Product Details :

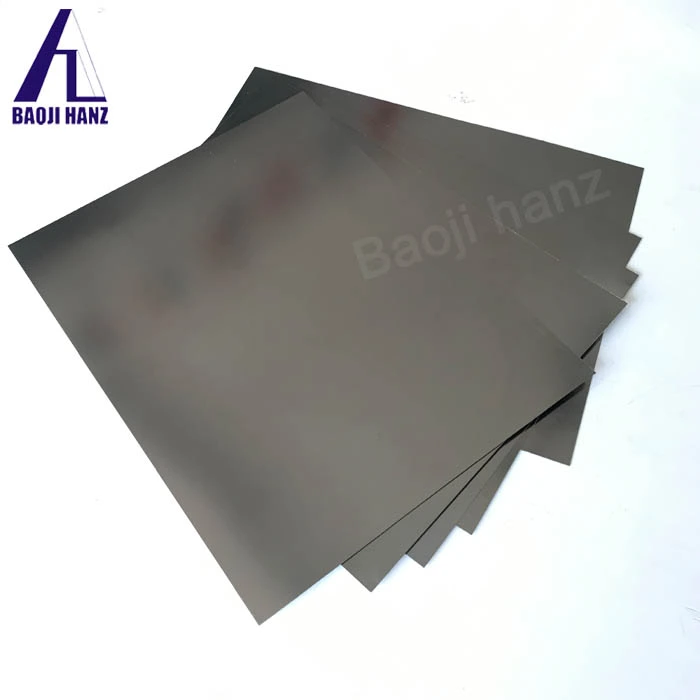

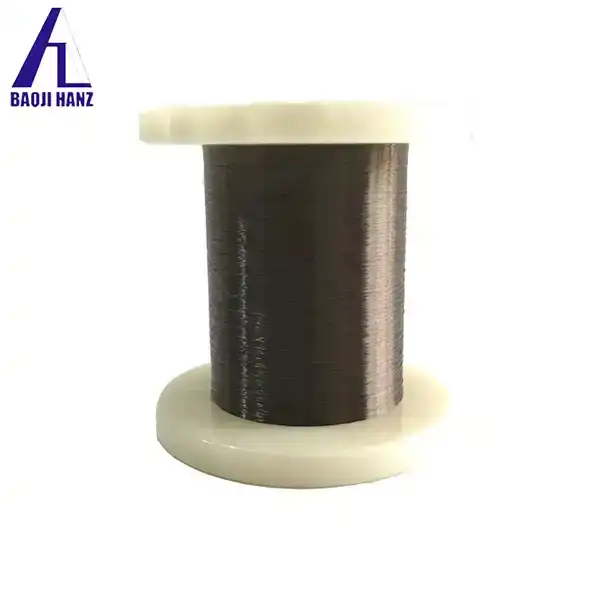

Our nitinol wire medical product, manufactured by Baoji Hanz Metal Material Co., Ltd., leverages the exceptional properties of Nitinol, a shape memory alloy composed of nickel and titanium. This versatile material exhibits unique characteristics such as superelasticity and shape memory, which are critical for various medical applications. The superelasticity of Nitinol allows it to undergo significant deformation and then return to its original shape, making it invaluable in medical devices that require flexibility and durability.

Our nitinol wire niti is meticulously crafted to meet the demanding standards of the medical industry, ensuring unparalleled reliability and performance in surgical procedures and medical devices. Its biocompatibility and consumption obstruction make it especially appropriate for inserts and other long haul clinical applications.For instance, Nitinol wire is used in the fabrication of stents, guidewires, and orthodontic archwires, where its ability to conform to and support anatomical structures is essential.

Baoji Hanz Metal Material Co., Ltd. employs precise engineering and stringent quality control measures to ensure that our product consistently meets high-performance criteria. Thusly, we furnish clinical experts with items that upgrade patient results and add to the headway of clinical innovation. Our commitment to quality and innovation ensures that our prodduct remains a trusted choice in the medical industry.

