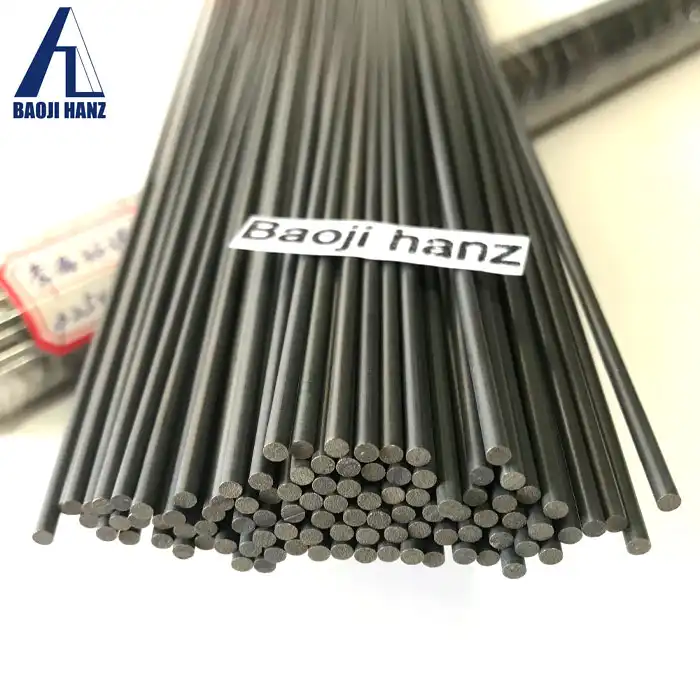

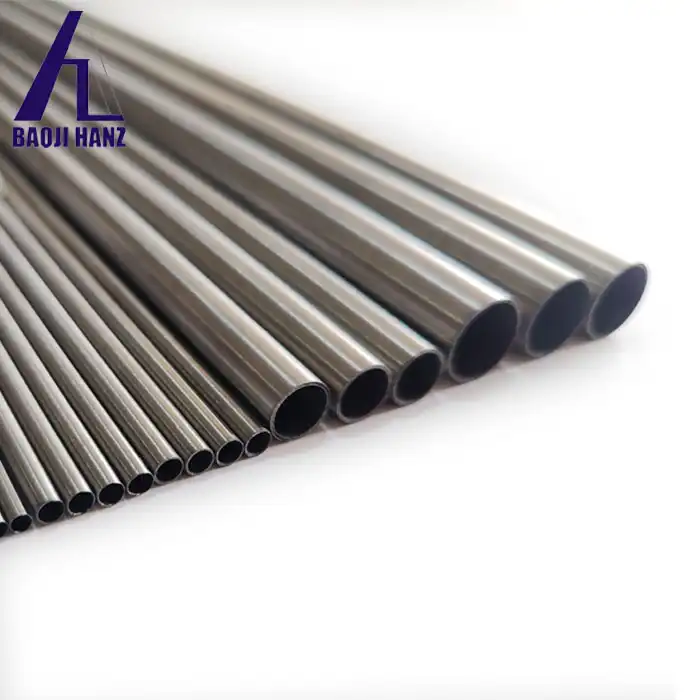

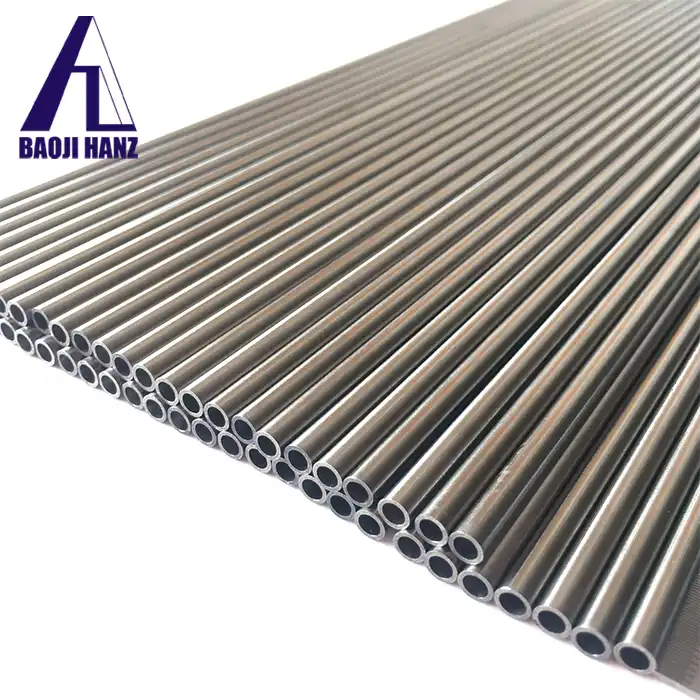

The Nickel Titanium Seamless Tube is a high-performance material widely used in various industries, including medical, aerospace, and electronics, thanks to its unique combination of strength, flexibility, and corrosion resistance. Made from nickel-titanium (NiTi) alloys, this seamless tube features excellent shape memory and superelastic properties, which make it ideal for applications requiring precise mechanical behavior. At Baoji Hanz Metal Material Co., Ltd., we manufacture top-quality Nitinium Seamless Tubes that meet international standards, ensuring excellent performance for every use.

Product Specifications

| Property | Specification |

|---|---|

| Material | Nitinol Alloy |

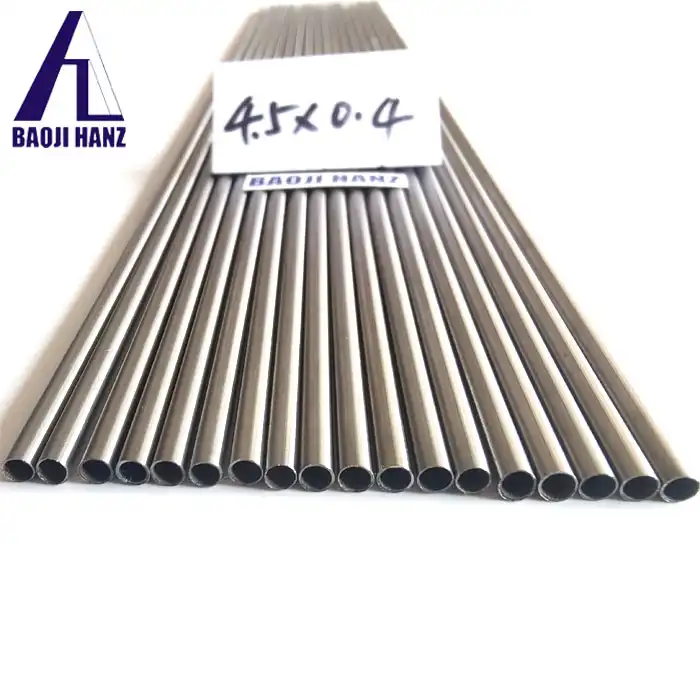

| Size Range | Outer diameter range: 0.20-15.0mm,Wall thickness range: 0.025-3.0mm |

| Wall Thickness | 0.1mm – 2mm |

| Standard | ASTM F2063-12,GB24627 |

| Certifications | ISO9001:2015, ISO13485:2016, EU CE Safety |

| MOQ | 5piece |

| Stock | Ready stock available for immediate shipment |

| OEM Services | Yes |

| Application | Interventional catheter, valve stent, peripheral stent, nerve interventional stent, etc |

Product Advantages

- Superior Mechanical Properties: The nickel titanium alloy offers exceptional superelasticity and shape memory, allowing the tube to return to its original form even after deformation.

- Corrosion Resistance: Resistant to a wide range of acids, alkalis, and other corrosive environments, making it ideal for demanding applications in harsh conditions.

- Biocompatibility: Safe for use in medical devices, particularly in implants and stents, thanks to its non-toxic nature.

- Customization: We offer tailored solutions for various diameters, lengths, and thicknesses to meet the unique needs of our clients.

Technical Features

- Shape Memory Effect: Exhibits a unique ability to "remember" its original shape after being deformed, activated by temperature changes.

- Superelasticity: The ability to undergo significant elastic deformation without permanent distortion, ideal for high-stress applications.

- Thermal Stability: The alloy's performance remains stable even at high temperatures, offering durability in high-heat environments.

