Product Details:

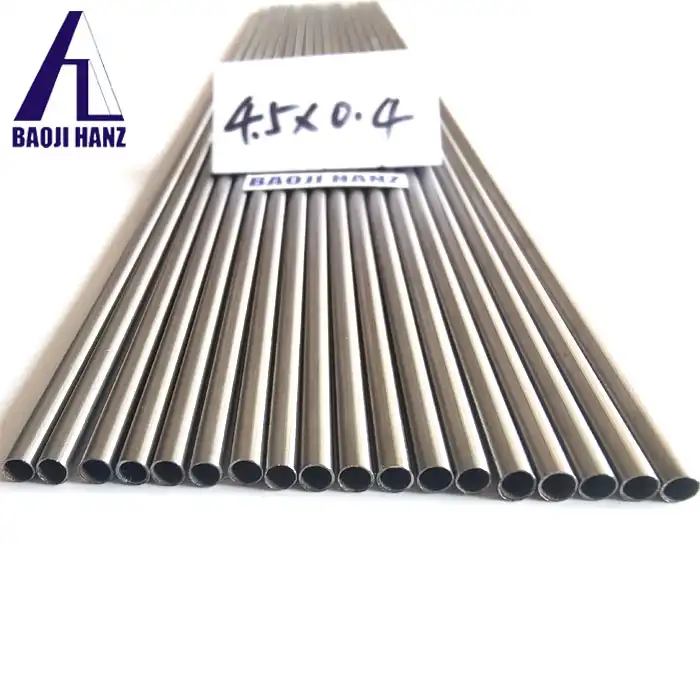

Our Alloy Nitinol Tube is a remarkable engineering material known for its unique properties and wide range of applications. Crafted meticulously at Baoji Hanz Metal Material Co., Ltd., each tube exemplifies precision engineering and superior quality.

Nitinol, a nickel-titanium alloy, exhibits shape memory and superelasticity, making it ideal for various demanding applications. Our shape memory alloy nitinol tubes boast exceptional flexibility, durability, and biocompatibility, making them indispensable in industries such as medical devices, aerospace, automotive, and robotics.

Specifications:

Refer to the table below for detailed specifications of our products:

| Place of Origin | Shaanxi, China |

| Brand Name | Baoji hanz |

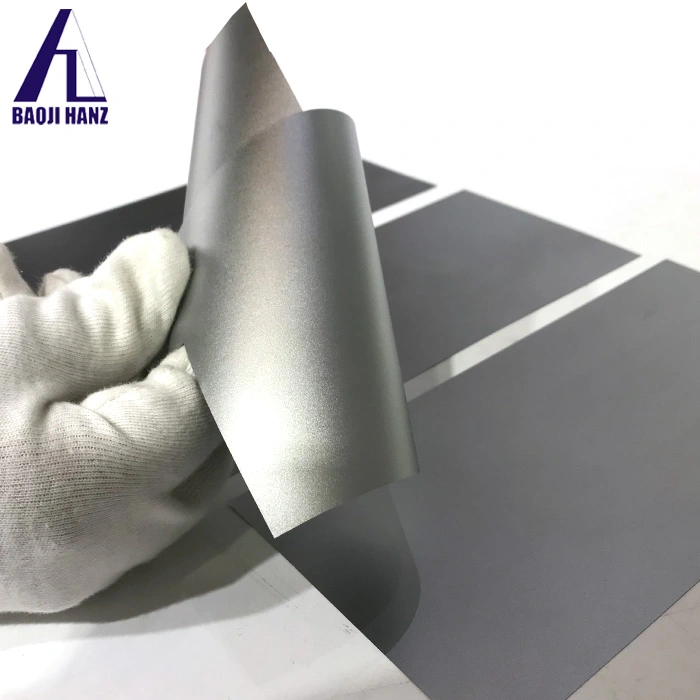

| Color | Bright |

| Materials | Nitinol alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 45% |

| Processing Service | Bending, Decoiling, Cutting, Punching |

| Feature | Shape memory |

| Technique | Seamless |

| Shape | Round Shape |

| Supply Status | Annealling |

| The Max recovery stress | 1200Mpa |

| Standard | ASTM F2063-12/18 |

| Certificate | ISO9001:2015 |

| Application | Catheter / stents |

| Chemical element | Af range | Available production Line | Usage | Sample |

| Nickel 55% Titanium 45% | 0℃to 100℃ | Rod&wire,Plate&sheet,Strip&foil | Medical&Industry | On stock (various specification) |

| Nickel 55% +V +Ti | ||||

| Nickel 55% +Fe +Ti | Subzero 30℃ to -5 ℃ | Rod&wire,Plate&sheet | Industry | On stock |

| Nickel 55%+Cr +Ti | (limitedspecification) | |||

| Nickel 55% +Hf +Ti | Above 100C | Ingot | Ingot | updating |

|

|

Application Areas:

Alloy nitinol tubes have garnered significant prominence across a wide spectrum of industries, owing to their exceptional properties. Here are some key application areas:

Medical Devices: These tubes play a vital role in the production of medical devices like stents, catheters, guidewires, and orthodontic archwires. Their biocompatibility and shape memory capabilities make them indispensable in various procedures.