Specifications:

| Place of Origin | Shaanxi, China |

| Brand Name | Baoji hanz |

| Color | Black, brown, brown, blue, bright |

| Materials | Nitinol alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 45% |

| Strength | 980 Mpa |

| Processing Service | Bending, Welding, Decoiling |

| Wire Gauge | 0.02mm min |

| Tensile strength | 980 Mpa |

| Feature | Superelastic |

| Supply Status | Full annealed |

| Modulus of elasticity | Austenite 83 Gpa |

| The Max recovery stress | 185 MPa |

| Standard | ASTM F2063, Q/XB1516 |

| Certificate | ISO9001:2015 |

| Application | Guide wires Shape set parts ,Orthodontic Files .Arch wire . fishing wire .bra frames wire .glasses wire .spring wire |

| Chemical element | Af range | Available production Line | Usage | Sample |

| Nickel 55% Titanium 45% | 0℃to 100℃ | Rod&wire,Plate&sheet,Strip&foil | Medical&Industry | On stock (various specification) |

| Nickel 55% +V +Ti | ||||

| Nickel 55% +Fe +Ti | Subzero 30℃ to -5 ℃ | Rod&wire,Plate&sheet | Industry | On stock |

| Nickel 55%+Cr +Ti | (limitedspecification) | |||

| Nickel 55% +Hf +Ti | Above 100C | Ingot | Ingot | Updating |

| The production certification | ||||||

| Specification (mm) | Nitinol Superelastic wire | Typical Medical industry Application | ||||

| UTS (Mpa) | Elongation % | UpperPlateau Stress Mpa | Permanent Set after 6% strain % | Active AF | ||

| 0.1-0.3mm | ≥1100 | ≥15 | ≥480 | <0.5 | Subzero20~100 | Guide wires Shape set parts, orthodontic files, arch wire, fishing wire, bra frames wire, glasses wire,spring wire |

| 0.3~0.6mm | ≥920 | ≥15 | ≥440 | <0.5 | ||

| 0.6~3.0mm | ≥850 | ≥15 | ≥440 | <0.5 | ||

|

|

|

|

Application Areas:

Our nitinol wire medical use in various clinical fields because of its uncommon properties. It is regularly utilized in negligibly obtrusive medical procedures, orthodontics, vascular mediations, from there, the sky is the limit. In orthodontics, they are used for dental supports because of their capacity to apply steady, delicate power for tooth arrangement. Inside vascular mediations, it goes about as a structure for stents, giving adaptability and flexibility to vessel shapes. Furthermore, it fills in as a significant part in different careful instruments, for example, guide wires and recovery gadgets, working with exact and compelling systems. The flexibility of super elastic nitinol medic wire stretches out to nervous system science, where it supports the treatment of aneurysms and other neurological circumstances. Its biocompatibility and consumption opposition make it an irreplaceable material in the clinical field, guaranteeing patient security and adequacy in different applications.

Features:

- Superelasticity: nitinol wire niti can undergo substantial deformation and return to its original shape upon heating.

- Shape Memory: It retains a predefined shape and can revert to it after deformation.

- Biocompatibility: Nitinol is well-tolerated by the human body, minimizing adverse reactions.

- Corrosion Resistance: It withstands harsh physiological environments, ensuring long-term performance.

Production Technology and Quality Control:

Our product is manufactured using advanced processing techniques, including vacuum induction melting and controlled rolling processes. Stringent quality control measures are implemented throughout production to guarantee consistency and compliance with industry standards. Each batch undergoes thorough inspection for dimensional accuracy, mechanical properties, and surface finish to uphold our commitment to excellence and patient safety.

FAQs:

- What is Nitinol wire? It is a shape memory alloy composed of nickel and titanium, renowned for its superelasticity and shape memory properties.

- What are the application areas of Nitinol wire? It finds use in orthodontics, vascular interventions, surgical instruments, and neurology, among others.

- Is Nitinol wire biocompatible? Yes, it is biocompatible and corrosion-resistant, making it suitable for medical implants and devices.

Final Details:

Baoji Hanz Metal Material Co., Ltd. is a leading manufacturer and supplier of nitinol wire medical. With a best in class office, broad stock, and different confirmations, we guarantee the brief conveyance of premium quality items.Our advanced production capabilities and stringent quality control measures guarantee that our super elastic nitinol medic wire meets the high standards required by the medical industry. By combining cutting-edge technology with a commitment to excellence, Baoji Hanz Metal Material Co., Ltd. consistently provides reliable and innovative solutions to medical professionals worldwide.For requests or to demand your modified Nitinol wire, kindly reach us at baojihanz-niti@hanztech.cn.

Send Inquiry

.webp)

.webp)