- High Strength: Provides impressive tensile strength, capable of handling heavy loads without compromising its structural integrity.

Product Application

Nickel Titanium Seamless Tubes have a wide array of applications across multiple industries:

- Medical Field: Used in the production of stents, medical devices, and orthodontic tools, where precision and reliability are critical.

- Aerospace: Employed in aircraft components, actuators, and sensors that require shape memory characteristics for performance in extreme conditions.

- Electronics: Ideal for applications that require high flexibility and corrosion resistance, such as in electrical connectors and sensors.

- Automotive: Used in performance parts, especially in areas where materials are subjected to varying temperatures and pressures.

OEM Service

We provide comprehensive OEM services for customized Nitinol Seamless Tubes, tailored to meet your specific design, dimensional, and performance requirements. Whether you need custom sizes, shapes, or materials, our experienced engineering team can help bring your projects to life.

FAQ

- Q: Are Nitinol tubes magnetic?

-A: Generally speaking, the magnetic properties of nickel-titanium alloy tubes are very low. They are thought to be essentially non-magnetic under normal conditions.

- What is the effect of temperature on the performance of Nitinol tubes?

- A: The temperature has a significant impact. These tubes may be in martensitic phase with different mechanical properties at a certain phase transition temperature. At temperatures above this point, they transition into the austenitic phase, exhibiting shape memory effects and superelasticity. Extreme temperatures, whether too high or too low, can affect their performance and durability.

- Q: What is the typical wall thickness range of Nitinol tubes?

A: Depending on the application, the wall thickness of Nitinol tubes may vary greatly, but in general, it ranges from a few tenths of a millimeter to a few millimeters.

Q: Are there different surface treatments for Nitinol tubes?

Yes, common surface treatments include smooth finishes that require low friction and good biocompatibility, such as in medical devices, as well as texturing or coating treatments for specific industrial needs to improve adhesion or corrosion resistance.

- Q: Can Nitinol tubes be used in high-pressure situations?

A: Yes, but the design and thickness of the pipe need careful consideration. With proper engineering, they can be used in some high-pressure systems, such as certain hydraulic or pneumatic applications, where their unique properties are beneficial.

- Q: Are Nitinol tubes suitable for the food processing industry?

- A: In some cases, they can be used in the food processing industry. Their corrosion resistance and biocompatibility make them suitable for certain applications where they come in contact with food. However, it is important to ensure that the alloy meets the relevant food safety standards.

- Q:What are the challenges of Nitinol tube processing?

-A: Nitinol tubes are difficult to process due to their high hardness, low thermal conductivity and easy hardening. These characteristics can lead to rapid tool wear, poor surface finish, and increased machining difficulty.

- Q: Are Nitinol tubes easy to bend?

- A: They can be bent, but they require special techniques and equipment. Due to its superelasticity and shape memory effects, the bending process needs to be carefully controlled to avoid permanent deformation or damage to the properties of the alloy.

Q: Why are Nitinol tubes more expensive than other metal tubes?

-A: Nickel-titanium alloy tube due to the complex manufacturing process, high raw material costs, and has unique properties, so the price is higher. Production requires precise control of composition and heat treatment to achieve the desired shape memory and superelastic properties.

- Q: Is the price of Nitinol tube different in different specifications?

A: Yes, the price is affected by factors such as pipe diameter, wall thickness, length and surface finish. Larger diameters, thicker walls, and more complex finishes often lead to higher prices.

Contact Us

For more information or to place an order for Nickel Titanium Seamless Tubes, don’t hesitate to contact us!

- Email: baojihanz-niti@hanztech.cn

By focusing on quality, reliability, and customer satisfaction, Baoji Hanz Metal Material Co., Ltd. is committed to delivering world-class Nitinol seamless tubes that are carefully engineered to meet the specific needs of our clients. Our products are crafted using advanced technology and strict quality control measures to ensure exceptional performance, durability, and precision. Whether for medical, aerospace, or industrial applications, our Nitinol tubes offer unmatched flexibility and resilience. Let us be your trusted partner, and together we can help you achieve success in your next project with top-tier materials and expert support.

Send Inquiry

_1734967525655.webp)

_1734967525611.webp)

_1740042005804.webp)