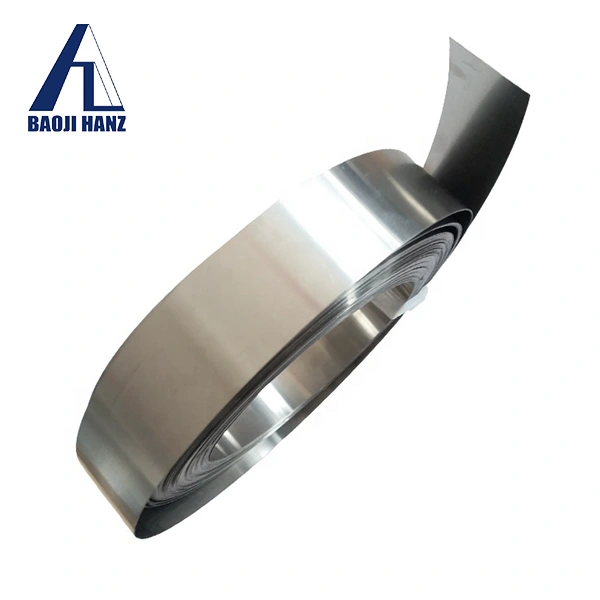

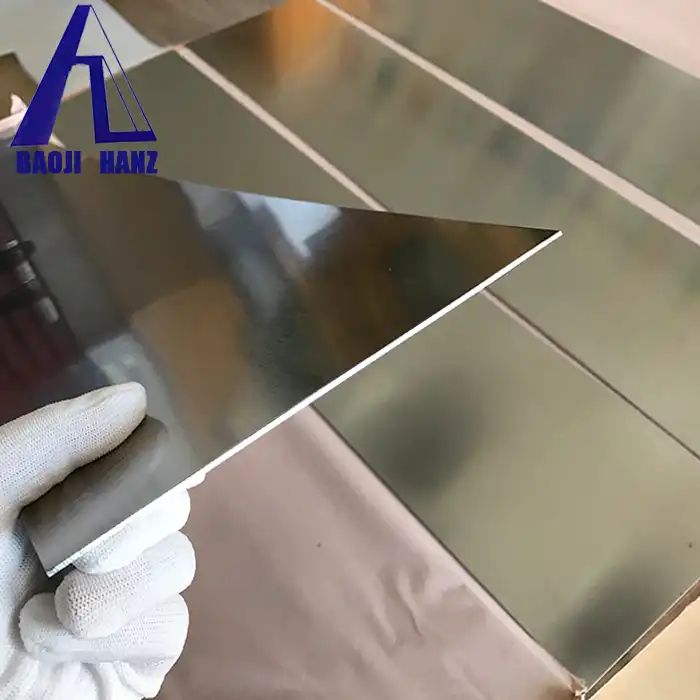

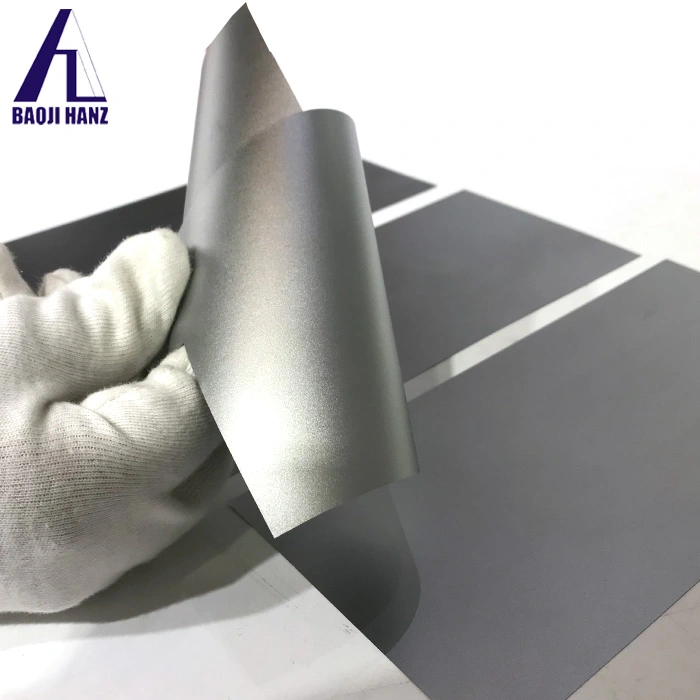

Product Details:

