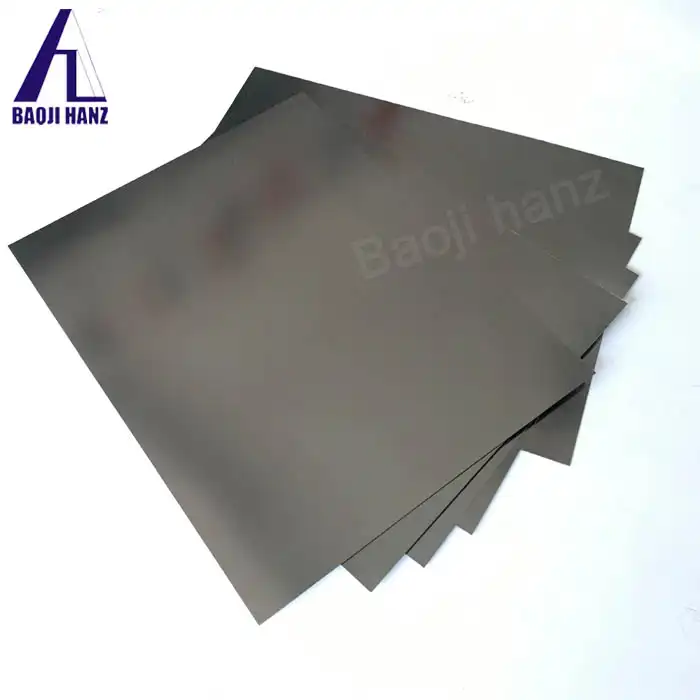

Superelastic Nitinol Sheets: Precision for Medical Applications

At Baoji Hanz Metal Material Co., Ltd., we specialize in providing high-quality superelastic nitinol sheets that meet the rigorous demands of medical device manufacturers and related industries. Known for their exceptional flexibility and durability, our nitinol sheets are designed to support a wide range of applications, from surgical tools to advanced medical devices.

Product Specifications

| Feature | Details |

|---|---|

| Material | Superelastic Nitinol (Nickel-Titanium Alloy) |

| Thickness | 0.05mm - 2.0mm |

| Width | 5mm - 500mm |

| Shape | Sheets, Plates |

| Surface Treatment | Polished, Oxidation-free |

| AF range | -20-100 Degree ℃ |

| MOQ | 1 piece |

| Density | 6.45g/cm3 |

| Tensile strength | 800pa |

| Sheet size | Thickness 0.1-10.0mm Width≤500mm Length≤1000mm |

Our products are available for immediate shipment, with factory-direct pricing and custom OEM services.

Product Advantages

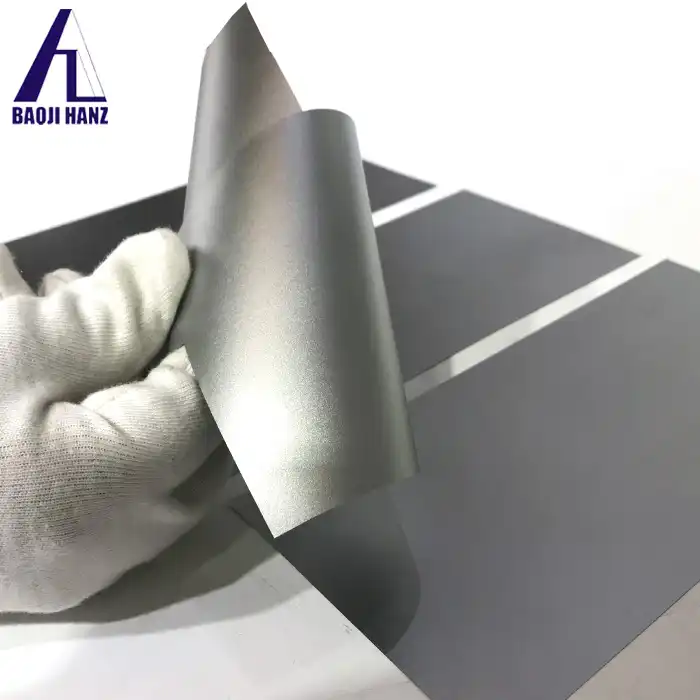

Our superelastic nitinol sheets are distinguished by a suite of exceptional characteristics that set them apart in the medical field. Foremost among these is their remarkable superelasticity, which allows the material to revert to its original shape after significant deformation. This property makes them particularly advantageous for applications in stents and surgical instruments, where precision and reliability are essential for patient outcomes.

