Product Details:

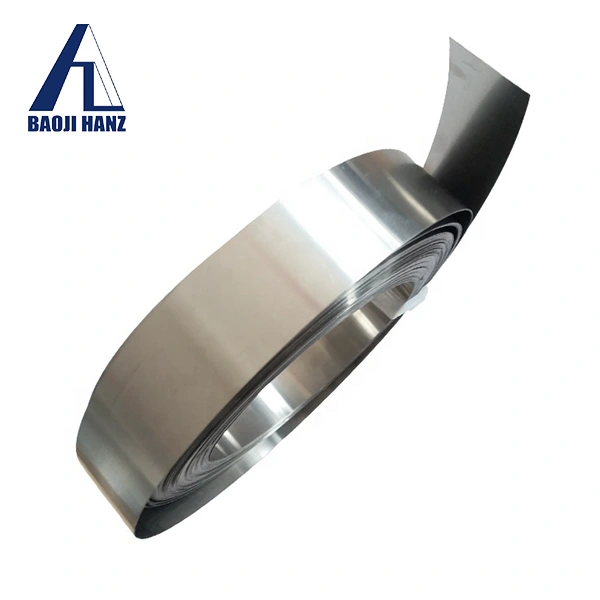

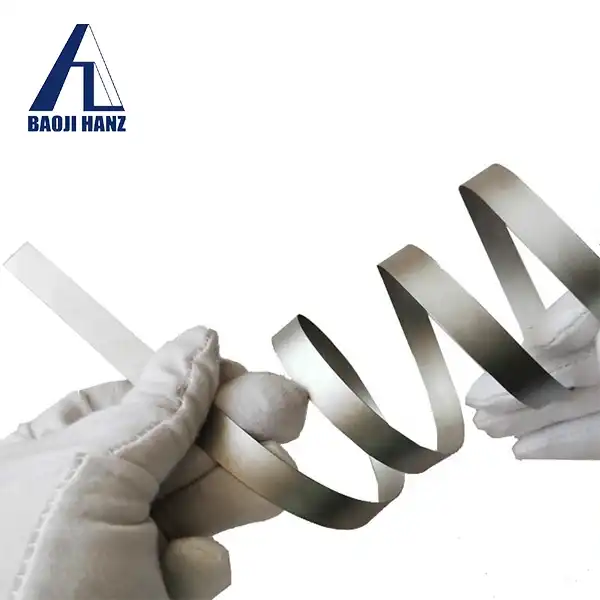

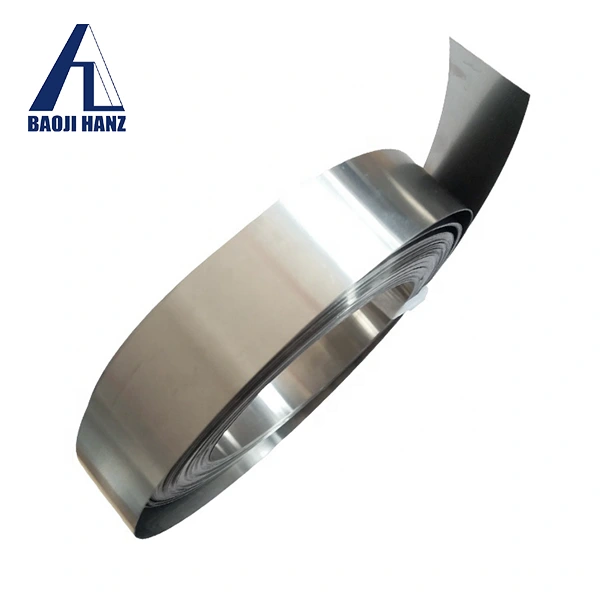

Our ASTM F2063 shape memory nitinol strip is a versatile and high-quality product designed for various applications in industries such as medical devices, aerospace, automotive, and more. Nitinol strip industrial is meticulously engineered to exhibit remarkable shape memory properties, allowing it to return to its predetermined shape when heated above its transformation temperature.

