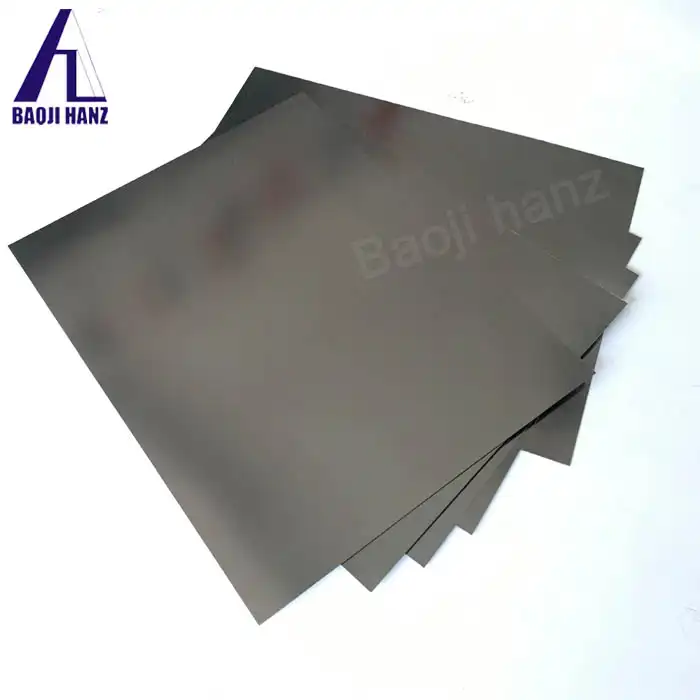

Product Introduction: Rope Nitinol Wire

Our rope nitinol wire is a novel material that makes use of the amazing shape-memory properties of a nickel-titanium alloy. It is ideal for applications requiring exceptional flexibility and resilience due to its unique composition's ability to return to its original shape after being deformed. Our nitinol wire, made using cutting-edge manufacturing methods and precise control over the alloy's composition, provides unparalleled performance in robotics, medical devices, and aerospace engineering applications. It is an outstanding choice for industries with stringent requirements due to its capacity to withstand multiple cycles of deformation while maintaining its original properties.

In addition, our product has an impressive tensile strength and resistance to fatigue, ensuring longevity and dependability even in the harshest conditions. A product with superelasticity and high levels of stress resistance without permanent deformation is the result of our meticulous manufacturing process's manipulation of the wire's microstructure for optimal performance. In applications like safety harnesses and sports equipment where shock absorption and impact resistance are crucial, these properties are invaluable. In essence, our nitinol fishing wire exemplifies versatility and excellence by providing a solution that satisfies the stringent requirements of contemporary industries while consistently delivering superior performance.

Specifications

| Place of Origin | Shaanxi, China |

| Brand Name | Baoji hanz |

| Wire Gauge | Above Dia. 0.3mm |

| Color | Nature, Amber or blue |

| AF | -20℃~100℃ |

| Strength | 1000 Mpa |

| surface | Black Polished Pickling |

| Materials | Nitinol Ti-Ni Alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 44% |

| Ni (Min) | 54% |

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Feature | Superelastic, high strength |

| Standard | ASTMF2063 |

| Application | Fishing,Fishing leaders |

| Shape | Round |

|

|

Application Areas

Numerous industries utilize our rope nitinol wire extensively, including:

- Medical Equipment: Used in orthodontics, cardiovascular implants, and minimally invasive surgical procedures.

- Automotive: Used in vibration damping systems, actuators, and sensors.

- Aerospace: Utilized in components of aircraft, such as landing gear systems, antennas, and actuators.

- Robotics: For precise motion control and manipulation in robotic systems.

- Electronics for Consumers: incorporated into wearable devices, actuators, and smart appliances for enhanced functionality.

Features

- Effect of Shape Memory: Exhibits the capacity to revert to its original shape after being deformed.

