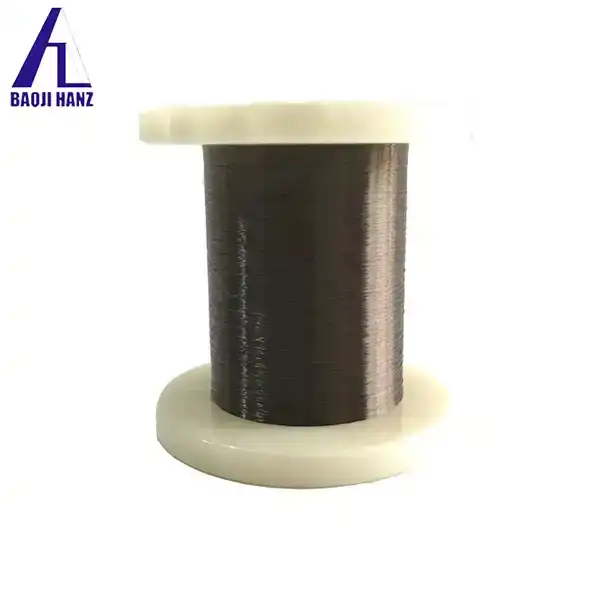

ASTM F2063 Super Elastic Nitinol Flat Wire

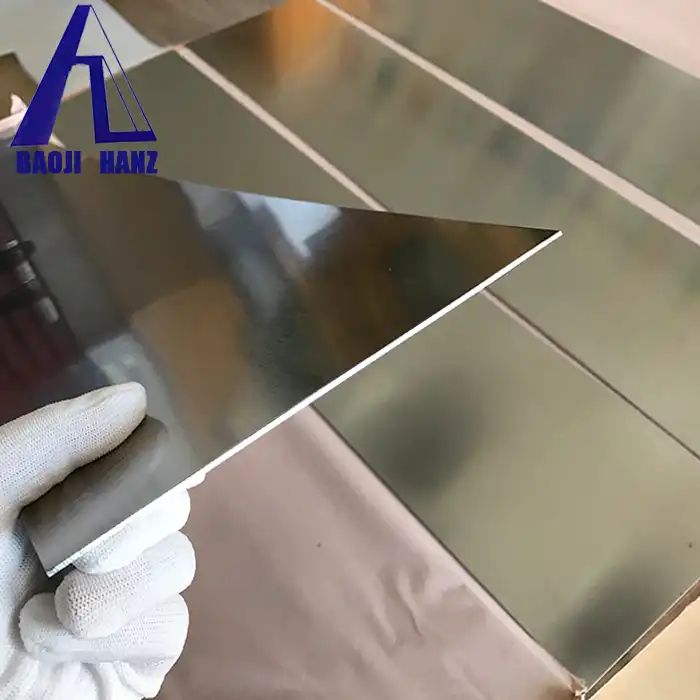

Product Details: Our Astm F2063 Super Elastic Nitinol Flat Wire is an exceptional product produced by Baoji Hanz Metal Material Co., Ltd., a renowned and reliable company in the industry. Our flat wire is crafted using advanced manufacturing techniques and undergoes strict quality control measures to guarantee its superior performance and reliability. Composed of a nickel and titanium alloy, this product showcases remarkable superelasticity, making it extremely suitable for various applications. With our commitment to excellence, we ensure that our customers receive a high-quality product that adheres to the highest standards in the industry. Trust Baoji Hanz Metal Material Co., Ltd. for your medical nitinol flat wire needs, and experience the outstanding characteristics and versatility of our product.

Specifications:

| Place of Origin | Shaanxi, China |

| Brand Name | Baoji hanz |

| Color | Black, brown, brown, blue, bright |

| Materials | Nitinol alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 45% |

| Strength | 980 Mpa |

| Processing Service | Bending, Welding, Decoiling |

| Wire Gauge | 0.02mm min |

| Tensile strength | 980 Mpa |

| Feature | Superelastic |

| Supply Status | Full annealed |

| Modulus of elasticity | Austenite 83 Gpa |

| The Max recovery stress | 185 MPa |

| Standard | ASTM F2063, Q/XB1516 |

| Certificate | ISO9001:2015 |

| Application | Guide wires Shape set parts ,Orthodontic Files .Arch wire . fishing wire .bra frames wire .glasses wire .spring wire |

