Can nitinol tubes be customized for specific applications?

2024-09-27 19:54:24

Nitinol tubes, known for their unique shape memory and superelastic properties, have revolutionized various industries with their remarkable capabilities. These tubes, composed of nickel and titanium alloys, possess the ability to return to their original shape after deformation when exposed to specific temperatures or stresses. This blog explores the fascinating world of shape memory nitinol tubes and delves into their customization potential for diverse applications. We'll examine the manufacturing processes, design considerations, and the wide array of industries benefiting from tailored nitinol tube solutions, we uncover the remarkable versatility and adaptability of these extraordinary materials.

Understanding Shape Memory Nitinol Tubes

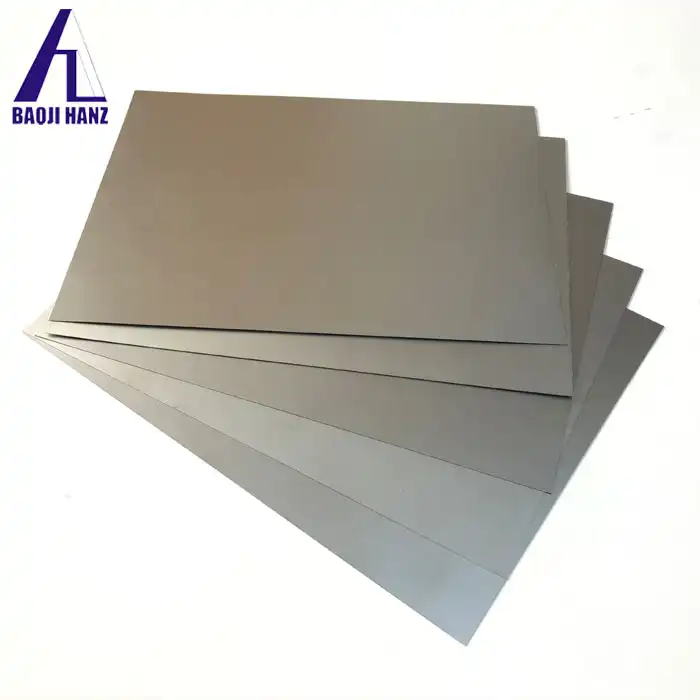

Composition and Properties of Nitinol

Nitinol, an acronym for Nickel Titanium Naval Ordnance Laboratory, is a remarkable alloy composed of nearly equal parts nickel and titanium. This unique composition grants nitinol its extraordinary properties, including shape memory and superelasticity. The shape memory effect allows nitinol tubes to return to a predetermined shape when heated above their transformation temperature, while superelasticity enables them to undergo large deformations without permanent damage. The crystal structure of nitinol plays a crucial role in its behavior. At low temperatures, nitinol exists in a martensite phase, which is relatively soft and easily deformable. When heated above its transformation temperature, it transitions to the austenite phase, becoming stronger and more rigid. This phase transformation is the key to nitinol's shape memory capabilities.

Shape Memory Effect in Nitinol Tubes

The shape memory effect in nitinol tubes is a fascinating phenomenon that sets them apart from conventional materials. When a nitinol tube is deformed at a low temperature, it retains its new shape. However, upon heating above its transformation temperature, the tube "remembers" its original form and returns to it. This process can be repeated numerous times without significant degradation of the material's properties. The shape memory effect occurs due to the reversible, diffusionless transformation between the martensite and austenite phases. This unique characteristic allows nitinol tubes to be programmed with specific shapes, making them ideal for applications requiring controlled, repeatable movements or shape changes in response to temperature variations.

Superelasticity in Nitinol Tubes

Superelasticity, another remarkable property of nitinol tubes, allows them to undergo large deformations and immediately return to their original shape upon removal of the applied stress. This behavior is particularly evident at temperatures above the material's austenite finish temperature. The superelastic effect is a result of stress-induced martensite formation. When stress is applied to a nitinol tube in its austenitic state, it transforms into martensite, allowing for significant deformation. Upon removal of the stress, the martensite reverts to austenite, and the tube springs back to its original shape. This property makes nitinol tubes exceptionally resilient and capable of withstanding repeated cycles of deformation without fatigue or permanent damage.

