Baoji Hanz Metal Material Co., Ltd.: Your Trusted Nitinol Foil Strip Manufacturer & Supplier

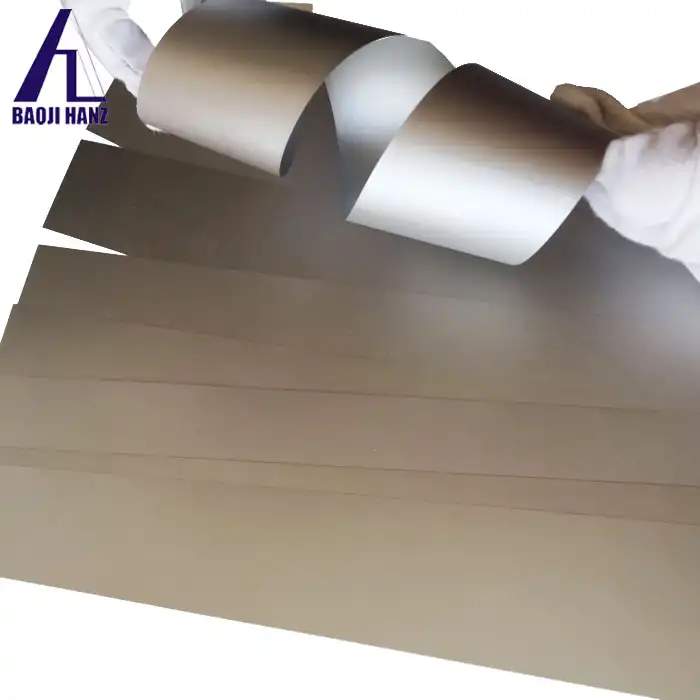

Nitinol foil strip is a novel and profoundly flexible material known for its exceptional properties, making it fundamental in different enterprises. Nitinol, an amalgam of nickel and titanium, stands apart for its shape memory and superelastic attributes. These properties empower the material to get back to its unique shape after twisting, an element profoundly important in applications requiring strength and adaptability.

