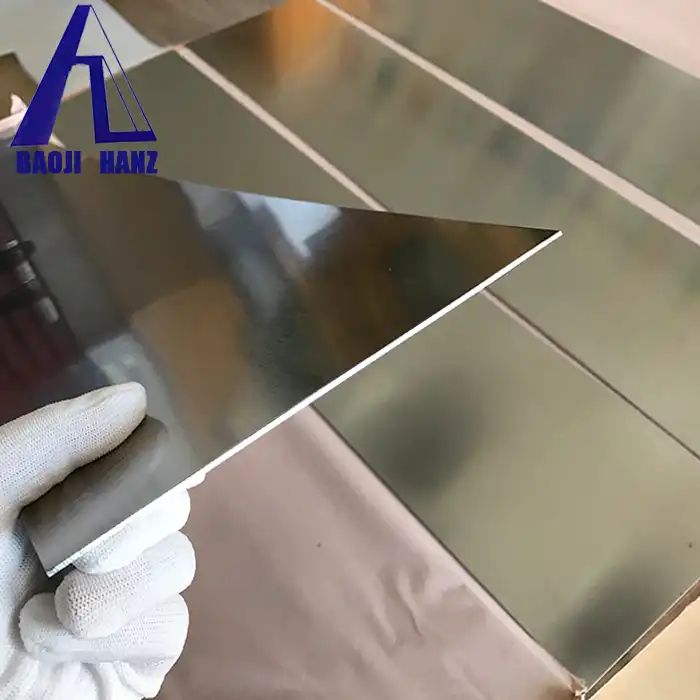

Product Introduction:

Product Details:Our ASTM F2063 Shape Memory Straight Nitinol Wire is a high-quality product manufactured to meet the stringent standards of ASTM F2063. It is composed of a unique nickel-titanium alloy, renowned for its exceptional shape memory properties and superelasticity. This wire exhibits the remarkable ability to return to its original shape upon heating, making it ideal for a wide range of applications in various industries.

Specifications

| Place of Origin | Shaanxi, China |

| Brand Name | Baoji hanz |

| Color | Black, brown, brown, blue, bright |

| Materials | Nitinol alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 45% |

| Strength | 980 Mpa |

| Processing Service | Bending, Welding, Decoiling |

| Wire Gauge | 0.02mm min |

| Tensile strength | 980 Mpa |

| Feature | Shape memory |

| Supply Status | Full annealed |

| Modulus of elasticity | Austenite 83 Gpa |

| The Max recovery stress | 185 MPa |

| Standard | ASTM F2063, Q/XB1516 |

| Certificate | ISO9001:2015 |

| Application | Guide wires Shape set parts ,Orthodontic Files .Arch wire . fishing wire .bra frames wire .glasses wire .spring wire |

| Chemical element | Af range | Available production Line | Usage | Sample |

| Nickel 55% Titanium 45% | 0℃to 100℃ | Rod&wire,Plate&sheet,Strip&foil | Medical&Industry | On stock (various specification) |

| Nickel 55% +V +Ti | ||||

| Nickel 55% +Fe +Ti | Subzero 30℃ to -5 ℃ | Rod&wire,Plate&sheet | Industry | On stock |

| Nickel 55%+Cr +Ti | (limitedspecification) | |||

| Nickel 55% +Hf +Ti | Above 100C | Ingot | Ingot | Updating |

| The production certification | ||||||

| Specification (mm) | Shape Memory Nitinol wire | Typical Medical industry Application | ||||

| UTS (Mpa) | Elongation % | UpperPlateau Stress Mpa | Permanent Set after 6% strain % | Active AF | ||

| 0.1-0.3mm | ≥1100 | ≥15 | ≥480 | <0.5 | Subzero20~100 | Guide wires Shape set parts, orthodontic files, arch wire, fishing wire, bra frames wire, glasses wire,spring wire |

| 0.3~0.6mm | ≥920 | ≥15 | ≥440 | <0.5 | ||

| 0.6~3.0mm | ≥850 | ≥15 | ≥440 | <0.5 | ||

|

|

|

Application Areas

Our Astm F2063 Superelastic Nitinol Straight Wire finds extensive usage across diverse industries. In the medical field, it is employed in minimally invasive surgical procedures such as endovascular treatments, where its superelasticity allows for precise navigation through blood vessels. Additionally, it is utilized in orthodontic braces, guiding archwires, and stents due to its biocompatibility and shape memory properties.