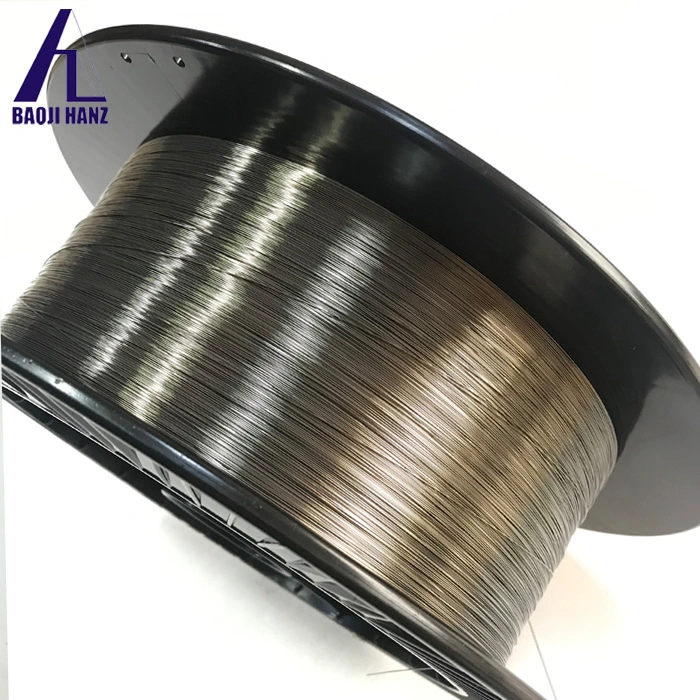

Our medical grade nitinol wire memory products are meticulously engineered to provide outstanding performance across a wide spectrum of medical applications. Crafted from top-tier nitinol alloy, these wires showcase exceptional shape memory and superelasticity, positioning them as optimal choices for a multitude of critical medical procedures.

The meticulous engineering of our nitinol buy wire products ensures that they meet the stringent demands of the medical field. Through the utilization of high-quality nitinol alloy, these wires offer superior biocompatibility and corrosion resistance, essential attributes for medical devices. Their remarkable shape memory properties empower them to maintain a predetermined shape even after undergoing significant deformation, enabling precise placement and deployment in minimally invasive surgeries and interventional procedures.

Furthermore, the inherent superelasticity of our nitinol wires equips them to withstand substantial bending and twisting forces without permanent deformation, contributing to their reliability in demanding medical applications. This unique combination of shape memory and superelasticity makes our nitinol wire memory products indispensable in various medical interventions, including stent delivery, embolization, and endoscopic procedures.

Our nitinol buy wire products stand as prime examples of cutting-edge engineering and material science, offering healthcare professionals the confidence and assurance they seek when undertaking intricate and delicate medical procedures.

Specifications:

| Place of Origin | Shaanxi, China |

| Brand Name | Baoji hanz |

| Color | Black, brown, brown, blue, bright |

| Materials | Nitinol alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 45% |

| Strength | 980 Mpa |

| Processing Service | Bending, Welding, Decoiling |

| Wire Gauge | 0.02mm min |

| Tensile strength | 980 Mpa |

| Feature | Shape memory |

| Supply Status | Full annealed |

| Modulus of elasticity | Austenite 83 Gpa |

| The Max recovery stress | 185 MPa |

| Standard | ASTM F2063, Q/XB1516 |

| Certificate | ISO9001:2015 |

| Application | Guide wires Shape set parts ,Orthodontic Files .Arch wire . fishing wire .bra frames wire .glasses wire .spring wire |

| Chemical element | Af range | Available production Line | Usage | Sample |

| Nickel 55% Titanium 45% | 0℃to 100℃ | Rod&wire,Plate&sheet,Strip&foil | Medical&Industry | On stock (various specification) |

| Nickel 55% +V +Ti | ||||

| Nickel 55% +Fe +Ti | Subzero 30℃ to -5 ℃ | Rod&wire,Plate&sheet | Industry | On stock |

