What advantages does nitinol foil have over traditional materials?

2024-10-18 22:31:11

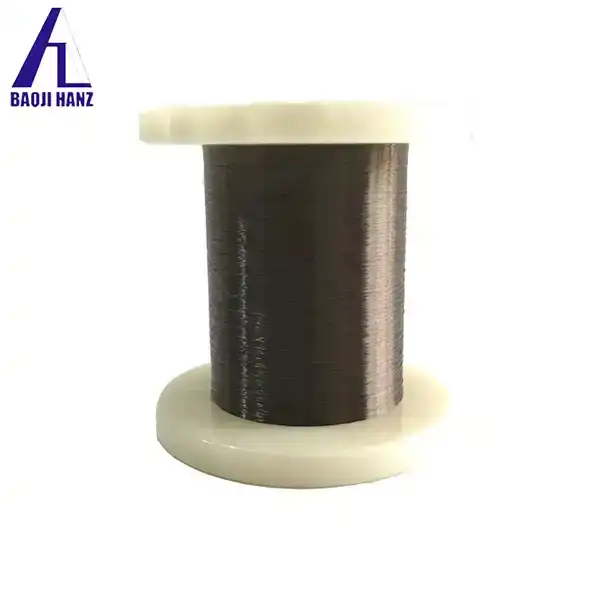

Super elastic nitinol foil,a remarkable advancement in material science, has been revolutionizing various industries with its unique properties. This product, composed of nickel and titanium, offers a wide array of advantages over conventional materials. From its shape memory capabilities to its superelastic nature, nitinol foil has opened up new possibilities in fields such as aerospace, medical devices, and robotics. In this comprehensive exploration, we'll delve into the fascinating world of nitinol foil, examining its distinctive characteristics, comparing it with traditional materials, and uncovering the myriad ways it's reshaping modern engineering and design practices.

The Unique Properties of Nitinol Foil

Shape Memory Effect: A Game-Changer in Material Science

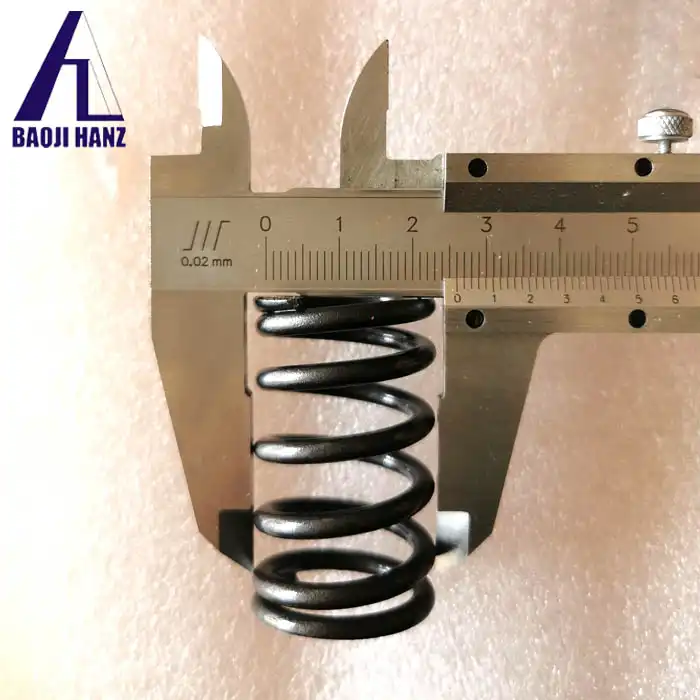

One of the most captivating properties of the product is its shape memory effect. This phenomenon allows the material to "remember" and return to its original shape after deformation when exposed to a specific temperature. This characteristic sets nitinol foil apart from traditional materials, which typically maintain their deformed state after being subjected to stress. The shape memory effect of super elastic nitinol foil is rooted in its unique crystalline structure. At lower temperatures, the material exists in a martensite phase, which is relatively soft and easily deformable. When heated above its transformation temperature, nitinol transitions to an austenite phase, recovering its original shape with considerable force. This ability to switch between phases and recover its form makes nitinol foil an ideal candidate for applications requiring controlled, repeatable movements or self-adjusting mechanisms.

Superelasticity: Pushing the Boundaries of Flexibility

Another remarkable attribute of our product is its superelasticity. This property allows the material to undergo large deformations without permanent damage, returning to its original shape once the stress is removed. Unlike traditional materials that may experience plastic deformation or breakage under similar conditions, nitinol foil can withstand substantial strain while maintaining its integrity. The superelastic behavior of nitinol foil is particularly valuable in applications that demand high flexibility and resilience. For instance, in the medical field, nitinol-based instruments can navigate through complex anatomical structures without risking permanent deformation or breakage. This characteristic also makes nitinol foil an excellent choice for dynamic structures in aerospace and robotics, where components must withstand repetitive stress cycles without fatigue.

