Product Introduction

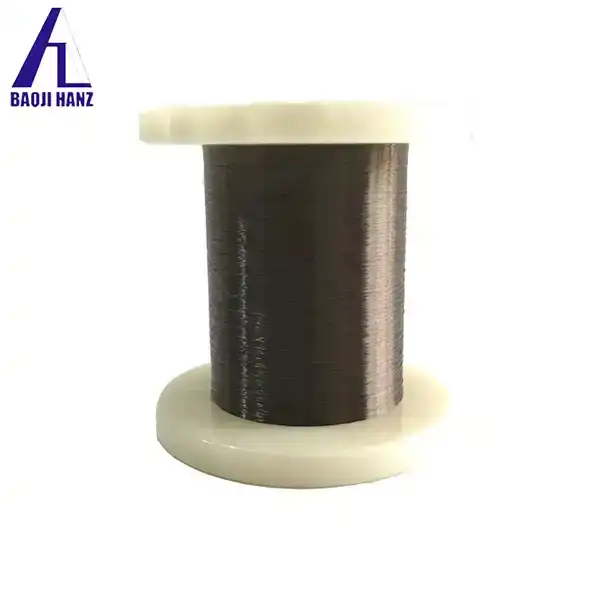

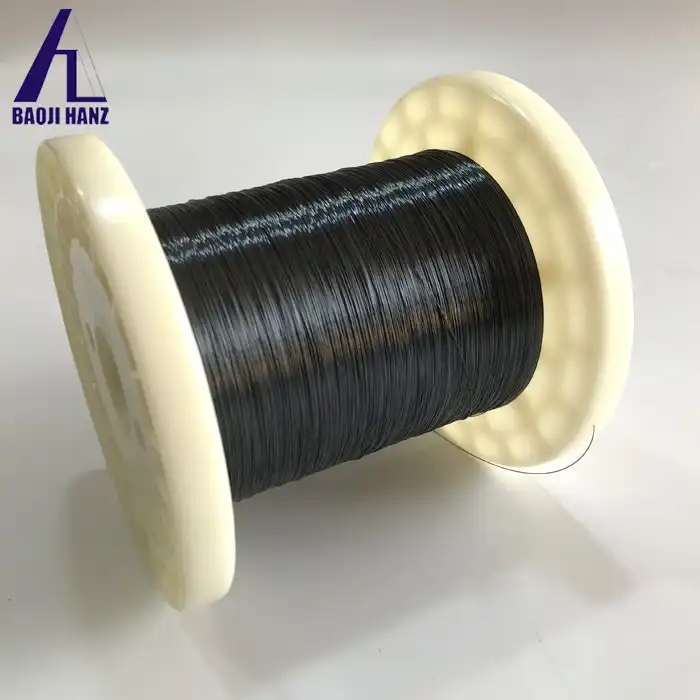

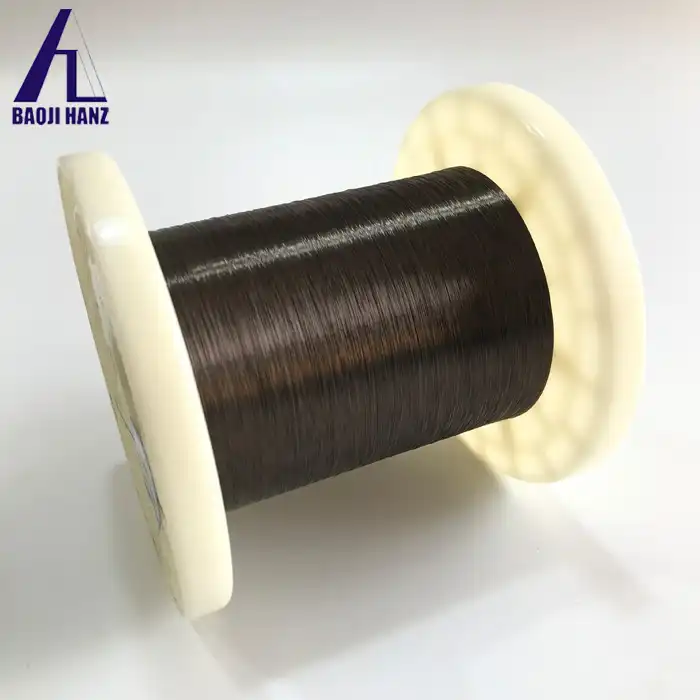

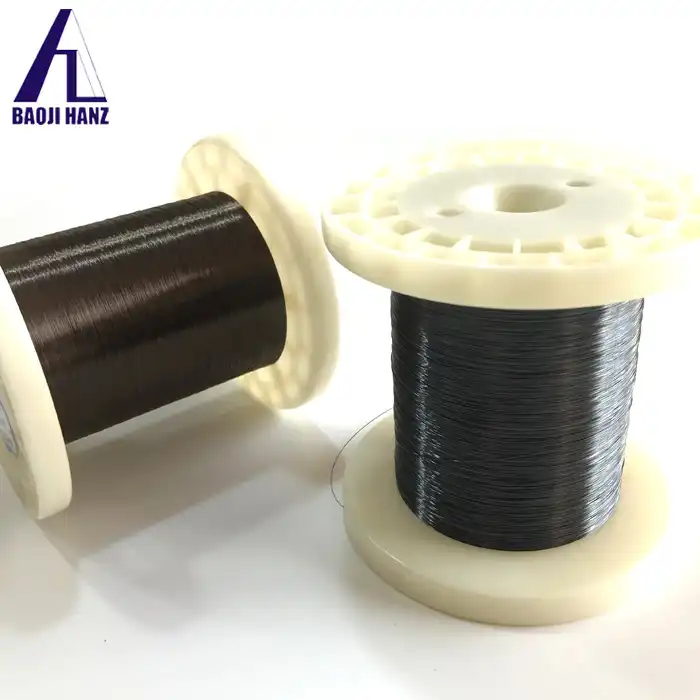

Our Nickel Titanium Alloy Wire is designed for industries that demand superior performance, flexibility, and reliability. Baoji Hanz Metal Material Co., Ltd. offers high-quality nickel titanium wires, perfect for medical, industrial, and research applications. With over 10 years of experience, we provide products that meet international standards, ensuring precision, durability, and the desired mechanical properties.

