Product Overview:

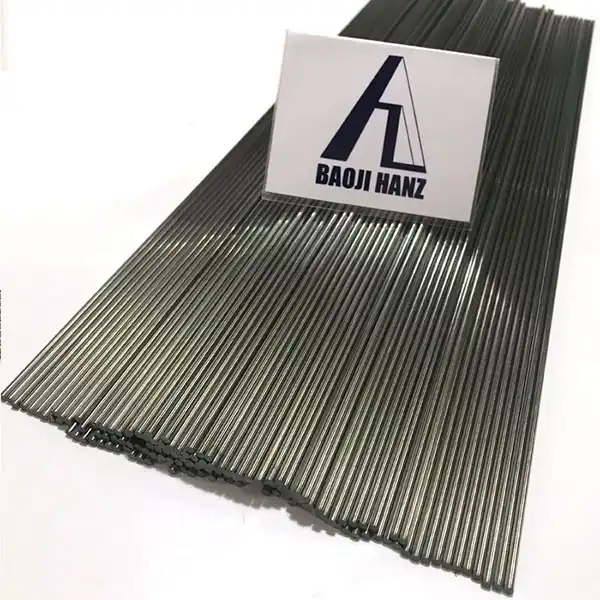

This Nitinol Shape Memory Alloy bar is a high-performance shape memory alloy (SMA) product known for its unique properties, including superelasticity and shape memory effects. Nitinol is composed of almost equal parts of nickel and titanium and has excellent mechanical and thermal properties.

Nitinol Shape Memory Alloy bar Execution Standards:

Nickel-titanium rods are typically manufactured according to standards such as ASTM F2063 (for surgical implants) or ASTM B348 (for general applications).

Features:

Superelasticity: allows significant deformation and full recovery after unloading.

Shape memory effect: When the heating temperature is higher than its deformation temperature, its original shape can be remembered and restored.

Biocompatibility: Suitable for medical applications due to compatibility with human tissues.

High damping capacity: Effective absorption and dissipation of energy, reducing vibration and noise.

Corrosion resistance: Corrosion resistance to various environments, including seawater and body fluids.

| Property | Value |

|---|---|

| Materials | Nickel (Ni): ~50%, Titanium (Ti): ~50% |

| Density | 6.45g/cm³ |

| Melting Point | 1240 - 1310°C |

| Transformation Temperature (Af) | Customizable (-20 to 110)°C |

| Tensile Strength | 754 - 960MPa |

| Elongation at Break | 15 - 20% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| MOQ | 1kg or 1meter |

Advantages of Nitinol Shape Memory Alloy bar:

Excellent performance: Provides superior mechanical and thermal properties for demanding applications.

Long service life: Excellent fatigue resistance and durability to ensure long-term use.

Design flexibility: Thanks to its unique shape memory and hyperelastic properties, innovative designs and functions can be achieved.

Ordering information:

Available in a variety of diameters and lengths.

Deformation temperature and mechanical properties can be customized according to specific requirements.

Application:

Medical equipment: stent, guide wire, orthodontic wire, surgical instrument, bone implant.

Actuators and sensors: Microactuators, temperature sensors, position sensors.

Automotive: Engine components, sensors, vibration control systems.

Consumer electronics: Glasses frames, cell phone antennas.

Aerospace. The coupling. The shock absorber. Deployable structure.

Packaging and transportation:

Company and equipment:

Other related product catalogues

Nickel titanium memory alloy in addition to the production of nickel-titanium strips, can also produce other similar products, such as nickel-titanium plate, nickel titanium flat wire, nickel titanium foil, nickel titanium wire, nickel titanium tube, nickel titanium spring, nickel titanium paper clips, nickel titanium wire rope.

|

|

|

|

|

|

|

|

FAQ:

1. What is the composition of nickel-titanium rod?

Nickel-titanium rods are typically composed of approximately 55% nickel and 45% titanium and are known for their shape memory and superelastic properties.

2. What are the main applications of Nitinol rods?

Due to their unique properties, they are widely used in medical devices, aerospace, robotics and actuators.

3. What is the temperature range of Ni-Ti rod shape memory effect?

Shape memory effects typically occur in the temperature range of -20°C to 80°C, depending on the specific alloy composition.

4. Are nickel-titanium rods corrosion-resistant?

Yes, they have excellent corrosion resistance, making them suitable for use in harsh environments, including medical and Marine applications.

5. Is Nitinol alloy rod easy to process?

No, they are difficult to process due to their superelasticity and hardness. Expertise such as EDM is usually required.

6. What is the life of the nickel-titanium rod?

They have a long fatigue life, often exceeding millions of cycles, making them ideal for applications that require repeated stress or movement.

Contact us:

For more information or to request a quote, please feel free to contact us at baojihanz-niti@hanztech.cn. Our team of experts is ready to help you find the perfect Nitinol solution for your application.

Send Inquiry

_1740042005804.webp)

_1730384983886.webp)