In addition to their mechanical benefits, these nitinol sheets boast high biocompatibility, ensuring they are safe for use in various medical environments. This aspect is crucial, as it minimizes the risk of adverse reactions when in contact with human tissue, thus enhancing overall patient safety and comfort.

Moreover, the durability of our products cannot be overstated. They are highly resistant to both corrosion and wear, guaranteeing long-term reliability in medical devices. This resilience ensures that the materials maintain their integrity over extended periods, even in challenging conditions, ultimately supporting the longevity and efficacy of medical applications. These attributes collectively make our nitinol sheets an ideal choice for innovative healthcare solutions, combining functionality with safety and durability.

Technical Features

Nitinol, a remarkable alloy of nickel and titanium, offers an impressive array of technical features that revolutionize medical technology. One of its standout properties is shape memory, which allows nitinol to "remember" and revert to its original configuration upon heating. This unique characteristic is particularly transformative for applications such as stents and guidewires, where precise mechanical behavior is essential.

In addition to its shape memory capabilities, nitinol exhibits exceptional fatigue resistance, enabling it to withstand extensive repetitive motion without compromising performance. This makes it an ideal choice for long-term medical implants, where durability is crucial to ensure the longevity and reliability of devices embedded within the human body.

Furthermore, the excellent flexibility of nitinol sheets allows them to endure substantial deformation while still returning to their initial shape. This property is vital for the development of intricate and precise medical instruments, where maintaining structural integrity during use is paramount. Collectively, these technical features position nitinol as a leading material in advanced medical applications, offering innovative solutions that enhance patient care and operational effectiveness in healthcare settings.

Product Application

Our superelastic nitinol sheets are widely used in various medical fields, including:

- Stents: For vascular, esophageal, and urethral stents due to their biocompatibility and flexibility.

- Orthodontic Wires: For braces, offering patients comfort and reliability.

- Surgical Tools: Provides flexibility and precision for minimally invasive surgeries.

OEM Services

We provide tailored OEM services to meet the specific needs of our clients. Whether you need unique dimensions, specialized surface treatments, or customized packaging, Baoji Hanz Metal Material Co., Ltd. is here to help.

Company and equipment

Production process

ShippingFAQ

Performance aspect

- Q: How is the superelasticity of the superelastic nickel-titanium alloy plate?

A: After a large degree of deformation, the super-elastic nickel-titanium alloy plate can be completely restored to the original shape, and this recovery is spontaneous and repeatable, and the strain can be as high as about 8%.

Material composition

- Q: What are the main components of superelastic Nitinol plates?

- A: The main components are nickel and titanium, the general nickel content is between 54.5%-57%, the rest is titanium, also contains a small amount of impurities, such as carbon, hydrogen, oxygen, nitrogen, etc., the impurity content is usually controlled at a low level to ensure the performance of the alloy.

Phase transition temperature

- Q: What is the phase change temperature of the superelastic nickel-titanium alloy plate?

- A: The phase change temperature of different grades of superelastic nickel-titanium alloy plates is different, such as TiNi-02 phase change temperature of 45℃-90℃, TiNi-03 phase change temperature of less than 5℃ and so on.

Specification and size

- Q: What are the common specifications and sizes of super-elastic Nitinol plates?

- A: The common thickness is between 0.05mm and 5mm, the size specifications such as 0.1100100mm, 0.5200800mm, etc., can also be customized according to customer needs.

Application field

- Q: What are the main applications of superelastic nickel-titanium alloy plates?

- A: In the medical field can be used to manufacture medical devices such as stents, occluders, etc.; In the aerospace field, it can be used to make deformable wings, etc. In daily life, it can be used to manufacture spectacle frames, mobile phone antennas, etc.

Processing technology

- Q: What are the special requirements for the processing of super-elastic Nitinol plates?

- A: It is necessary to use high-precision processing equipment and special processing technology, such as CNC machining, to ensure its dimensional accuracy and surface quality. At the same time, due to its superelasticity, the deformation and rebound of the material need to be taken into account during the processing.

- QWhat is the minimum order quantity of superelastic Nitinol plates?

- A: 1pcs

- Q: How long is the lead time?

- A: If it is in stock, the delivery will be arranged within 2 to 3 days after the successful payment. It needs to be customized. It takes a long time.

Contact Us

For more details about our superelastic nitinol sheets , please reach out to us at:

- Email: baojihanz-niti@hanztech.cn

We look forward to collaborating with you to bring innovation and quality to your medical devices.

Send Inquiry

_1732953513708.webp)

_1732953513704.webp)

_1732953513682.webp)

_1732953513573.webp)

_1732953508425.webp)