Product Details:

Our Nitinol Memory Shape Alloy Spring are meticulously engineered to deliver exceptional performance in a wide range of applications. The shape memory effect is the ability of Nitinol to remember its original shape and return to it when heated above a certain temperature, known as the transformation temperature. This property allows these alloy springs to exhibit extraordinary flexibility and recoverability. They can be deformed, compressed, or bent into various shapes and then regain their original form upon heating. This characteristic makes them highly versatile and suitable for applications where repeated shape changes are required. Composed of nickel and titanium, these springs possess the unique ability to return to their original shape after deformation, making them ideal for various industries.

Crafted with precision, our nitinol springs exhibit superior elasticity, durability, and corrosion resistance, ensuring longevity and reliability in demanding environments. Available in various sizes and configurations and different nitinol spring price, these can be customized to meet specific requirements, providing unparalleled versatility for diverse applications.

Specifications:

| Place of Origin | Shaanxi, China |

| Brand Name | Baoji hanz |

| Service | OEM |

| The Max recovery stress | 600 MPa |

| AF | 55 centigrade celsius |

| Strength | 1300 Mpa |

| Tensile Strength | 900MPa |

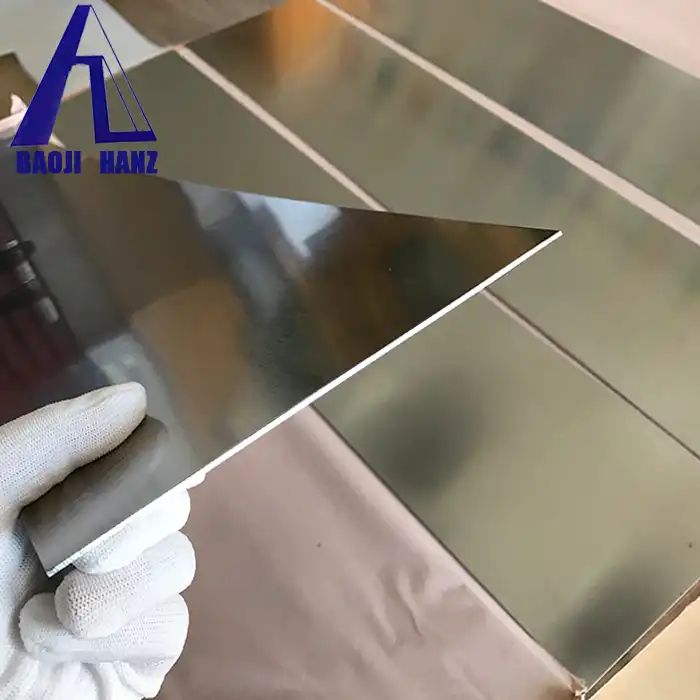

| surface | Black or polished |

| Materials | Nitinol alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 45% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Feature | Superelastic |

| Standard | ASTMF2063-05 |

| Application | Industry |

| MOQ | 500pcs |

Application Areas:

Our Nitinol Memory Shape Alloy Spring find extensive use in numerous industries, including:

- Medical Devices: Nitinol springs are utilized in stents, catheters, orthodontic wires, and surgical instruments due to their biocompatibility and shape memory properties.

- Aerospace: These springs are employed in actuators, valves, and mechanisms where lightweight, reliable components are essential.

- Automotive: Nitinol springs are integrated into automotive systems for applications such as fuel injection systems and exhaust components, enhancing efficiency and performance.

- Robotics: These springs play a crucial role in robotic joints, grippers, and mechanisms, providing precise motion control and flexibility.

- Consumer Electronics: Nitinol springs are utilized in smart devices, wearables, and small appliances for their compact size, energy efficiency, and durability.

Features:

- Shape Memory Effect: Nitinol memory shape alloy spring ability to return to a predetermined shape upon heating.

- Superelasticity: High resilience and elasticity, allowing for repeated deformation without permanent damage.

- Corrosion Resistance: Excellent resistance to corrosion, ensuring longevity in harsh environments.

- Customization: Available in various sizes, shapes, and configurations to suit specific application requirements.

- Biocompatibility: Suitable for medical applications, compatible with the human body without adverse reactions.

Production Technology:

Our nitinol shape memory alloy spring are manufactured using advanced production techniques, including:

- Vacuum Induction Melting (VIM): Ensures precise control over the chemical composition and purity of the alloy.

- Hot/Cold Working: Forming the alloy into desired shapes and sizes through processes such as rolling, forging, or drawing.

- Heat Treatment: Achieving the desired mechanical properties, including shape memory effect and superelasticity, through controlled heating and cooling cycles.

Quality Control:

At Baoji Hanz Metal Material Co., Ltd., we prioritize quality assurance throughout the production process. Our experienced technicians conduct rigorous testing and inspection at every stage, ensuring that our nitinol springs meet the highest standards of performance and reliability.

Nitinol Production Process&Shipping

Company and equipment

Other related product catalogues

Nickel titanium memory alloy in addition to the production of nickel-titanium strips, can also produce other similar products, such as nickel-titanium plate, nickel titanium flat wire, nickel titanium foil, nickel titanium wire, nickel titanium tube, nickel titanium spring, nickel titanium paper clips, nickel titanium wire rope.

|

|

|

|

|

|

|

|

FAQs:

- What is the maximum operating temperature of nitinol shape memory alloy spring?

- The maximum operating temperature typically ranges from 70°C to 100°C, depending on the specific alloy composition and application.

- Can Nitinol springs be recycled?

- Yes, Nitinol springs can be recycled through processes such as melting and reprocessing to reclaim the nickel and titanium content.

- How can I determine the appropriate size and configuration for my application?

- Our team of experts is available to provide personalized assistance and guidance to help you select the optimal nitinol spring for your specific requirements.

Final Details:

Baoji Hanz Metal Material Co., Ltd. is a trusted manufacturer and supplier of products, offering a comprehensive range of products with large inventory, complete certificates, and fast delivery. For inquiries or to request nitinol spring price, please contact us at baojihanz-niti@hanztech.cn. Choose Baoji Hanz for superior quality and reliability in nitinol springs.

Send Inquiry

.webp)

.webp)

.webp)

.webp)

.webp)