| Chemical element | Af range | Available production Line | Usage | Sample |

| Nickel 55% Titanium 45% | 0℃to 100℃ | Rod&wire,Plate&sheet,Strip&foil | Medical&Industry | On stock (various specification) |

| Nickel 55% +V +Ti | ||||

| Nickel 55% +Fe +Ti | Subzero 30℃ to -5 ℃ | Rod&wire,Plate&sheet | Industry | On stock |

| Nickel 55%+Cr +Ti | (limitedspecification) | |||

| Nickel 55% +Hf +Ti | Above 100C | Ingot | Ingot | Updating |

| The production certification | ||||||

| Specification (mm) | Nitinol Superelastic wire | Typical Medical industry Application | ||||

| UTS (Mpa) | Elongation % | UpperPlateau Stress Mpa | Permanent Set after 6% strain % | Active AF | ||

| 0.1-0.3mm | ≥1100 | ≥15 | ≥480 | <0.5 | Subzero20~100 | Guide wires Shape set parts, orthodontic files, arch wire, fishing wire, bra frames wire, glasses wire,spring wire |

| 0.3~0.6mm | ≥920 | ≥15 | ≥440 | <0.5 | ||

| 0.6~3.0mm | ≥850 | ≥15 | ≥440 | <0.5 | ||

Application Areas: Our product finds extensive use in various industries such as medical, aerospace, automotive, and robotics. It is commonly utilized in:

- Medical Devices: Stents, guidewires, orthodontic archwires, surgical instruments.

- Aerospace: Actuators, sensors, control mechanisms.

- Automotive: Engine components, exhaust systems, airbag deployment mechanisms.

- Robotics: Flexible joints, grippers, actuators.

Features:

- Super Elasticity: Retains its original shape after deformation, offering superior performance in dynamic applications.

- High Strength: Provides excellent load-bearing capacity and durability.

- Biocompatible: Suitable for medical implants and devices.

- Corrosion Resistance: Maintains its integrity even in harsh environments.

Production Technology: Our Astm F2063 Super Elastic Nitinol Flat Wire is meticulously crafted using cutting-edge processing techniques, such as hot rolling, cold rolling, and heat treatment. These advanced methods guarantee exceptional consistency in both dimensions and mechanical properties across the entire wire. By employing hot rolling, we can achieve precise shaping and thickness control, resulting in a flat wire with uniform width and thickness throughout its length. The subsequent cold rolling process further refines the wire's surface finish and enhances its mechanical strength. To optimize the wire's superelasticity, a meticulous heat treatment process is employed, ensuring that it possesses the desired shape memory effect and exceptional flexibility. At every step of the manufacturing process, we implement stringent quality control measures to ensure that our product meets the highest standards of quality and reliability. Choose our flat nitinol wire for its outstanding performance and consistency, and experience the unparalleled benefits it brings to your applications.

Quality Control: At Baoji Hanz Metal Material Co., Ltd., we place utmost importance on maintaining the highest quality standards. Our commitment to quality is reflected in our stringent quality control procedures implemented throughout every phase of production. Starting with a thorough inspection of raw materials, we ensure that only the finest materials are utilized in the manufacturing process. During production, our medical nitinol flat wire undergoes rigorous testing to assess its mechanical properties, dimensional accuracy, and surface finish. This meticulous evaluation guarantees that each wire meets the required specifications and performs consistently. Furthermore, our final product testing ensures that our product delivers reliable performance and durability. By adhering to these comprehensive quality control measures, we instill confidence in our customers, knowing that they receive a superior product that meets their exact requirements. Trust Baoji Hanz Metal Material Co., Ltd. for exceptional quality flat nitinol wire that exceeds expectations in performance and reliability.

FAQs:

- What is the maximum operating temperature for Astm F2063 Super Elastic Nitinol Flat Wire?

- The maximum operating temperature is approximately 300°C.

- Is the flat wire suitable for sterilization?

- Yes, it is compatible with common sterilization methods such as autoclaving and gamma irradiation.

- Can the dimensions be customized?

- Yes, we offer custom manufacturing services to meet specific customer requirements.

Final Details: Baoji Hanz Metal Material Co., Ltd. is a professional manufacturer and supplier of it with a large inventory and complete certificates. For inquiries or to place an order, please contact us at baojihanz-niti@hanztech.cn.

Send Inquiry

.webp)

.webp)