Here are some of the latest news about nickel titanium springs

2025-01-09 19:10:09

Results were reported in patients with mild crowding treated with modified nickel titanium spring orthotics

A study entitled "Reported Results for the Treatment of mildly congested patients with Modified orthotics using nickel titanium springs: a prospective cohort study" was published on December 22, 2024. This study evaluated patient-reported outcomes in the treatment of mild lower incisor congestion with modified nickel-titanium spring orthotics. The results showed that patients using both orthotics experienced temporary discomfort, including pain and difficulty chewing. While the modified orthotics using nickel-titanium springs created additional challenges for swallowing and speaking during the first two days of treatment, these issues were resolved over time, allowing the patient to adapt to the treatment.

China's tariff adjustment in 2025 favors nickel titanium alloy wire for surgical implants

Since January 1, 2025, China has implemented a new round of tariff adjustments. The reduction of import tariffs on nickel titanium alloy wire for surgical implants is conducive to the import of related products and promotes the application and development of nickel-titanium springs in China's medical field. It is conducive to reducing the cost of using nickel-titanium springs for medical devices, making it easier for patients to obtain, and promoting innovative progress in the medical device industry.

From 2023 to 2030, the Nitinol spring market is expected to grow significantly

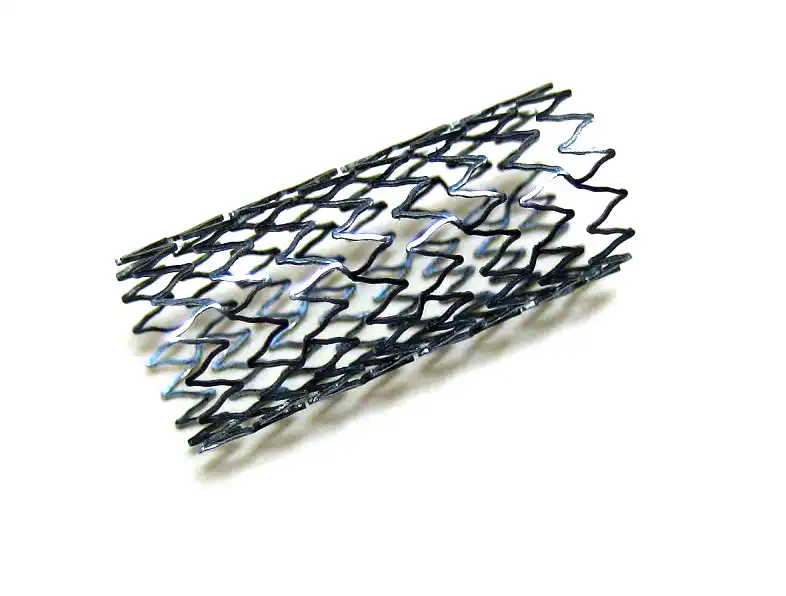

According to the market research report, the Nitinol spring market is expected to grow at a significant compound annual growth rate (CAGR) from 2023 to 2030. The increase in demand for Nitinol springs can be attributed to several factors. First, the growing popularity of Nitinol based medical devices and implants, such as stents and orthopedic anchors, is driving the demand for Nitinol springs in the medical industry. In addition, the aerospace industry is also expected to contribute significantly to the market growth as Nitinol springs are widely used in actuators, damping systems and landing gear components.

Progress in manufacturing technology of Nitinol spring

Advances in additive manufacturing technology have made it possible to produce complex Nitinol springs with better performance characteristics, further driving the growth of the market. The ability of Nitinol springs to withstand high temperatures, fatigue and excellent corrosion resistance also increases their appeal in various industries. For example, in the automotive industry, Nitinol springs are used in vehicle suspension systems and engine components to improve performance and efficiency. In electronics such as smartphones and computers, these springs are used for precise movement and connection.

A nickel titanium shape memory alloy spring tire designed by NASA for the Mars rover

NASA Glenn Research Center has developed an airless compliant tire made of nickel-titanium shape memory alloy springs for Mars rovers. The tire consists of several hundred nickel-titanium shape memory alloy coils woven into a flexible mesh structure that allows the tire to withstand high loads while also conforming to the terrain. It was tested at the Mars Life Test Facility, performing well in simulated Martian sand and withstanding rocks without difficulty. Even if the tires are deformed all the way down to the axle, they can maintain their original shape while carrying a lot of payload.

Baoji Hanz Metal Material Co., Ltd.

Gaoxin Avenue, BaoJi city, ShaanXi province China

Tel: 86-917-3258889

Mobile, Whatsapp,Wechat: +8618091719909

Email:baojihanz-niti@hanztech.cn

.webp)

.webp)

.webp)

.webp)