Whether you need shape memory alloy or superelastic wires, our nickel titanium alloy is tailored for critical applications in medical devices, surgical tools, and advanced research projects.

Product Specifications

| Specification | Details |

|---|---|

| Diameter Range | 0.025mm - 0.5mm |

| Shape Memory Transition Temp | -20°C to +100°C |

| Surface Finish | Bright, Black Oxide, Polished |

| Tensile Strength | 800 MPa - 1900 MPa |

| Elongation | >10% |

| Certifications | ASTM F2063 |

| MOQ | 1 kg or 100meter |

| Stock Availability | Large amount of ready stock |

Product Advantages

- High Strength & Flexibility: The superelastic nature of nickel titanium ensures it can undergo large deformations without permanent damage.

- Shape Memory Effect: Designed to revert to its original shape after deformation, making it perfect for medical devices like stents.

- Corrosion Resistance: Excellent resistance to corrosive environments, ideal for both medical and industrial applications.

- Biocompatibility: Meets stringent medical standards, safe for use in implants and other body-contact applications.

- Customizable: Wires can be manufactured to specific requirements regarding diameter, length, and performance.

Technical Features

- Superelastic Properties: Allowing for up to 8% strain recovery.

- Shape Memory Alloy Behavior: Our wires return to their original form when exposed to specific temperatures.

- Precision Manufacturing: Each wire undergoes rigorous testing to ensure uniformity and consistency.

Product Application

Nickel titanium alloy wire has emerged as a transformative material across multiple industries, renowned for its unique properties and versatility. In the medical field, this alloy is integral to the production of stents and guidewires, enhancing the effectiveness of minimally invasive procedures. Additionally, it plays a crucial role in dental braces, providing optimal flexibility and support for orthodontic treatments, as well as in surgical tools where precision and reliability are paramount. In the aerospace sector, nickel titanium wire is utilized in actuators and high-performance components, contributing to the development of advanced systems that require exceptional durability and resilience under varying conditions. Moreover, the biotechnology landscape benefits significantly from this alloy, as it is employed in instruments that necessitate high precision and a remarkable memory effect, enabling innovative applications in diagnostics and treatment. Research institutions are also leveraging nickel titanium wire for the development of pioneering technologies centered around smart materials, fostering breakthroughs that could redefine various applications in science and engineering. Collectively, these diverse applications highlight the ultimate potential of the wire to drive innovation and enhance performance across multiple sectors.

OEM Services

We offer complete OEM services:

- Custom designs based on your specifications.

- Flexible MOQ to accommodate both small and large orders.

- Rapid prototyping and sample testing.

- All products are backed by certifications and strict quality control Processes.

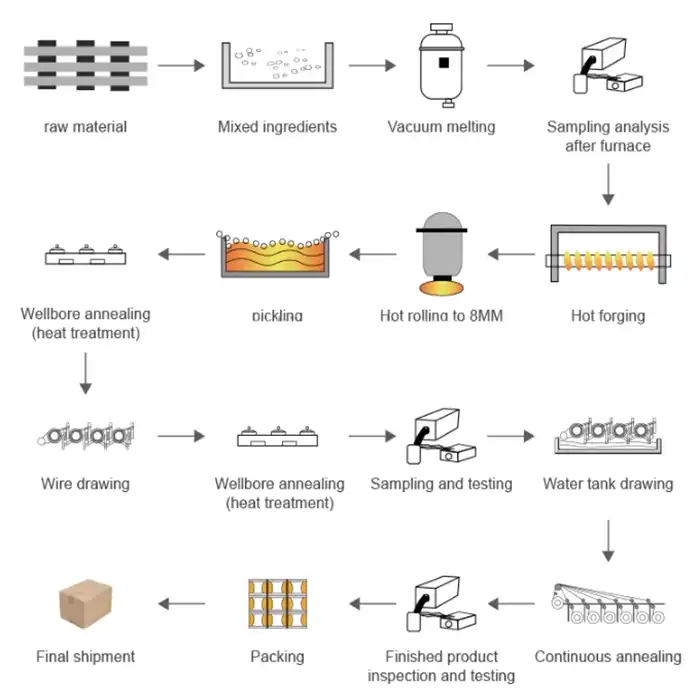

Nickel Titanium Alloy Wire Of Production Process

Nickel Titanium Alloy Wire Of ShippingFAQ

Q1: Can you provide a free sample for testing?

A: No, Sorry, due to category limitations, we are unable to provide free samples for testing..

Q2: What certifications do your nickel titanium wires have?

A: Our wires are ISO9001:2015, ensuring international quality and safety standards.

Q3: Can I order custom-sized wires?

A: Absolutely! We can customize the diameter, length, and mechanical properties to suit your specific application.

Q4: How do you ensure quality during production?

A: We employ advanced R&D and testing equipment to maintain strict quality controls from raw material selection to the final product.

Q5: What is the minimum order quantity?

A: Our MOQ is 1kg or 100meter, making it easy for you to order in small or large quantities.

Contact Us

For inquiries and more details about our Nickel Titanium Alloy Wire, please contact us at baojihanz-niti@hanztech.cn. We look forward to working with you to meet your material needs!

Send Inquiry

.webp)

.webp)

.webp)