Customization Techniques for Nitinol Tubes

Heat Treatment and Shape Setting

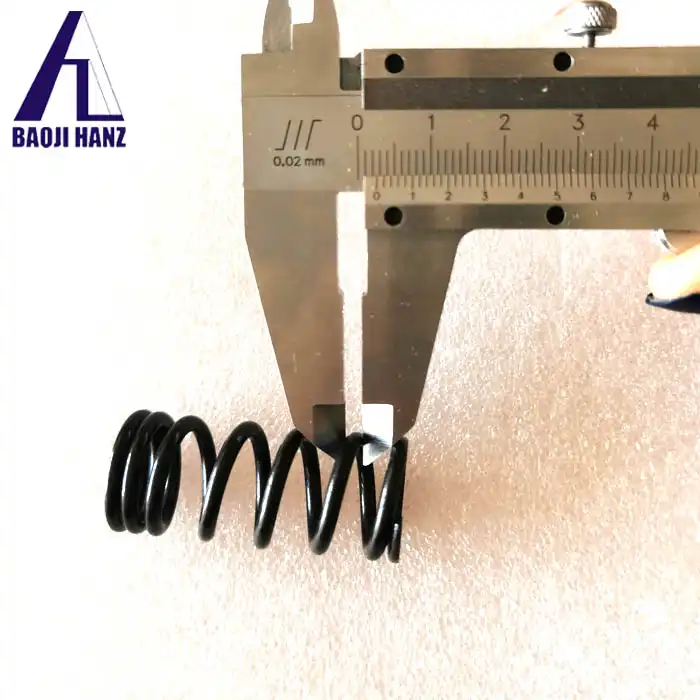

Heat treatment is a crucial step in customizing shape memory nitinol tubes for specific applications. The process involves heating the tube to a specific temperature and holding it there for a predetermined time before cooling. This treatment alters the material's microstructure, affecting its transformation temperatures and mechanical properties. Shape setting is a specialized heat treatment technique used to program desired shapes into nitinol tubes. The tube is first constrained in the desired configuration using a fixture or mold. It is then heated to a high temperature, typically between 450°C and 550°C, for a specific duration. After cooling, the tube retains the new shape and will return to it when heated above its transformation temperature.

Surface Modifications and Coatings

Surface modifications can significantly enhance the performance and biocompatibility of nitinol tubes. Electropolishing is a common technique used to smoothen the surface, remove impurities, and create a uniform oxide layer. This process improves corrosion resistance and reduces the risk of nickel leaching in biomedical applications. Various coatings can be applied to nitinol tubes to impart specific properties. For instance, titanium nitride coatings can enhance wear resistance and reduce friction, while hydroxyapatite coatings promote osseointegration in orthopedic implants. Polymer coatings may be used to improve lubricity or drug delivery capabilities in medical devices.

Precision Machining and Laser Cutting

Precision machining techniques allow for the creation of complex geometries and features in nitinol tubes. Computer Numerical Control (CNC) machining can be used to create precise cuts, grooves, or holes in the tubes. However, care must be taken to avoid work hardening of the material during machining, which can alter its properties. Laser cutting has emerged as a powerful tool for customizing nitinol tubes. This non-contact method allows for the creation of intricate patterns and designs without affecting the material's properties. Laser cutting is particularly useful for manufacturing stents, filters, and other medical devices that require complex geometries with tight tolerances.

Applications of Customized Nitinol Tubes

Medical Devices and Implants

The medical industry has embraced customized nitinol tubes for a wide range of applications. In interventional cardiology, nitinol stents are used to treat coronary artery disease. These stents can be compressed into a small diameter for minimally invasive delivery and then expand to support the artery wall. The superelastic properties of nitinol allow the stents to flex with the natural movement of the blood vessels. Orthopedic implants also benefit from customized nitinol tubes. Shape memory bone staples, for example, can be cooled and deformed for easy insertion into bone. Once in place, body heat activates the shape memory effect, causing the staple to close and provide compression across the fracture site. This approach simplifies surgical procedures and promotes faster healing.

Aerospace and Automotive Industries

In aerospace applications, customized nitinol tubes find use in adaptive structures and actuators. Shape memory nitinol tubes can be incorporated into aircraft wings to change their shape in flight, optimizing aerodynamic performance under different conditions. This technology, known as morphing wings, has the potential to significantly improve fuel efficiency and flight characteristics. The automotive industry utilizes nitinol tubes in various components, such as thermal actuators for climate control systems. These actuators can respond to temperature changes without the need for complex electronic controls, simplifying vehicle design and improving reliability. Nitinol tubes are also being explored for use in impact-absorbing structures, leveraging their superelastic properties to enhance vehicle safety.

Consumer Electronics and Robotics

Consumer electronics benefit from the unique properties of customized nitinol tubes. In smartphones and tablets, nitinol wire-form antennas can be compressed into small spaces and deploy when needed, improving signal reception without compromising device aesthetics. Nitinol tubes are also used in camera autofocus mechanisms, providing silent and precise lens movement. In robotics, shape memory nitinol tubes enable the creation of compact, lightweight actuators. These actuators can produce significant force and displacement with minimal power input, making them ideal for applications in soft robotics and biomimetic systems. Customized nitinol tubes allow engineers to design robots with flexible, adaptive structures that can navigate complex environments and interact safely with humans.

Conclusion

Customized nitinol tubes offer unparalleled versatility and performance across various industries. From life-saving medical devices to innovative aerospace technologies, the ability to tailor these remarkable materials to specific applications continues to drive innovation and solve complex engineering challenges. As research and manufacturing techniques advance, we can expect even more exciting developments in the field of shape memory nitinol tubes. If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1. Duerig, T. W., & Pelton, A. R. (2019). Nitinol: The Material and Its Applications. Advanced Materials & Processes, 177(5), 22-26.

2. Morgan, N. B. (2004). Medical shape memory alloy applications—the market and its products. Materials Science and Engineering: A, 378(1-2), 16-23.

3. Sun, L., Huang, W. M., Ding, Z., Zhao, Y., Wang, C. C., Purnawali, H., & Tang, C. (2012). Stimulus-responsive shape memory materials: a review. Materials & Design, 33, 577-640.

4. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design (1980-2015), 56, 1078-1113.

5. Lagoudas, D. C. (Ed.). (2008). Shape memory alloys: modeling and engineering applications. Springer Science & Business Media.

6. Nematollahi, M., Baghbaderani, K. S., Amerinatanzi, A., Zamanian, H., & Elahinia, M. (2019). Application of NiTi in assistive and rehabilitation devices: a review. Bioengineering, 6(2), 37.

.webp)