In the aerospace industry, our nitinol wire is utilized in actuators, deployable structures, and control systems owing to its lightweight nature and ability to withstand extreme conditions. Furthermore, it is utilized in robotics for applications requiring intricate movements and precise control.

Features

- Exceptional shape memory properties

- Superelasticity

- Biocompatibility

- High corrosion resistance

- Lightweight

- Durable

Production Technology

Our ASTM F2063 Shape Memory Straight Nitinol Wire is manufactured using advanced processing techniques, including vacuum induction melting, hot rolling, cold working, and heat treatment. These processes ensure the precise control of composition and microstructure, resulting in a product of consistent quality and performance.

Quality Control

At Baoji Hanz Metal Material Co., Ltd., we place utmost importance on quality control to deliver nitinol wire that meets the highest standards of excellence. Adhering strictly to the widely recognized 1mm straight nitinol wire, we implement robust quality control measures throughout the entire production process.

Rigorous testing and inspection are conducted at every stage to guarantee the superior quality and reliability of our nitinol wire. Starting with the selection of raw materials, we source only the finest titanium and nickel alloys from trusted suppliers who meet our stringent quality criteria. This ensures that the foundation of our nitinol wire is of exceptional quality.

During the manufacturing process, we employ cutting-edge techniques and advanced equipment to shape, heat-treat, and process the wire with precision. At each step, our experienced technicians conduct meticulous inspections to verify compliance with ASTM F2063 standards. This includes monitoring dimensional accuracy, mechanical properties, and surface finish to ensure consistency and reliability.

Dimensional accuracy is crucial in nitinol wire, especially for applications that require precise specifications. We employ state-of-the-art measurement tools and conduct thorough inspections to verify that the wire meets the specified tolerances. This guarantees that our customers receive a product that aligns perfectly with their requirements.

Mechanical properties testing is another critical aspect of our quality control process. Through comprehensive tests, we assess the wire's strength, elasticity, shape memory characteristics, and resistance to fatigue. By subjecting our nitinol wire to rigorous evaluations, we ensure that it performs reliably and consistently in demanding applications.

Surface finish inspections are conducted to maintain the high aesthetic standards expected from our nitinol wire. Our skilled inspectors employ visual examination techniques and specialized instruments to identify any imperfections, such as scratches or surface irregularities. This attention to detail ensures that our wire not only meets functional requirements but also satisfies the visual expectations of our customers.

Our commitment to quality control drives every aspect of our manufacturing process. From raw material selection to final inspection, we adhere strictly to ASTM F2063 standards, conducting rigorous testing and inspections to guarantee the highest quality and reliability of our nitinol wire. By upholding these stringent quality control measures, we aim to exceed customer expectations and deliver products that excel in performance and durability.

FAQs

1. What are the essential benefits of the product?

The essential benefits include shape memory, superelasticity, high strength, and biocompatibility.

2. Can the wire be customized for specific transformation temperatures?

Yes, the transformation temperature can be customized to meet specific application requirements.

3. Is this wire suitable for use in medical devices?

Yes, it meets ASTM F2063 standards and is ISO 10993 tested for biocompatibility.

4. How does the superelasticity of this wire compare to conventional materials?

The wire can recover its original shape after significant deformation, unlike conventional materials.

5. What certifications does the product hold?

The product holds ISO 13485, ASTM F2063, and RoHS compliance certifications.

Final Details

Baoji Hanz Metal Material Co., Ltd. is a leading manufacturer and supplier of ASTM F2063 Shape Memory Straight Nitinol Wire. With our state-of-the-art factory, large inventory, and complete certificates, we guarantee fast delivery and exceptional customer service. For inquiries or to place an order, please contact us at baojihanz-niti@hanztech.cn.

Send Inquiry

.webp)

.webp)

.webp)

.webp)

_1740043052871.webp)