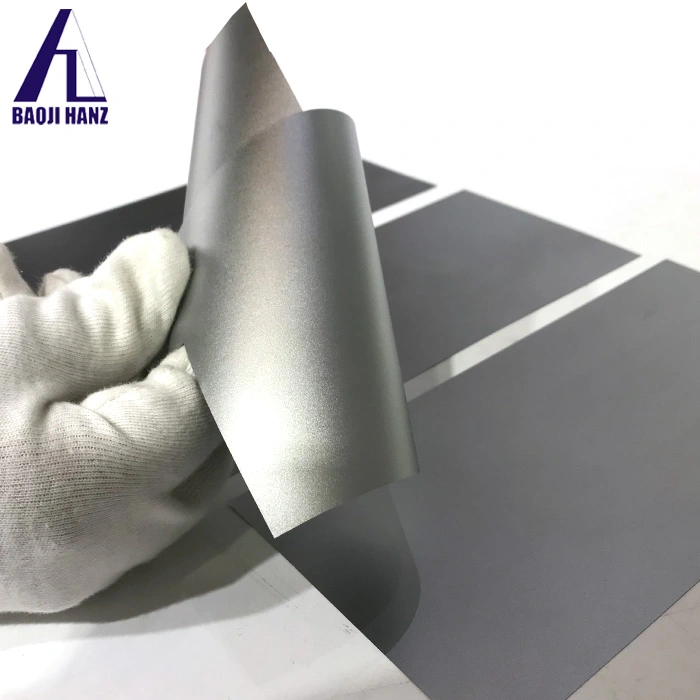

| Materials | Nitinol alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 45% |

| Processing Service | Bending, Decoiling, Cutting, Punching |

| Feature | Superelastic |

| Technique | Seamless |

| Shape | Round Shape |

| Supply Status | Annealling |

| The Max recovery stress | 1200Mpa |

| Standard | ASTM F2063-12/18 |

| Certificate | ISO9001:2015 |

| Application | Catheter / stents |

| Chemical element | Af range | Available production Line | Usage | Sample |

| Nickel 55% Titanium 45% | 0℃to 100℃ | Rod&wire,Plate&sheet,Strip&foil | Medical&Industry | On stock (various specification) |

| Nickel 55% +V +Ti | ||||

| Nickel 55% +Fe +Ti | Subzero 30℃ to -5 ℃ | Rod&wire,Plate&sheet | Industry | On stock |

| Nickel 55%+Cr +Ti | (limitedspecification) | |||

| Nickel 55% +Hf +Ti | Above 100C | Ingot | Ingot | updating |

|

|

Application Areas:

Our ASTM F2063 superelastic nitinol hairlike cylinders track down broad use in different fields, including:

Clinical Gadgets: These cylinders are generally utilized in negligibly obtrusive surgeries, like endoscopy, catheterization, and neurovascular mediations. Their superelasticity empowers exact route through perplexing physical designs.

Modern Applications: Nitinol hairlike cylinders are used in enterprises like aviation, car, and advanced mechanics for applications requiring lightweight, sturdy, and shape memory properties.

Electronics: These cylinders are utilized in the production of scaled down electronic parts, sensors, and actuators because of their high versatility and electrical conductivity.

Biomedical Exploration: Nitinol slender cylinders are used in lab settings for trial research in biomechanics, biomaterials, and tissue designing.

Features:

Superelasticity: Our nitinol tube manufacturers exhibit surprising superelasticity, meaning they can go through significant deformity and return to their unique shape without long-lasting harm. This special property makes them ideal for applications where adaptability and strength are fundamental, like in clinical gadgets and advanced mechanics.

Shape Memory: These Nitinol tubes have shape memory capacities, meaning they can "recollect" and return to a foreordained shape when exposed to warm. This component empowers them to adjust to different circumstances and keep up with their expected structure, making them appropriate for applications requiring perplexing plans and exact control, like stents and guidewires in negligibly obtrusive medical procedure.

Biocompatibility: Our Nitinol tubes agree with ASTM F2063 guidelines, guaranteeing they are biocompatible and alright for clinical implantation. This confirmation ensures that our cylinders limit the gamble of unfavorable responses or tissue dismissal when utilized in natural conditions, making them reasonable for a large number of clinical applications, including vascular inserts and muscular gadgets.

Erosion Obstruction: Nitinol's intrinsic consumption opposition guarantees the drawn out strength of our cylinders, even in brutal conditions or openness to destructive substances. This property improves the dependability and life expectancy of the cylinders, making them reasonable for applications in marine designing, aviation, and modern hardware where consumption is a worry.

Accuracy Designing: Our Nitinol tubes are made utilizing progressed creation innovation to guarantee exact aspects and uniform quality. Through fastidious control of the assembling system, we can ensure that each nitinol tube price per kg fulfills the strictest guidelines of exactness and consistency, empowering solid execution in requesting applications where accuracy is basic.

Production Technology:

Our ASTM F2063 Superelastic nitinol capillary tube go through creation through state of the art fabricating methods, including:

Vacuum Acceptance Liquefying (VIM): This cycle guarantees exact command over the substance creation of the composite, pivotal for keeping up with reliable material properties.

Hot Expulsion: Consistent cylinders are shaped with uniform microstructure and mechanical properties, fundamental for accomplishing solid execution.

Heat Treatment: This step upgrades the superelasticity and shape memory properties of the cylinders, streamlining their capacity to get back to their unique shape after deformity.

Accuracy Machining: Tight resistances and top notch surface completions are accomplished through accuracy machining, guaranteeing the cylinders satisfy demanding guidelines for layered precision and surface quality.

These high level assembling processes bring about Nitinol slim containers of remarkable quality and execution, ideal for a large number of uses in ventures like clinical gadgets, aviation, and mechanical technology.

Quality Control:

Quality is vital in our creation cycle. Our quality control measures include:

Substance Investigation to confirm arrangement adherence to ASTM F2063 norms.

Layered Assessment to guarantee exact nitinol tube manufacturers.

Mechanical Testing to approve superelastic and shape memory properties.

Visual Review for surface deformities and defects.

Discernibility all through the assembling system to keep up with item respectability.

FAQs:

What is superelasticity? Superelasticity alludes to the capacity of specific materials, for example, nitinol, to go through enormous reversible misshapenings and recuperate their unique shape after dumping.

Are nitinol narrow cylinders sterilizable? Indeed, our nitinol slim cylinders are viable with standard sanitization techniques, including autoclaving and ethylene oxide disinfection.

Might these cylinders at any point be tweaked? Indeed, we offer customization administrations to meet explicit layered and material prerequisites.

Final Details:

Baoji Hanz Metal Material Co., Ltd. is a main maker and provider of ASTM F2063 superelastic nitinol fine cylinders. With our high level creation offices, broad stock, and exhaustive accreditations, we are focused on giving predominant items and quick conveyance administrations. For requests or custom orders, kindly reach us at baojihanz-niti@hanztech.cn.

By picking Baoji Hanz Metal Material Co., Ltd., you're joining forces with a believed industry pioneer devoted to greatness in nitinol items.

Send Inquiry

.webp)

.webp)

.webp)

.webp)

.webp)