What is a nitinol ingot?

2024-08-05 11:36:29

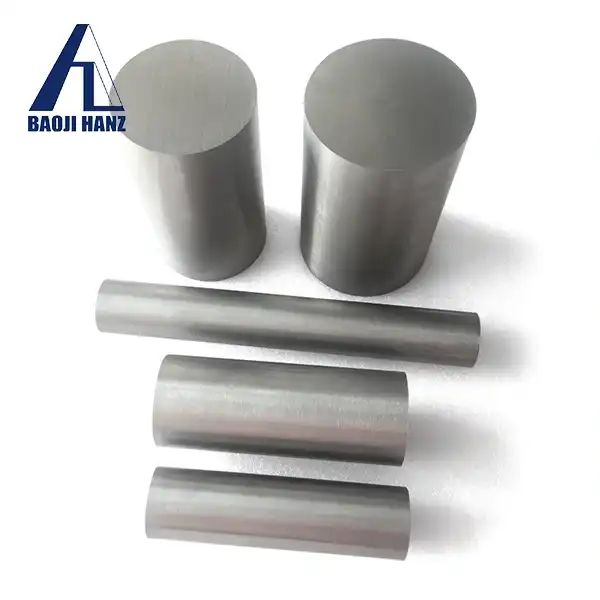

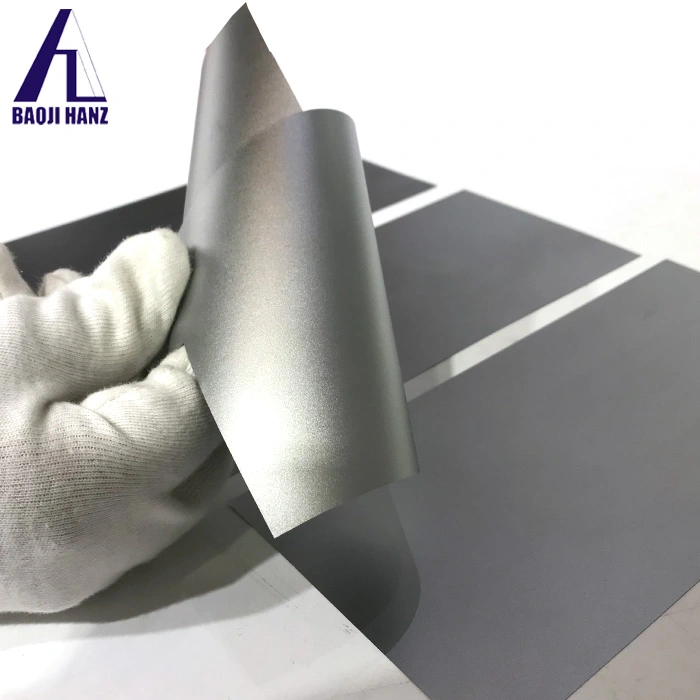

A Nitinol ingot is a raw material block made of a nickel-titanium alloy, known for its unique properties such as shape memory and superelasticity. It is produced through processes like vacuum arc melting, where precise proportions of nickel and titanium are melted under controlled conditions to form a solid ingot. Nitinol ingots serve as the basis for manufacturing components used in diverse industries, including medical devices, aerospace, and consumer electronics. Their ability to return to a predetermined shape and withstand repeated deformation makes them valuable for applications requiring reliable and resilient materials with specific mechanical characteristics.

How are Nitinol Memory Ingots Produced?

Nitinol memory ingots are produced through a specialized manufacturing process called vacuum induction melting (VIM). In this process, high-purity nickel and titanium are melted together under a vacuum environment to prevent oxidation and ensure precise control over the alloy composition. The molten metal is then cast into ingots and cooled in a controlled manner to form solid blocks. These ingots undergo further processing steps such as hot and cold working, heat treatment, and machining to develop their shape memory and superelastic properties. Quality control measures ensure consistency in material performance for applications in medical devices, aerospace, and other high-tech industries.

What are the Applications of Shape Memory Nitinol Ingots?

Shape memory Nitinol ingots find diverse applications across industries:

Medical Devices: Used in stents, guidewires, orthodontic braces, and surgical instruments due to their ability to return to a programmed shape.

Aerospace: Employed in actuators, hinges, and structural components that require lightweight and reliable performance.

Automotive: Used in sensors, valves, and engine components for adaptive and responsive systems.

Consumer Electronics: Applications include micro actuators, connectors, and switches for compact and efficient devices.

Robotics: Utilized in robotic actuators and mechanisms for precise movement and flexibility.

Industrial Applications: Used in valves, clamps, and tooling for adaptive and automated manufacturing processes.

Sporting Goods: In applications such as eyeglass frames and archery bows for flexibility and durability.

Shape memory Nitinol ingots enable innovative designs and solutions in various fields by providing unique mechanical properties and reliability under diverse conditions.

Why is Nitinol Used for Medical Devices?

Nitinol is used for medical devices due to its unique properties like biocompatibility, corrosion resistance, and superelasticity. These characteristics allow Nitinol to withstand deformation and return to its original shape, making it ideal for applications such as stents, guidewires, and orthodontic braces. Its ability to respond to temperature changes within the body ensures precise and reliable performance in minimally invasive surgeries. Nitinol's durability and compatibility with human tissues reduce the risk of adverse reactions, making it a preferred material in medical technology for enhancing patient outcomes and ensuring long-term implant success.

Conclusion

In conclusion, nitinol ingots represent a crucial stage in the production of shape memory alloys with unique mechanical properties. Understanding their production methods and applications illuminates their significance across various high-tech industries, particularly in healthcare and aerospace. As technology advances, the role of nitinol ingots is likely to expand further, driven by ongoing research and development.

References

- "Shape Memory Alloys" - Materials Science and Engineering: An Introduction, 9th Edition, Wiley.

- "Medical Applications of Nitinol" - Journal of Materials Science: Materials in Medicine, Springer.

- "Advances in Nitinol Manufacturing Techniques" - ASM International Handbook.