- Superelasticity: Possesses a high degree of elasticity and little permanent deformation when stressed.

- Biocompatibility: Excellent corrosion resistance and biocompatibility make it suitable for medical applications.

- Temperature Dependence: Temperature-responsive, allowing for dynamic functionality in a variety of settings.

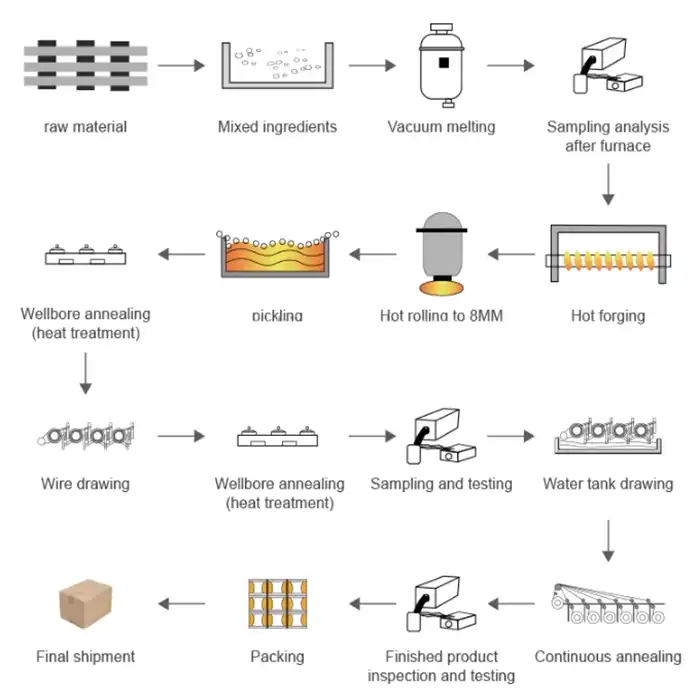

Production Technology

Advanced manufacturing techniques are used to produce our nitinol twisted wire, which includes:

- Combining and Melting: To achieve precise compositions, high-purity nickel and titanium are melted and alloyed.

- Rolling Hot: The alloy is rolled hot into the desired diameters and shapes for the wire.

- Cold Employment: In order to improve its flexibility and strength, wire is cold worked.

- Heat therapy: Microstructure is improved and shape memory properties are added through controlled heat treatment processes.

- Care for the Surface: To meet specific requirements, optional surface treatments, such as coating or polishing, can be applied.

Quality Control

To ensure product consistency and quality, we adhere to stringent quality control measures throughout the manufacturing process. Our quality control procedures include:

- Examining the Material: thorough examination of the chemical composition and purity of the raw materials.

- Analytical Dimensions: precision in measuring the diameter, length, and surface finish of the wire.

- Tests on the Mechanical: Checking for mechanical properties like tensile strength, elasticity, and the ability to remember its shape.

- Examining the Surface: Surface analysis and visual inspection to find any flaws or irregularities

Company and equipment:

Production process:

Shipping:

FAQs:

-

What is nitinol wire?

-

Nitinol wire is a nickel-titanium alloy known for its unique shape memory and superelastic properties.

-

What are the primary applications of rope nitinol wire?

-

The product is widely used in medical devices, automotive components, aerospace applications, robotics, and consumer electronics.

-

Is rope nitinol wire biocompatible?

-

Yes, it exhibits excellent biocompatibility, making it suitable for medical implants and devices.

Final Details

Rope nitinol wire is produced and sold by Baoji Hanz Metal Material Co., Ltd., a leading manufacturer and supplier. Through our cutting-edge manufacturing facilities, extensive inventory, and comprehensive certifications, we are committed to providing our global customers with high-quality goods and exceptional service.

Please do not hesitate to contact us at baojihanz-niti@hanztech.cn if you require our product for your applications. We are eager to meet your requirements and offer you the best nickel titanium wire solutions.

Send Inquiry

.webp)

.webp)

.webp)