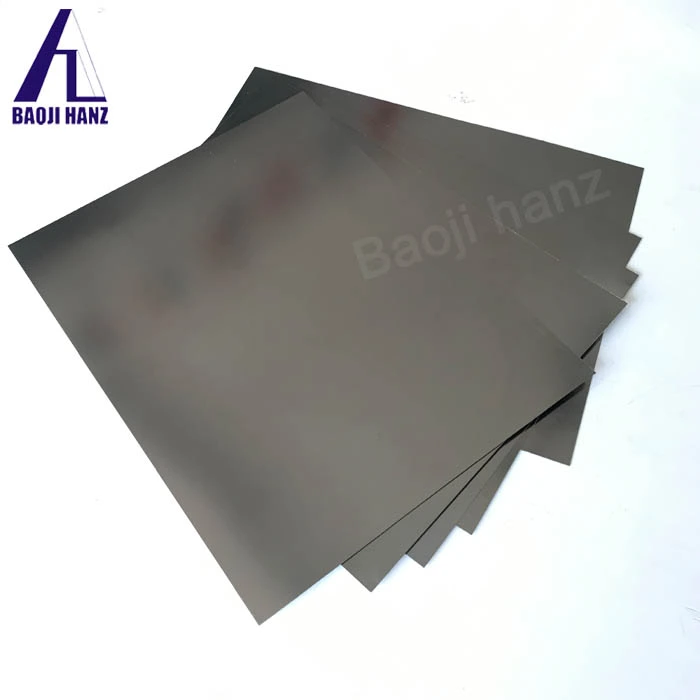

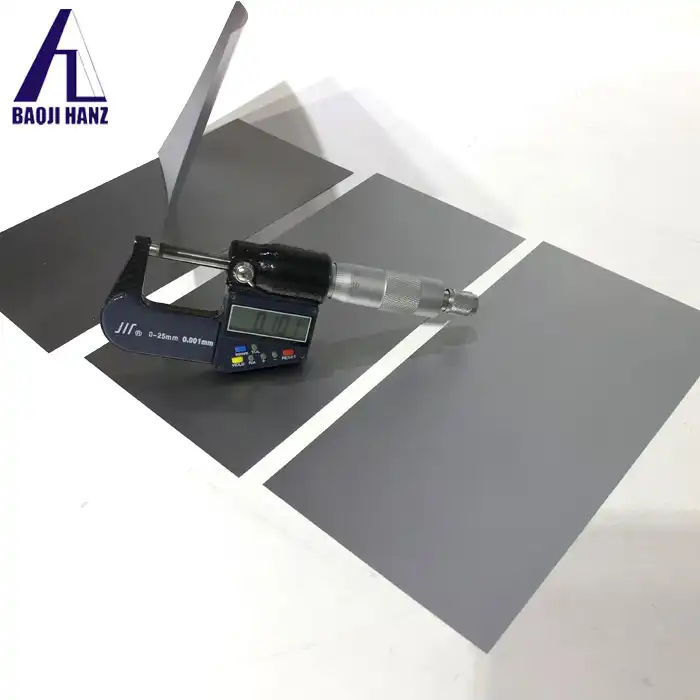

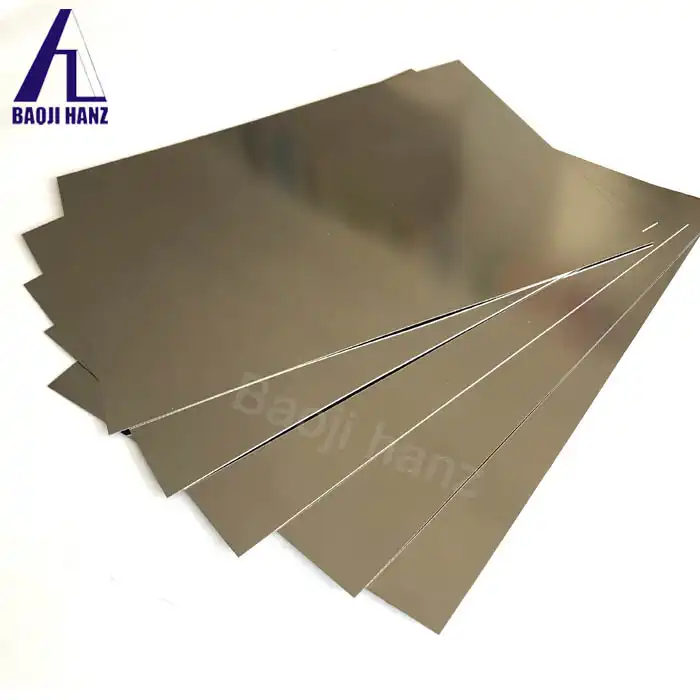

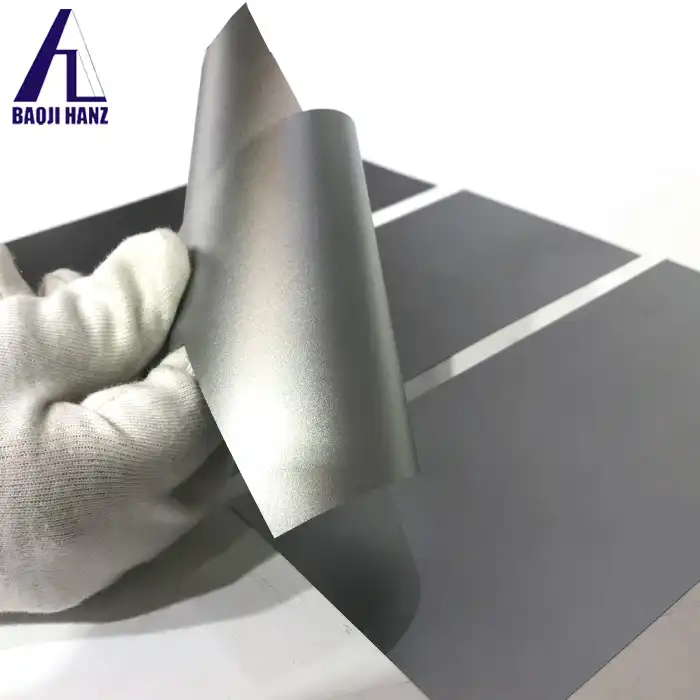

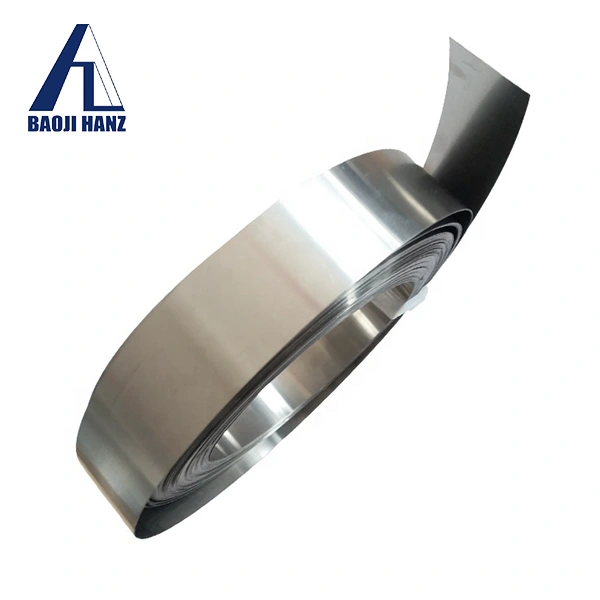

The product is regularly accessible in a scope of thicknesses, widths, and lengths, adjustable to meet explicit necessities. Its thickness can differ from micrometers to a few millimeters, taking care of both fragile and vigorous applications. The outer layer of the foil is smooth and cleaned, guaranteeing fantastic weariness opposition and biocompatibility, which is critical for clinical applications.

|

|

|

Nitinol Foil Strip Specifications

| Place of Origin | Shaanxi, China |

| Brand Name | Baoji hanz |

| Color | Bright surface |

| Materials | Nitinol alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 45% |

| Processing Service | Bending, Welding, Decoiling |

| Feature | Superelastic |

| Supply Status | Full annealed |

| Standard | ASTM F2063-18 |

| Certificate | ISO9001:2015 |

| Application | Cutting Processing Service |

| Chemical element | Af range | Available production Line | Usage | Sample |

| Nickel 55% Titanium 45% | 0℃to 100℃ | Rod&wire,Plate&sheet,Strip&foil | Medical&Industry | On stock (various specification) |

| Nickel 55% +V +Ti | ||||

| Nickel 55% +Fe +Ti | Subzero 30℃ to -5 ℃ | Rod&wire,Plate&sheet | Industry | On stock |

| Nickel 55%+Cr +Ti | (limitedspecification) | |||

| Nickel 55% +Hf +Ti | Above 100C | Ingot | Ingot | Updating |

| Mechanical Properties | ||||