Biocompatibility: Bridging the Gap Between Materials and Biology

Nitinol foil's biocompatibility is another significant advantage over many traditional materials. Its ability to coexist harmoniously with living tissues without causing adverse reactions has made it a preferred material in medical implants and devices. This property is particularly crucial in applications where long-term contact with the human body is necessary. The biocompatibility of nitinol foil stems from its resistance to corrosion and its ability to form a stable oxide layer on its surface. This protective layer prevents the release of potentially harmful ions into the surrounding tissues, making nitinol foil a safer alternative to some conventional biomaterials. Additionally, the material's mechanical properties closely mimic those of human bone and soft tissues, further enhancing its suitability for medical applications.

Comparing Nitinol Foil to Traditional Materials

Nitinol vs. Stainless Steel: A New Era of Flexibility

When comparing super elastic nitinol foil to traditional materials like stainless steel, the differences become starkly apparent. While stainless steel has long been a go-to material for many applications due to its strength and corrosion resistance, it lacks the unique properties that make nitinol foil so versatile. Nitinol foil's superelasticity allows it to undergo much larger deformations than stainless steel without permanent damage. This characteristic is particularly advantageous in applications requiring repeated bending or flexing, where stainless steel might experience fatigue or breakage. Moreover, nitinol's shape memory effect enables it to return to its original form after deformation, a feature that stainless steel simply cannot replicate.

Nitinol vs. Polymers: Combining Strength and Flexibility

Polymers are another class of materials that nitinol foil often outperforms in certain applications. While polymers offer excellent flexibility and are widely used in various industries, they typically lack the strength and temperature resistance of nitinol foil. Our product combines the flexibility of polymers with the strength of metals, offering a unique balance of properties. This combination allows for the creation of components that can withstand high stress while maintaining the ability to flex and recover their shape. In contrast, many polymers would experience permanent deformation or failure under similar conditions.

Nitinol vs. Traditional Shape Memory Alloys: Pushing the Boundaries

While nitinol is not the only shape memory alloy available, it often outperforms other materials in this category. Compared to traditional shape memory alloys like copper-aluminum-nickel or iron-manganese-silicon, nitinol offers superior mechanical properties and a wider range of potential applications. The transformation temperature of the product can be precisely controlled through its composition and processing, allowing for greater flexibility in design and application. This level of control is often more challenging to achieve with other shape memory alloys. Additionally, nitinol's excellent corrosion resistance and biocompatibility give it a significant edge in medical and marine applications, where these properties are crucial.

Applications and Future Prospects of Nitinol Foil

Revolutionary Medical Devices: Enhancing Patient Care

The medical field has embraced super elastic nitinol foil for its unique properties, leading to significant advancements in patient care. Cardiovascular stents made from nitinol foil can be compressed into a small diameter for minimally invasive insertion, then expand to their full size once in place. This self-expanding capability reduces the risk of complications and improves patient outcomes. Orthodontic archwires crafted from nitinol foil provide consistent, gentle force over extended periods, resulting in more efficient and comfortable tooth movement. The material's superelasticity allows these wires to maintain their effectiveness even as teeth shift, reducing the need for frequent adjustments.

Aerospace Innovations: Lightweight and Adaptive Structures

In the aerospace industry, the advantages of the product are driving innovations in aircraft design and space exploration. The material's high strength-to-weight ratio makes it an excellent choice for lightweight components that can withstand the extreme conditions of flight and space travel. Shape memory nitinol foil is being used to create adaptive aircraft structures that can change shape in response to different flight conditions. These morphing wings and control surfaces can optimize aerodynamic performance across a range of speeds and altitudes, potentially improving fuel efficiency and maneuverability.

Emerging Technologies: Shaping the Future

As research into the product continues, new applications are constantly emerging. In the field of robotics, nitinol-based actuators are enabling the development of more lifelike and efficient artificial muscles. These actuators can produce smooth, natural movements while requiring less energy than traditional motor-driven systems. The automotive industry is exploring nitinol foil for various applications, including impact-absorbing structures and self-repairing body panels. The material's ability to absorb and dissipate energy could enhance vehicle safety, while its shape memory properties could allow dents and deformations to be easily repaired.

Conclusion

Super elastic nitinol foil stands out as a remarkable material, offering a unique combination of properties that surpass traditional materials in many applications. Its shape memory effect, superelasticity, and biocompatibility open up new possibilities across various industries, from medicine to aerospace. As research continues and new applications emerge, nitinol foil is poised to play an increasingly important role in shaping the future of technology and engineering. If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1. Duerig, T. W., & Pelton, A. R. (2018). Nitinol: The Material and Its Properties. In Nitinol: Shape Memory Alloys for Biomedical Applications (pp. 3-29). Woodhead Publishing.

2. Jani, J. M., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

3. Morgan, N. B. (2004). Medical shape memory alloy applications—the market and its products. Materials Science and Engineering: A, 378(1-2), 16-23.

4. Mohd Jani, J., Leary, M., & Subic, A. (2017). Designing shape memory alloy linear actuators: A review. Journal of Intelligent Material Systems and Structures, 28(13), 1699-1718.

5. Lagoudas, D. C. (Ed.). (2008). Shape memory alloys: modeling and engineering applications. Springer Science & Business Media.

6. Sun, L., Huang, W. M., Ding, Z., Zhao, Y., Wang, C. C., Purnawali, H., & Tang, C. (2012). Stimulus-responsive shape memory materials: a review. Materials & Design, 33, 577-640.

_1730169709694.webp)

.webp)

.webp)