Aerospace: The products find extensive use in aerospace applications, particularly in actuators, valves, and components that require a combination of lightweight construction and high strength. Their ability to withstand extreme conditions makes them ideal for critical aerospace systems.

Automotive: The automotive industry benefits from the integration of nitinol alloy pipes in sensors, actuators, and fuel injection systems. Their excellent corrosion resistance and thermal stability contribute to improved performance and efficiency.

Robotics: The products are seamlessly incorporated into robotic components, enhancing flexibility and enabling precise control. Their shape memory effect allows for intricate movements and adaptability in robotic systems.

These diverse application areas highlight the versatility and reliability of the tubes, making them a preferred choice across industries that demand advanced engineering solutions.

Features:

Nitinol alloy tubes are a prime example of next-generation materials that offer a wealth of exceptional features, ensuring their widespread use across multiple industries. The shape memory effect is one of Nitinol's standout features, enabling these tubes to return to their original shape upon heating, with remarkable precision and reliability. Superelasticity is another defining attribute, as Nitinol tubes can withstand significant stress while retaining their original form, making them ideal for challenging mechanical conditions. In medical applications, biocompatibility is crucial, and Nitinol tubes fit the bill, as they are safe for use in implants and have demonstrated compatibility with human tissue without adverse reactions.

Furthermore, Nitinol tubes are renowned for their corrosion resistance, rendering them suitable for deployment in harsh and corrosive environments where conventional materials falter. Last but not least, their high fatigue resistance ensures enduring performance even under the most rigorous conditions of repeated loading, guaranteeing longevity and reliability in critical applications.

In essence, Nitinol alloy tubes embody a fusion of cutting-edge material science and engineering prowess, offering a suite of features that cater to the demands of modern innovation across a spectrum of industries.

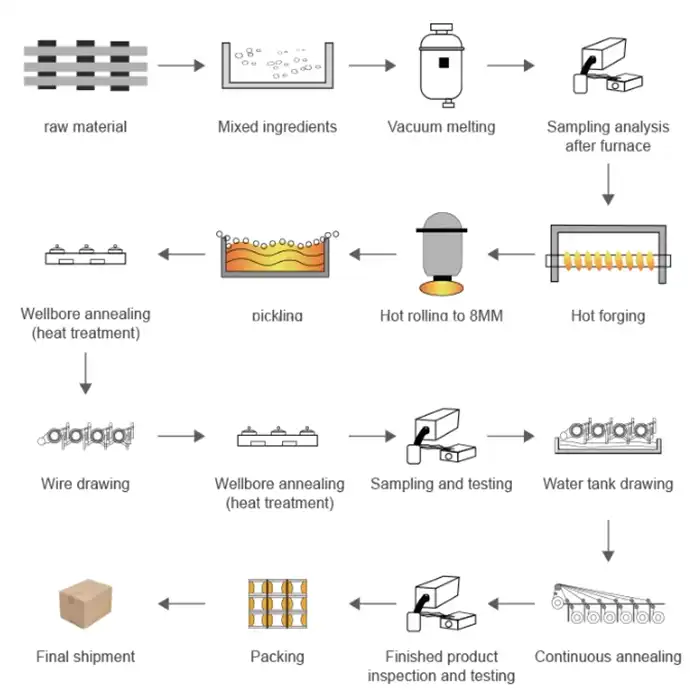

Production Technology:

The manufacturing of our shape memory ally nitinol tube leverages cutting-edge techniques like vacuum melting, hot extrusion, and cold drawing. These methods are instrumental in guaranteeing exacting dimensional precision, impeccable surface refinement, and uniform mechanical characteristics. Through the seamless integration of these advanced processes, we uphold unparalleled standards of quality and reliability in our product offerings.

Quality Control:

We adhere to stringent quality standards throughout the production process. Each nitinol alloy pipe undergoes rigorous testing for dimensional accuracy, mechanical properties, and surface integrity before dispatch.

Manufacturing Technique:

Shipping:

FAQs:

-

What is Nitinol? Nitinol is a nickel-titanium alloy known for its unique shape memory and superelasticity.

-

Is Nitinol biocompatible? Yes, Nitinol is widely used in medical implants due to its excellent biocompatibility.

-

Can Nitinol be welded? Yes, Nitinol can be welded using specialized techniques such as laser welding and electron beam welding.

Final Details:

Baoji Hanz Metal Material Co., Ltd. is a leading manufacturer and supplier of alloy nitinol tubes. With our state-of-the-art facility, extensive inventory, and complete certifications, we ensure prompt delivery and unmatched quality. For custom nickel titanium wire solutions and any further inquiries or require additional information, please feel free to contact us at baojihanz-niti@hanztech.cn.

Send Inquiry

.webp)