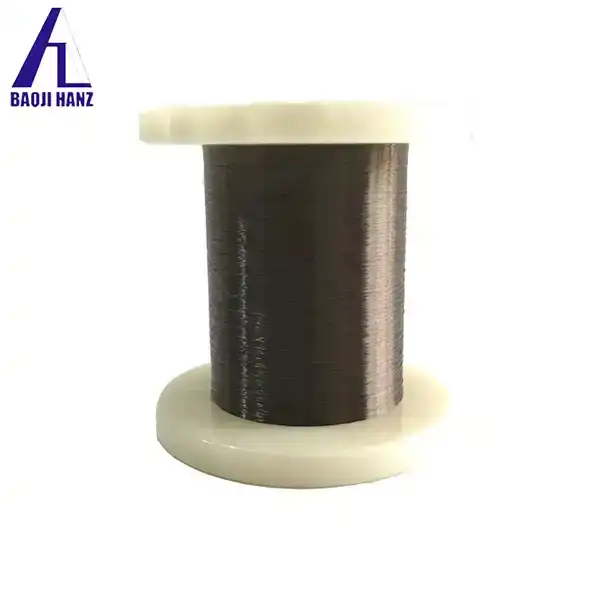

What is nitinol wire?

2024-07-29 17:58:00

Nitinol wire is a type of shape memory alloy primarily composed of nickel (Ni) and titanium (Ti). Known for its unique properties, nitinol can undergo deformation at lower temperatures and return to its original shape when heated above a specific transformation temperature. This ability is due to a reversible phase transformation between austenite and martensite phases. Nitinol wire exhibits superelasticity, allowing it to endure large deformations and recover without permanent damage. These characteristics make nitinol wire valuable across various industries, including aerospace, medical devices, robotics, and consumer electronics, where precise control, resilience, and shape recovery are essential requirements.

How is Nitinol Wire Made?

Nitinol wire is manufactured through a specialized process involving several key steps:

Alloying: Nickel (Ni) and titanium (Ti) are melted together in precise proportions, typically around equal atomic percentages, to form a uniform alloy known as NiTi.

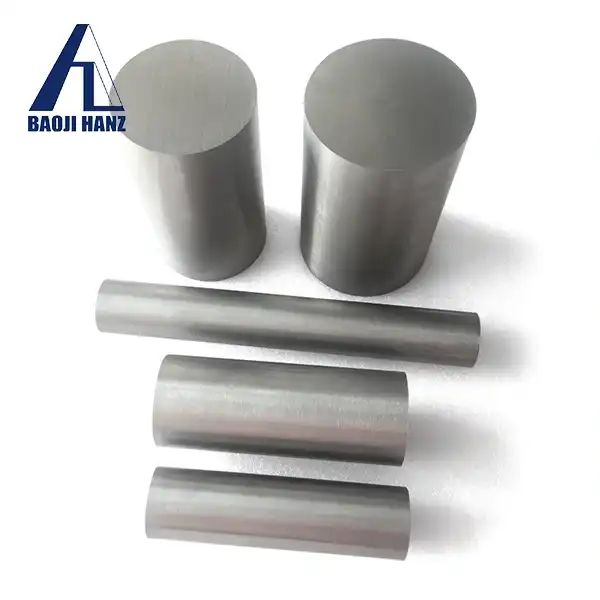

Hot Working: The alloy undergoes hot working processes such as rolling or extrusion to form an initial shape, such as rods or tubes. This step helps align the crystal structure and improve mechanical properties.

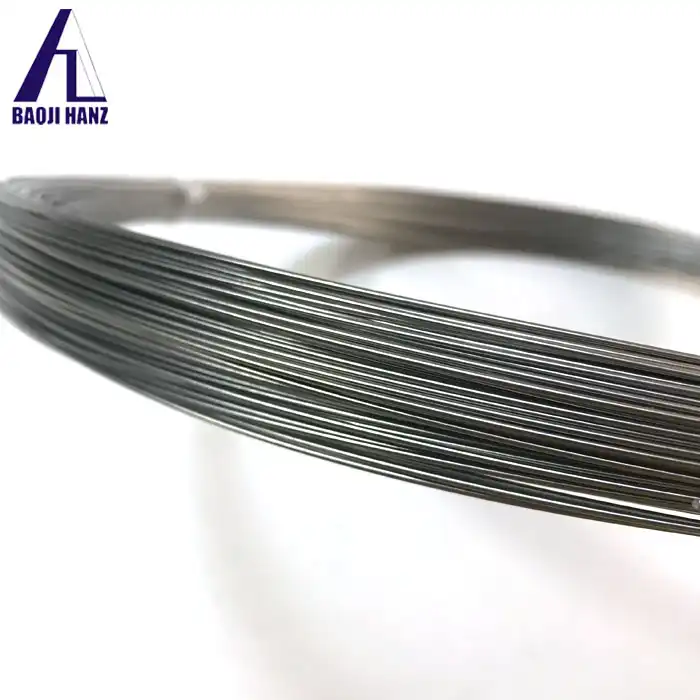

Cold Working: The material is then cold worked through processes like drawing through dies to reduce its diameter and further refine its mechanical properties, enhancing strength and ductility.