| Thickness | UTS | Elongation | Upper Plateau Stress | Active Af |

| mm | σb MPa (min.) | δ % (min) | σload MPa (min.) | ℃ |

| 0.1 ~ 0.3 | 1100 | 15 | 480 | |

| 0.3 ~ 0.6 | 920 | 15 | 440 | - 20 ~ 100 ℃ |

| 0.6 ~ 6.0 | 850 | 15 | 440 | |

| Tolerance | |

| Nominal Thickness in mm | Permissible Variation from Nominal in mm |

| 6.00 ~ 1.00 | ± 0.05 |

| 1.00 ~ 0.26 | ± 0.03 |

| 0.26 ~ 0.15 | ± 0.02 |

| 0.15 ~ 0.10 | ± 0.01 |

Application Areas

Products are renowned for their unique properties, making them highly valuable in various application areas. Nitinol, an alloy of nickel and titanium, exhibits remarkable shape memory and superelasticity, which are key to its diverse uses.

Medical Devices: One of the primary application areas for products is in the medical field. Their biocompatibility and ability to return to a predetermined shape after deformation make them ideal for minimally invasive surgical tools, stents, and guidewires. For instance, in cardiovascular surgeries, Nitinol stents can be compressed for insertion into the body and then expand at the target site, providing crucial support to blood vessels.

Consumer Electronics: Products are also used in consumer electronics due to their flexibility and resilience. They are found in various components such as flexible displays, actuators, and connectors. The durability and ability to withstand repeated bending and flexing without losing functionality make them perfect for modern electronic devices that require compact and reliable components.