| Nickel 55%+Cr +Ti | (limitedspecification) | |||

| Nickel 55% +Hf +Ti | Above 100C | Ingot | Ingot | Updating |

| The production certification | ||||||

| Specification (mm) | Shape Memory Nitinol wire | Typical Medical industry Application | ||||

| UTS (Mpa) | Elongation % | UpperPlateau Stress Mpa | Permanent Set after 6% strain % | Active AF | ||

| 0.1-0.3mm | ≥1100 | ≥15 | ≥480 | <0.5 | Subzero20~100 | Guide wires Shape set parts, orthodontic files, arch wire, fishing wire, bra frames wire, glasses wire,spring wire |

| 0.3~0.6mm | ≥920 | ≥15 | ≥440 | <0.5 | ||

| 0.6~3.0mm | ≥850 | ≥15 | ≥440 | <0.5 | ||

Application Areas:

Our medical grade nitinol wire memory finds extensive use in various medical fields, including:

- Cardiology: Used in stents for coronary artery disease treatment.

- Orthopedics: Employed in bone fixation devices and orthodontic appliances.

- Neurology: Utilized in neurovascular interventions and aneurysm treatment.

- Endovascular Surgery: Essential for peripheral vascular disease management.

- General Surgery: Facilitates minimally invasive surgical procedures.

Features:

- Shape Memory: Returns to its original shape upon heating.

- Superelasticity: Withstands extreme deformations without permanent damage.

- Biocompatibility: Compatible with the human body, minimizing adverse reactions.

- High Fatigue Resistance: Maintains performance under repetitive loading.

- Precise Dimensional Control: Ensures accuracy in medical device manufacturing.

Production Technology:

The production of our nitinol wire price per pound involves the utilization of highly advanced manufacturing processes that are designed to guarantee uniform composition and exceptional mechanical properties. Through meticulous control of the alloy composition and rigorous application of thermomechanical processing, we consistently achieve a level of product quality that meets and surpasses international standards.

The foundation of our manufacturing process lies in the precise control of the nitinol alloy composition. By adhering to stringent specifications and employing state-of-the-art analytical techniques, we ensure that the nitinol wires exhibit a uniform and reliable composition throughout, thereby establishing a solid foundation for their exceptional performance in medical applications. This attention to detail in alloy composition is pivotal in ensuring that our nitinol wires possess the necessary attributes such as biocompatibility, corrosion resistance, and durability, which are imperative for their usage in critical medical procedures.

Furthermore, our manufacturing process incorporates highly specialized thermomechanical processing techniques that are tailored to optimize the mechanical properties of the nitinol wires. Through carefully calibrated heat treatments and mechanical deformation, we impart the wires with remarkable shape memory and superelasticity, characteristics that are indispensable for their successful deployment in various medical interventions. Additionally, the precision control exercised during the thermomechanical processing ensures that each wire maintains consistent and predictable performance, meeting the exacting demands of medical professionals.

The adherence to such exacting manufacturing standards enables us to consistently produce nitinol wire memory products that not only meet but exceed international quality benchmarks. Our commitment to precision and excellence in manufacturing translates into medical grade nitinol wires that provide healthcare practitioners with the confidence and reliability they require when navigating complex and delicate medical procedures.

Quality Control:

At Baoji Hanz Metal Material Co., Ltd., quality is paramount. Our nitinol wire price per pound undergoes rigorous inspection at every stage of production to guarantee compliance with stringent specifications. From raw material procurement to final product testing, we adhere to strict quality control protocols to deliver products of unparalleled reliability.

FAQs:

-

What is nitinol? Nitinol is a nickel-titanium alloy known for its unique shape memory and superelastic properties.

-

Is nitinol biocompatible? Yes, nitinol is widely regarded as biocompatible and is extensively used in medical implants and devices.

-

Can nitinol be sterilized? Yes, nitinol can be sterilized using standard medical sterilization techniques such as autoclaving or ethylene oxide sterilization.

Final Details:

Baoji Hanz Metal Material Co., Ltd. is a leading manufacturer and supplier of medical grade nitinol wire memory with a dedicated factory, extensive inventory, complete certifications, and prompt delivery. For inquiries or orders, please contact us at baojihanz-niti@hanztech.cn.

By choosing our product, you are assured of premium quality products backed by expertise and reliability. Experience the difference with Baoji Hanz Metal Material Co., Ltd.

Send Inquiry

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)