Chemical Composition:

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 55.8 - 57.0 |

| Titanium (Ti) | Balance |

| Iron (Fe) | <0.05 |

| Oxygen (O) | <0.02 |

| Carbon (C) | <0.05 |

| Nitrogen (N) | <0.02 |

Specifications:

| Thickness (mm) | Width (mm) | Length (m) | Transformation Temperature (°C) |

|---|---|---|---|

| 0.1 - 2.0 | 1 - 30 | Customized | 22 - 100 |

|

|

Application Areas:

Our nitinol strip finds extensive use in various applications, including:

- Medical Devices: Stents, guidewires, orthodontic archwires, and surgical instruments.

- Aerospace: Actuators, deployable structures, and vibration damping systems.

- Automotive: Engine components, sensors, and fuel injection systems.

- Consumer Electronics: Eyeglass frames, mobile phone antennas, and smartwatch components.

Features:

- Excellent shape memory effect and superelasticity.

- Biocompatibility, making it suitable for medical implants.

- High corrosion resistance and fatigue endurance.

- Customizable dimensions to suit specific application requirements.

- Repeatable and reliable performance over a wide temperature range.

Production Technology:

ASTM F2063 is a specification that outlines the requirements for shape memory nitinol strips. Nitinol, also known as nickel-titanium, is a unique alloy with shape memory properties, meaning it can "remember" its original shape and return to it when subjected to certain conditions.

Shape memory nitinol strips are widely used in various industries, including medical, aerospace, and automotive. The production technology for ASTM F2063 shape memory nitinol strip involves several key steps:

Alloy Composition: Nitinol is primarily composed of nickel and titanium, typically in equal proportions. The precise composition and purity of the alloy are critical to ensuring desired shape memory properties.

Melting and Casting: The first step is to melt and cast the nitinol alloy. This is usually done using vacuum induction melting or similar techniques to maintain the desired composition and minimize impurities.

Hot Working: The cast ingot is then hot-worked through processes like rolling or extrusion to achieve the desired strip dimensions. Hot working helps refine the microstructure of the material and enhances its mechanical properties.

Cold Working: After hot working, the strip is cold-rolled or cold-drawn to further reduce its thickness and improve its surface finish. Cold working increases the strength and hardness of the material while retaining its shape memory characteristics.

Heat Treatment: Shape memory nitinol strips undergo a specific heat treatment called "shape-setting" to establish the desired shape memory effect. This involves heating the strip above its transformation temperature and then cooling it rapidly to lock in the shape memory properties.

Finishing Operations: Various finishing operations such as cutting, grinding, and polishing are performed to achieve the final dimensions and surface quality required for the specific application.

Testing and Quality Control: Throughout the production process, the shape memory nitinol strips undergo rigorous testing to ensure they comply with the requirements specified in ASTM F2063. This includes mechanical testing, such as tensile strength and fatigue resistance, as well as evaluating shape memory characteristics.

It is important to note that the production technology may vary slightly depending on the specific manufacturer and application requirements. Compliance with ASTM F2063 ensures the quality and performance of shape memory nitinol strips for their intended use.

FAQs:

- What is the transformation temperature of your nitinol strip?

- The transformation temperature can be customized according to your specific requirements, typically ranging from 22°C to 100°C.

- Can you provide custom dimensions for the strip?

- Yes, we offer customization services to meet the unique needs of our customers.

- Is your nitinol strip biocompatible?

- Yes, our nitinol strip is biocompatible and suitable for use in medical implants.

Final Details:

Baoji Hanz Metal Material Co., Ltd. is a reputable manufacturer and supplier of ASTM F2063 shape memory nitinol strip. With our advanced production facilities, extensive inventory, and comprehensive certifications, we are committed to delivering superior-quality products and ensuring fast delivery to our customers worldwide. For inquiries or orders, please contact us at baojihanz-niti@hanztech.cn.

In conclusion, our nitinol strip for sale offers unmatched performance and reliability, making it the ideal choice for a wide range of applications. Trust Baoji Hanz Metal Material Co., Ltd. for all your nitinol strip needs.

Send Inquiry

.webp)

.webp)

.webp)