Heat Treatment: Critical to its unique properties, the wire is heat-treated to set its shape memory and superelastic characteristics. This involves heating the wire to a specific temperature and then cooling it under controlled conditions to stabilize the desired phase structure (austenite or martensite).

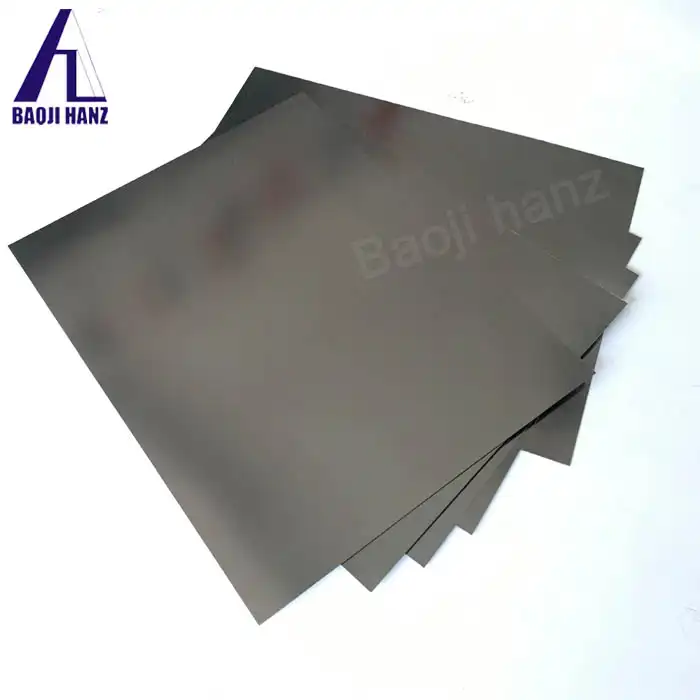

Final Processing: After heat treatment, the wire may undergo additional processes such as cutting to length, surface polishing, or coating to enhance properties like corrosion resistance or biocompatibility.

Quality Control: Throughout the manufacturing process, rigorous quality control measures ensure that the nitinol wire meets precise specifications for mechanical properties, dimensional accuracy, and performance requirements.

This manufacturing process results in nitinol wire with its distinctive properties, making it suitable for diverse applications in industries such as aerospace, medical devices, robotics, and consumer electronics.

What are the Applications of Nitinol Wire?

Nitinol wire finds diverse applications across various industries due to its unique properties:

Medical Devices: Used in stents for expanding and maintaining vessel patency, guidewires for navigating through blood vessels, and orthodontic wires for teeth alignment.

Aerospace: Employed in actuators for precise control mechanisms, deployable structures such as solar arrays, and adaptive components in aircraft wings.

Robotics: Utilized as actuators for precise movements in robotic systems, enhancing flexibility and control in applications requiring dynamic responses.

Consumer Electronics: Used in hinges and flexible connectors due to its shape memory and durability, ensuring reliable performance in devices like smartphones and laptops.

Automotive: Applied in components such as actuators and sensors that benefit from shape memory properties, contributing to improved functionality and efficiency.

Industrial Applications: Used in various industrial tools and equipment requiring resilience, flexibility, and precise shape recovery, enhancing productivity and reliability.

Overall, nitinol wire's versatility makes it indispensable in industries where controlled deformation, resilience, and precise shape memory are critical requirements.

What are the Advantages of ASTM F2063 Medical Grade Nitinol Guide Wire?

The ASTM F2063 medical grade Nitinol guide wire offers several advantages:

Biocompatibility: It is non-toxic and well-tolerated by the body, minimizing risks of adverse reactions during medical procedures.

Flexibility: Nitinol guide wires are highly flexible, enabling navigation through complex anatomical pathways with minimal trauma to tissues.

Shape Memory: They exhibit shape memory properties, allowing them to return to their original shape after deformation, ensuring precise positioning during procedures.

Superelasticity: Nitinol wires are resilient to bending and kinking, providing durability and reliability in challenging medical environments.

Corrosion Resistance: They resist corrosion, maintaining their integrity and performance over extended periods of use.

Enhanced Visibility: Some variants are designed with radiopaque markers for enhanced visibility under medical imaging, aiding accurate placement.

These qualities make ASTM F2063 Nitinol guide wires ideal for use in a wide range of minimally invasive medical procedures, ensuring safety, efficacy, and patient comfort.

In conclusion, nitinol wire, especially ASTM F2063 medical grade nitinol guide wire, plays a pivotal role in modern technology and healthcare. Its unique combination of shape memory, superelasticity, and biocompatibility has revolutionized various industries, from medicine to aerospace. Understanding its manufacturing process, applications, and the advantages of medical grade nitinol guide wires provides valuable insights into why it remains a preferred material in critical applications.

References

-

"ASTM F2063 - 19 Standard Specification for Wrought Nickel-Titanium Shape Memory Alloys for Medical Devices and Surgical Implants." ASTM International, www.astm.org.

-

"Nitinol Medical Device Market Size, Share & Trends Analysis Report by Product (Stents, Guidewires, Others), by Application (Orthopedic, Cardiovascular), by Region (North America, Europe, APAC, LATAM, MEA), and Segment Forecasts, 2021 - 2028." Grand View Research, www.grandviewresearch.com.

-

"Shape Memory Alloys: A Practical Guide." Ed. Valeria A. Rojas. Woodhead Publishing, 2015.

.webp)

.webp)