Aerospace and Defense: In the aerospace and defense sectors, Buy it contribute to advanced engineering solutions. Their superelasticity and high fatigue resistance are advantageous in the manufacturing of critical components like actuators, sensors, and fasteners. These properties help in reducing maintenance needs and improving the longevity and reliability of aircraft and defense equipment.

Automotive Industry: The automotive industry benefits from Nitinol’s unique characteristics as well. Products are used in applications such as temperature control systems, sensors, and actuators within vehicles. Their ability to withstand high temperatures and stresses makes them suitable for enhancing the performance and efficiency of automotive systems.

Robotics and Automation: In the realm of robotics and automation, products are pivotal in the development of responsive and adaptable components. Their ability to undergo significant deformation and return to their original shape is exploited in creating flexible robotic joints, grippers, and other actuators that mimic biological movements, enhancing the functionality and versatility of robotic systems.

Sporting Goods: Nitinol's durability and flexibility are also utilized in sporting goods. Equipment such as eyeglass frames, golf club shafts, and other high-performance gear leverage it for their ability to endure stress and return to their original shape, providing a combination of strength and flexibility that enhances the user experience.

Energy Sector: Finally, in the energy sector, products play a role in the development of advanced energy systems. Their application in energy harvesting and conversion devices, such as thermoelectric generators, demonstrates their potential in improving energy efficiency and developing sustainable technologies.

Features

- Shape Memory Effect: Returns to a predetermined shape when heated.

- Superelasticity: Exhibits significant elastic deformation under stress.

- Biocompatibility: Safe for use in medical implants.

- Corrosion Resistance: Maintains integrity in harsh environments.

Production Technology

Nitinol foil strips are a specialized form of production technology, essential in various high-tech applications due to their unique properties. Nitinol, an alloy of nickel and titanium, exhibits shape memory and superelasticity, making it highly valuable in industries such as medical devices, aerospace, and robotics. The production of products involves precise metallurgical processes to ensure the material's consistent quality and performance.

Manufacturing begins with the melting of high-purity nickel and titanium, followed by casting into ingots. These ingots undergo multiple stages of hot and cold rolling to achieve the desired thinness and mechanical properties. Advanced heat treatment processes are then applied to set the shape memory characteristics and optimize superelastic performance. Surface treatments, such as polishing and coating, are often employed to enhance the foil's biocompatibility and resistance to corrosion, crucial for medical implants and other demanding applications.

Quality control is stringent, involving various testing methods like differential scanning calorimetry (DSC) to verify phase transformation temperatures and tensile testing to assess mechanical properties. The precise control over alloy composition and processing parameters ensures that products meet the rigorous standards required for their specialized uses, enabling innovation and reliability in cutting-edge technological fields.

Quality Control

Ensuring the quality of nitinol superelastic foil strips is crucial due to their specialized applications in various industries, including medical devices and aerospace. The quality control process involves several steps to guarantee the material meets stringent standards.

Firstly, the raw materials are carefully selected and inspected to ensure they meet the required specifications. This includes verifying the composition of nickel and titanium, as the precise ratio is critical for the alloy’s shape memory and superelastic properties.

Next, during the manufacturing process, the foil strips undergo rigorous testing for thickness uniformity, surface finish, and mechanical properties. Techniques such as laser micrometry and scanning electron microscopy are employed to detect any deviations or defects.

Additionally, thermal cycling tests are performed to ensure the Nitinol retains its shape memory functionality after repeated use. These tests involve heating and cooling the material to observe its transformation temperatures and recovery stress.

FAQ

Q: What are the typical dimensions of your products?

A: Our Nitinol Foil Strip is available in various thicknesses and widths to suit specific application requirements.

Q: Is your product resistant to corrosion?

A: Yes, our foil strip exhibits excellent corrosion resistance, making it suitable for use in challenging environments.

Contact Us

Baoji Hanz Metal Material Co., Ltd. is a leading manufacturer and supplier of Nitinol Foil Strip. With our state-of-the-art factory, extensive inventory, and complete certifications, we guarantee fast delivery and exceptional customer service. For inquiries or to request a quote, please contact us at baojihanz-niti@hanztech.cn.

.webp)